Home Appliance Plastic Housings Made Easy

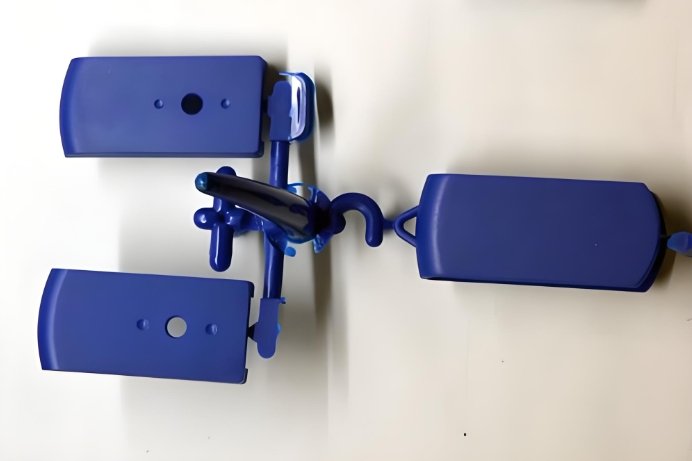

Modern home appliances rely not only on internal functionality but also on strong, attractive outer shells. These outer shells, known as plastic housings, protect the device and give it a finished look. The method that makes these housings both practical and cost-effective is Housing Injection Molding. When combined with the work of a skilled Mold […]