Vehicle design is more than function. Aesthetics play a huge role. Automotive Injection Molds create parts with flawless finishes. Expert Mold Makers ensure precision. They meet strict quality standards. This combination drives innovation in car designs.

Importance of Aesthetics in Automotive Design

1. First Impressions

Visual appeal captures attention instantly.

2. Brand Identity

Unique designs build strong recognition.

3. Consumer Preferences

Buyers favor attractive, stylish vehicles.

4. Competitive Edge

Sleek designs outshine rivals.

5. Increased Value

Well-designed cars command higher prices.

How Automotive Injection Molds Improve Aesthetics

1. Smooth Finishes

Injection molds ensure consistent surfaces.

2. Precision Crafting

Molds shape intricate details accurately.

3. Color Integration

Parts molded in vibrant, lasting hues.

4. Custom Textures

Molds add unique patterns to surfaces.

5. Complex Shapes

Intricate designs become possible.

Key Exterior Components Made with Injection Molds

1. Grilles

Bold designs enhance the front look.

2. Bumpers

Seamless shapes add sophistication.

3. Side Mirrors

Sleek finishes elevate the overall style.

4. Door Panels

Modern textures improve appearance.

5. Trim Pieces

Detailing boosts the car’s elegance.

Enhancing Interiors with Injection Molds

1. Dashboard Panels

Smooth, durable surfaces enhance comfort.

2. Seat Adjusters

Attractive, functional designs for ease.

3. Steering Wheels

Textured finishes add grip and style.

4. Air Vents

Stylish designs improve air circulation.

5. Console Covers

Refined finishes blend functionality with beauty.

Materials for Aesthetic Improvements

1. Polycarbonate

High strength and transparency for sleek parts.

2. ABS Plastics

Durable and easy to shape for intricate designs.

3. Polypropylene

Affordable with excellent finish options.

4. Nylon

Ideal for textured, robust components.

5. Polyurethane

Adds flexibility to aesthetic designs.

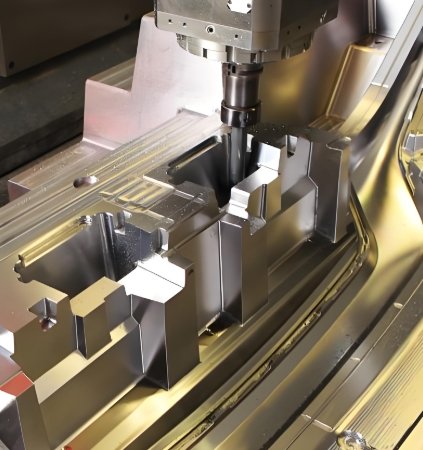

Innovations by Expert Mold Makers

1. 3D Prototyping

Quickly test and refine designs.

2. Laser Texturing

Create precise patterns on molds.

3. Multi-Color Molding

Add vibrant color combinations.

4. Automated Processes

Speed up production of detailed parts.

5. Sustainable Techniques

Eco-friendly methods enhance aesthetics.

Challenges in Creating Aesthetic Parts

1. Complex Shapes

Detailed designs require advanced molds.

2. Material Quality

Inferior materials reduce visual appeal.

3. Color Consistency

Uneven hues affect the look.

4. Surface Defects

Flaws lower the quality of finishes.

5. Tight Deadlines

High demand pressures production speed.

Overcoming Challenges

1. Advanced Equipment

Use cutting-edge tools for accuracy.

2. High-Grade Materials

Invest in premium plastics.

3. Strict Quality Control

Check every step of the process.

4. Expert Collaboration

Work closely with skilled Mold Makers.

5. Continuous Innovation

Adopt new techniques for better results.

Applications in Luxury Vehicles

1. Premium Finishes

Luxury brands demand flawless parts.

2. Unique Trim Pieces

Custom detailing for exclusivity.

3. Interior Accents

High-end textures add elegance.

4. Advanced Lighting Components

Sophisticated designs improve visibility.

5. Custom Grilles

Bold shapes define luxury car fronts.

Benefits of Using Automotive Injection Molds

1. Consistency

Every part meets exact standards.

2. Cost-Effectiveness

Molds produce large batches efficiently.

3. Durability

Parts withstand wear and tear.

4. Speed

Fast production for quick market entry.

5. Design Freedom

Create bold, intricate aesthetics.

The Future of Aesthetic Mold Making

1. AI-Driven Designs

Faster, smarter mold creation.

2. Eco-Friendly Materials

Sustainable parts without losing beauty.

3. Innovative Finishes

Advanced textures and coatings.

4. Integrated Lighting Features

Combine aesthetics with functionality.

5. Global Collaboration

Access expertise from top Mold Makers worldwide.

Automotive Injection Molds shape the future of vehicle aesthetics. Skilled Mold Makers transform innovative designs into reality. From sleek exteriors to refined interiors, molds deliver precision and beauty. The demand for customization drives advancements. With evolving technologies, automotive molds continue to enhance style and functionality.