Why Are There Glue Stains on the Surface of the Injection Mold?

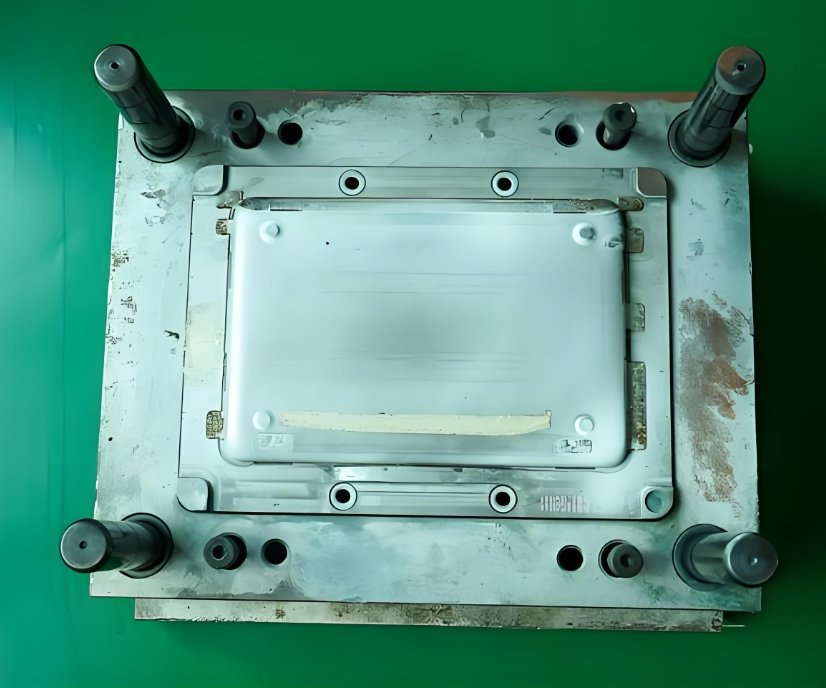

Glue stains on injection molds are a common issue. They can affect the quality of the final product. Mold makers must understand why these stains occur. Knowing the causes helps in preventing them. What Are Glue Stains? Glue stains appear as unwanted marks on the mold surface. They result from the adhesive used during the […]

Why Are There Glue Stains on the Surface of the Injection Mold? Read More »