How to Achieve High Precision in Electronic Injection Molding

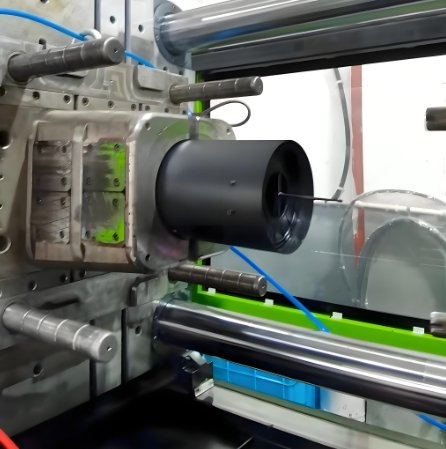

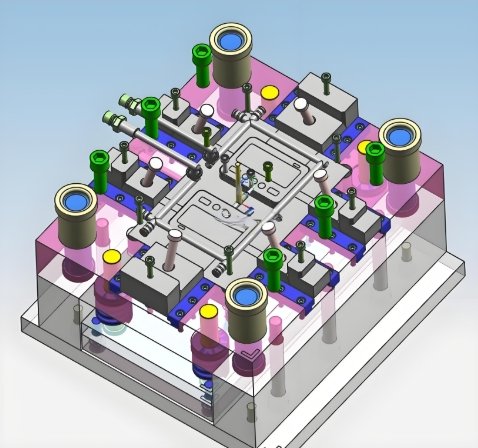

Precision is everything in electronic components. Electronic injection molding requires high accuracy to ensure parts fit, function, and last. Small tolerances and fine details can make a huge difference. A mold maker uses advanced techniques to ensure each part is made with perfect precision. 1. Understanding Precision in Electronic Injection Molding 1.1 What is Precision […]

How to Achieve High Precision in Electronic Injection Molding Read More »