Rapid prototyping is vital in product development. It allows designers to test and refine their ideas quickly. For any injection mould company, creating prototypes is essential to ensure the final product meets quality standards. 3D printing is a popular choice for rapid prototyping today. Its speed, cost-effectiveness, and flexibility make it a game-changer.

What Is 3D Printing in Rapid Prototyping?

3D printing builds objects layer by layer. It uses computer-generated designs to create physical models. This method suits rapid prototyping because it speeds up the development process. For an injection mould company, this means faster project completion. It also reduces the chances of errors.

Key Benefits of 3D Printing for Rapid Prototyping

Faster Prototype Creation

3D printing dramatically reduces production time. Traditional methods take days or weeks. 3D printing can produce prototypes in hours. This speed is crucial for rapid prototyping. It enables injection mould companies to stay ahead of competitors.

Cost Savings

Traditional methods can be expensive. Tooling and material costs add up. 3D printing eliminates these expenses. Only the necessary materials are used. For an injection mould company, this means lower production costs.

Design Flexibility

3D printing allows unlimited creativity. Complex shapes and designs are easy to create. Adjustments are also simple. This flexibility enhances rapid prototyping. Every injection mould company benefits from this adaptability.

Improved Accuracy

3D printing offers high precision. Every layer is created with exact measurements. This ensures the prototype matches the design. It reduces errors and saves time in revisions.

Applications in Injection Mould Companies

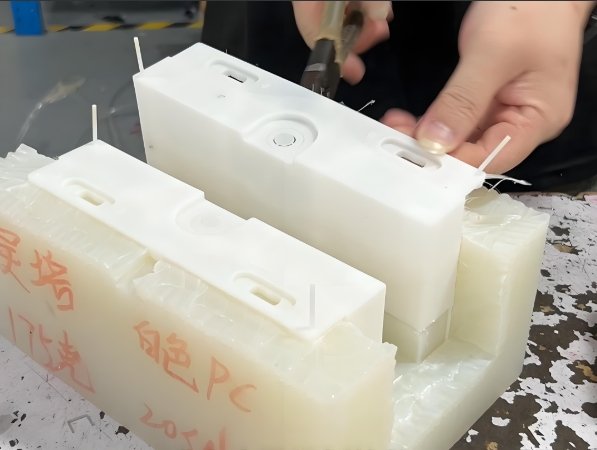

Testing Mold Designs

An injection mould company uses prototypes to test mold designs. 3D printing speeds up this process. It ensures molds are functional and accurate before production begins.

Small Batch Production

3D printing is ideal for small runs. When clients request limited prototypes, 3D printing delivers. This is valuable for rapid prototyping in niche markets.

Client Demonstrations

Prototypes help clients visualize their products. 3D printing allows an injection mould company to present designs faster. It improves communication and trust with customers.

Environmental Benefits

3D printing is sustainable. It minimizes waste by using only the required materials. This aligns with eco-friendly practices. For an injection mould company, this enhances brand reputation.

Overcoming Traditional Challenges

Reduced Dependence on Tooling

Traditional prototyping often requires expensive molds. This limits innovation. 3D printing removes this barrier. It supports creative designs without extra costs.

Shortened Feedback Loops

With 3D printing, changes can be implemented quickly. Engineers and designers can test multiple versions rapidly. This accelerates rapid prototyping and improves efficiency.

Challenges of 3D Printing in Rapid Prototyping

Despite its advantages, 3D printing has limits. Material options are not as diverse as traditional methods. Large-scale prototypes may require more time. However, ongoing advancements address these issues.

Why Injection Mould Companies Need 3D Printing

An injection mould company can’t ignore the benefits of 3D printing. It speeds up the process, reduces costs, and improves designs. Adopting this technology gives companies a competitive edge in rapid prototyping.

Future of 3D Printing in Rapid Prototyping

The future is promising. 3D printing continues to evolve. Faster printers and more material options are emerging. For injection mould companies, this means even better tools for rapid prototyping.

3D printing is transforming rapid prototyping. It offers speed, accuracy, and cost savings. For every injection mould company, it’s a valuable tool. Embracing this technology ensures success in today’s competitive market.