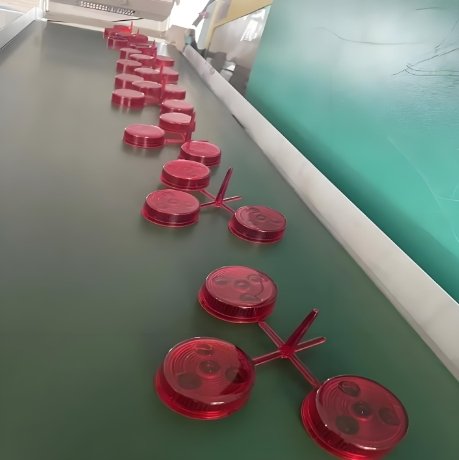

How Recycled Materials Can Improve Electronic Molding Sustainability

Sustainability is no longer a choice.It’s a necessity.As industries shift toward greener methods, Electronic Injection Molding plays a critical role in reducing environmental impact.One powerful way to make the process more eco-friendly is by using recycled materials.When paired with the expertise of a skilled Mold Maker, recycled plastics can lead to efficient, cost-effective, and environmentally […]

How Recycled Materials Can Improve Electronic Molding Sustainability Read More »