Mold Maker Overcomes Injection Molding Issues in Medical Equipment

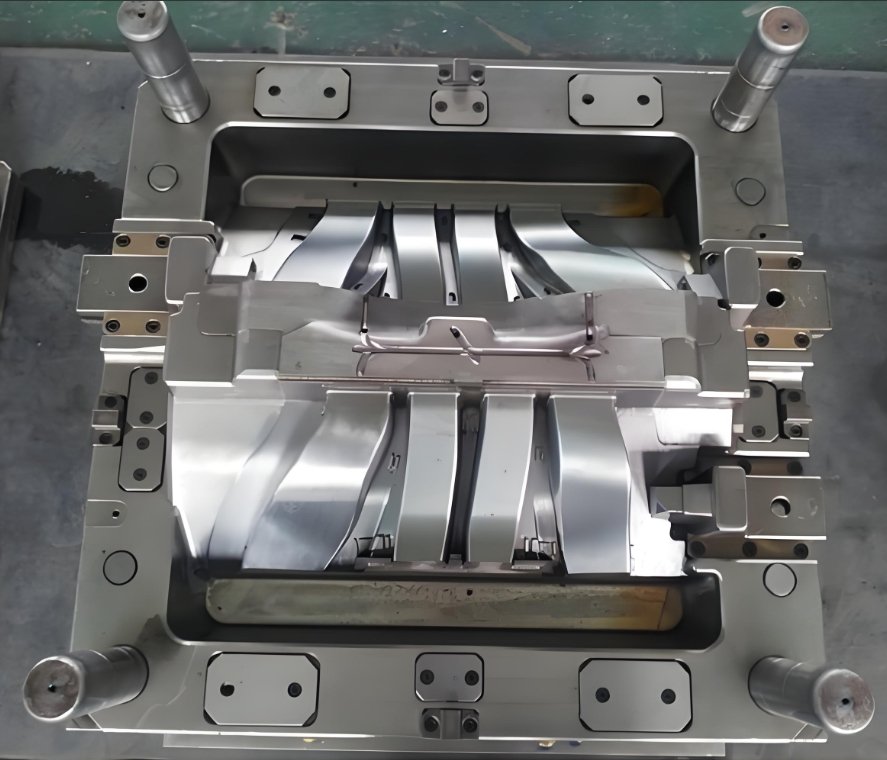

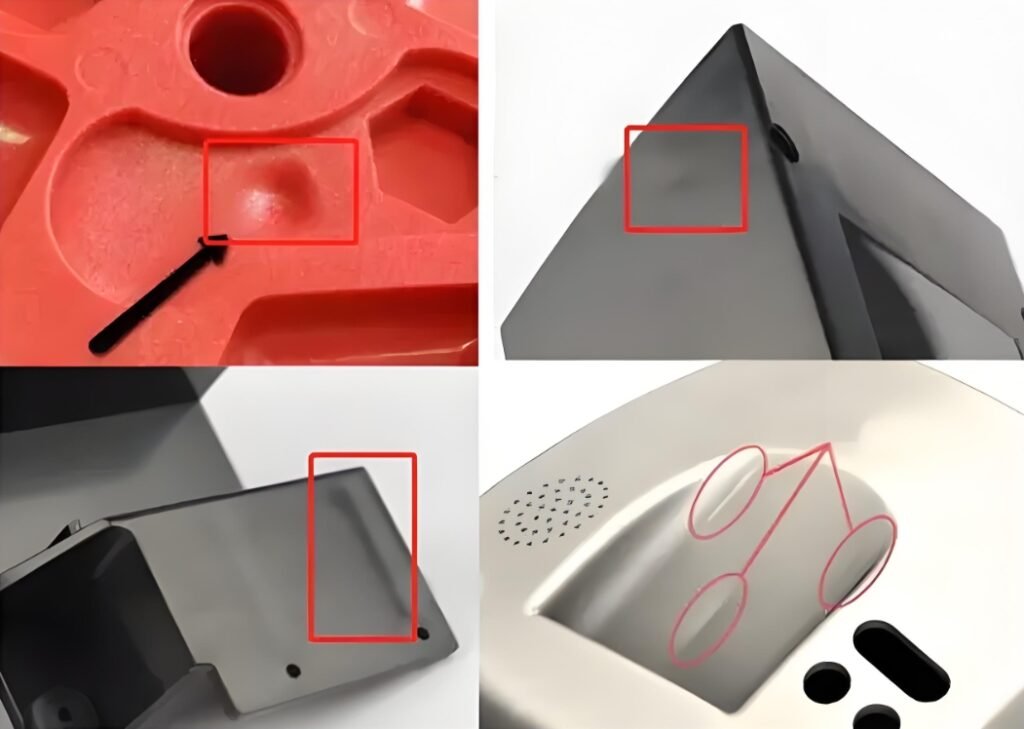

Popper Mold-Tech received a project to develop a mold for medical lighting equipment. The client required high heat resistance and lightweight material for the light housing. As a leading injection mould company, we accepted the challenge and proceeded with our reliable mold maker process. Understanding Client Requirements The lighting equipment needed to be lightweight, strong, […]

Mold Maker Overcomes Injection Molding Issues in Medical Equipment Read More »