The automotive industry evolves fast. Automotive injection molds play a crucial role. A skilled mold maker ensures precision and efficiency. New trends improve quality, speed, and sustainability.

1. Lightweight Materials for Fuel Efficiency

Why Lighter Parts Matter

Fuel efficiency is a priority. Automotive injection molds now focus on lightweight plastics. A mold maker selects durable yet light materials.

Common Lightweight Plastics

- Polypropylene (PP)

- Polycarbonate (PC)

- Glass-filled Nylon (PA)

- Carbon-fiber-reinforced composites

2. Advanced Simulation Technologies

How Simulations Improve Molding

Predicting mold behavior saves time. Automotive injection molds now rely on advanced simulations. A mold maker analyzes material flow and cooling.

Simulation Benefits

- Detects defects before production

- Reduces material waste

- Improves mold longevity

3. Smart Injection Molding Machines

Automation in Mold Manufacturing

Technology enhances efficiency. Automotive injection molds now use smart machines. A mold maker programs precise controls.

Features of Smart Molding Machines

- Real-time monitoring

- AI-driven quality checks

- Automated temperature adjustments

4. Sustainable and Recycled Materials

Eco-Friendly Plastic Alternatives

Green solutions matter. Automotive injection molds now use biodegradable and recycled plastics. A mold maker ensures sustainability.

Sustainable Materials Used

- Bio-based Polyamides

- Recycled ABS

- Eco-friendly Polyesters

5. Multi-Material Molding Techniques

Why Use Multiple Materials?

Combining materials increases strength. Automotive injection molds now feature overmolding and insert molding. A mold maker ensures seamless bonding.

Applications of Multi-Material Molding

- Soft-touch dashboards

- Hybrid structural components

- Seals and gaskets

6. Electric Vehicle (EV) Component Molding

How EVs Change Mold Design

EVs need specialized parts. Automotive injection molds now focus on lightweight and heat-resistant plastics. A mold maker adjusts designs for battery enclosures.

Popular EV Molding Applications

- Battery casings

- Lightweight interior panels

- High-voltage cable insulation

7. High-Precision 3D-Printed Molds

How 3D Printing Helps Mold Makers

Rapid prototyping speeds up production. Automotive injection molds now use 3D-printed prototypes. A mold maker tests designs faster.

Advantages of 3D-Printed Molds

- Faster mold development

- Lower prototype costs

- Improved design flexibility

8. Gas-Assisted Injection Molding

Why Use Gas Assistance?

Hollow parts reduce weight. Automotive injection molds now use gas injection. A mold maker ensures smooth, defect-free parts.

Common Applications

- Door handles

- Instrument panels

- Air ducts

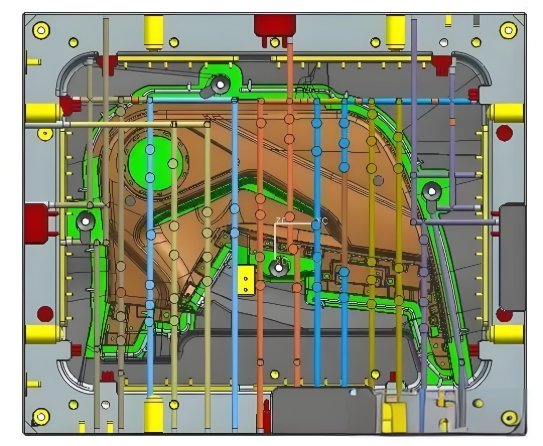

9. Improved Cooling Systems for Faster Cycles

How Cooling Affects Production

Faster cooling means quicker cycles. Automotive injection molds now use advanced cooling channels. A mold maker optimizes heat transfer.

Cooling Innovations

- Conformal cooling channels

- Beryllium copper inserts

- Water-assisted cooling

10. AI-Powered Quality Control

How AI Enhances Molding

Artificial intelligence improves precision. Automotive injection molds now include AI inspections. A mold maker ensures zero defects.

AI Applications in Injection Molding

- Automated defect detection

- Real-time production monitoring

- Predictive maintenance

11. Low-Volume and Custom Molding for Specialty Cars

Why Customization Matters

Luxury and specialty cars require unique parts. Automotive injection molds now cater to low-volume runs. A mold maker creates custom solutions.

Common Custom Molded Parts

- High-end interior trims

- Unique grille designs

- Specialty lighting components

12. Enhanced Mold Durability and Coatings

How Coatings Extend Mold Life

Wear resistance increases efficiency. Automotive injection molds now feature advanced coatings. A mold maker applies surface treatments.

Common Coatings Used

- Nickel plating

- Diamond-like carbon (DLC)

- Teflon coatings

13. Micro-Molding for Small Automotive Components

Why Smaller Parts Need Precision

Miniaturization improves vehicle efficiency. Automotive injection molds now create micro-components. A mold maker ensures high precision.

Examples of Micro-Molded Parts

- Sensor housings

- Small gears

- Electrical connectors

14. Faster Mold Development with Digital Twins

How Digital Twins Work

Virtual models reduce errors. Automotive injection molds now use digital twin technology. A mold maker refines designs before production.

Digital Twin Benefits

- Real-time mold performance monitoring

- Faster design validation

- Reduced development costs

15. Hot Runner Systems for Efficiency

Why Use Hot Runners?

Cold runners waste plastic. Automotive injection molds now favor hot runner systems. A mold maker minimizes material loss.

Hot Runner Benefits

- Faster cycle times

- Reduced waste

- Improved part consistency

The future of automotive injection molds looks promising. A skilled mold maker adapts to new trends. Advanced materials, smart technology, and sustainability drive innovation. Keeping up with these changes ensures top-quality vehicle components.