Car interiors must be stylish and comfortable. Automotive Injection Molds create high-quality interior parts. Seats, dashboards, and door panels need precision. Expert Mold Makers design molds for a perfect fit. New materials and techniques improve comfort. Stylish designs make cars more attractive.

Importance of Injection Molding in Automotive Design

1. Precision and Quality

Cars need precise parts. Small errors affect fit and function. Automotive Injection Molds ensure perfect shapes.

2. Cost-Effective Production

Injection molding reduces costs. Large-scale production becomes efficient. Mold Makers design durable molds for long-term use.

3. Customization for Comfort

Modern cars focus on user experience. Soft-touch panels and ergonomic seats improve comfort. Injection molding allows design flexibility.

Key Automotive Interior Components Made with Injection Molds

1. Dashboards and Control Panels

- Must be durable and stylish

- Soft-touch materials enhance luxury

- Injection molds ensure smooth finishes

2. Door Panels

- Made with lightweight, strong plastics

- Includes built-in armrests and storage

- Textured surfaces for better grip

3. Seating Components

- Foam-injected seats improve comfort

- Molded plastic frames ensure durability

- Heated seat covers require precision molding

4. Steering Wheels

- Combines plastic and leather

- Ergonomic designs for better handling

- Injection molding ensures perfect contours

5. Air Vents and HVAC Controls

- Needs precise shapes for airflow

- Durable plastics resist heat

- Mold Makers design for easy assembly

6. Center Consoles and Cup Holders

- Must be strong and stylish

- Includes built-in compartments

- Injection molds ensure a seamless look

7. Floor and Roof Panels

- Lightweight for better fuel efficiency

- Insulated for noise reduction

- Molded for a perfect interior fit

Material Innovations in Automotive Injection Molds

1. Soft-Touch Plastics

- Improves comfort and luxury

- Reduces glare for better visibility

- Common in dashboards and armrests

2. Lightweight Composites

- Lowers vehicle weight

- Enhances fuel efficiency

- Used in door panels and roof lining

3. Sustainable and Recycled Materials

- Reduces environmental impact

- Maintains high strength and durability

- Popular in eco-friendly car models

4. High-Heat Resistant Plastics

- Essential for dashboards and control panels

- Prevents warping under sunlight

- Improves product lifespan

Role of Mold Makers in Interior Design

1. Creating High-Precision Molds

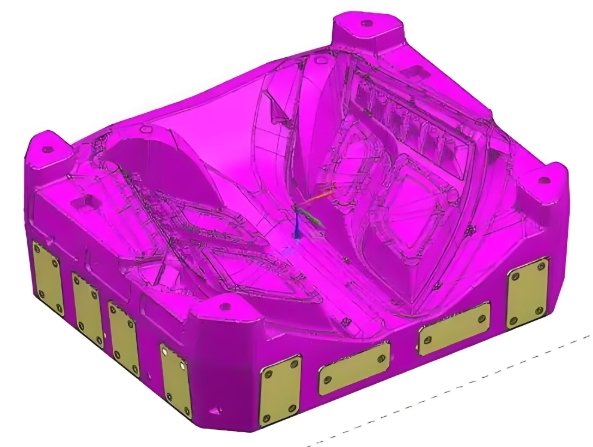

Mold Makers use advanced technology. They design molds with extreme accuracy. This ensures perfect part assembly.

2. Customization for Different Car Models

Every car has unique interior designs. Automotive Injection Molds adapt to different specifications. This allows full customization.

3. Enhancing Aesthetic Appeal

Textured surfaces improve style. Glossy and matte finishes add elegance. Mold Makers refine molds for visual appeal.

4. Increasing Durability

Interior parts face constant use. High-quality molds ensure longevity. Scratch-resistant materials improve durability.

Advanced Manufacturing Techniques in Automotive Molding

1. Multi-Component Molding

- Combines two or more materials

- Improves strength and flexibility

- Common in dashboards and steering wheels

2. Gas-Assisted Injection Molding

- Creates hollow sections

- Reduces weight without sacrificing strength

- Used in armrests and handles

3. Overmolding Technology

- Adds soft materials over hard plastics

- Improves grip and comfort

- Found in buttons, knobs, and handles

4. In-Mold Decoration (IMD)

- Integrates textures and colors

- Prevents peeling or fading

- Used in dashboards and panels

5. Insert Molding

- Embeds metal or electronic parts

- Used in control buttons and switches

- Increases functionality and durability

Customization Trends in Automotive Interiors

1. Personalization with Color and Texture

- Car buyers want unique interiors

- Mold Makers create molds for different finishes

- Matte, gloss, and soft-touch textures are popular

2. Smart and Interactive Controls

- Touchscreen panels require precision molds

- LED lighting elements add style

- Molds integrate electronics seamlessly

3. Luxury Features in Standard Models

- Heated and ventilated seats need special molds

- Leather-textured plastics improve luxury

- Automotive Injection Molds create premium looks at lower costs

Challenges in Automotive Injection Molding

1. Maintaining High Precision

- Small mold defects ruin interior parts

- Mold Makers use advanced CNC machining

2. Balancing Cost and Quality

- High-quality materials increase costs

- Manufacturers find the best balance

3. Ensuring Consistent Aesthetic Appeal

- Color consistency is crucial

- Special coatings prevent fading

4. Meeting Safety and Regulatory Standards

- Interior parts must be fire-resistant

- Crash-resistant plastics improve safety

Future of Automotive Injection Molds in Interior Design

1. Smart and Sustainable Materials

- Biodegradable plastics will increase

- Self-healing materials will extend part life

2. AI-Optimized Mold Designs

- Artificial intelligence will improve efficiency

- Predictive analysis will reduce mold defects

3. 3D Printing in Mold Making

- Faster prototyping with 3D-printed molds

- Reduces development time and costs

4. Integration of Augmented Reality (AR)

- AR assists in mold design

- Engineers visualize final products before production

Comfort and style define modern vehicles. Automotive Injection Molds shape high-quality interiors. Advanced materials and precision molding improve durability. Skilled Mold Makers create stylish, comfortable, and efficient car interiors. The future will bring even more innovation.