Speeding Up Innovation with Rapid Prototyping

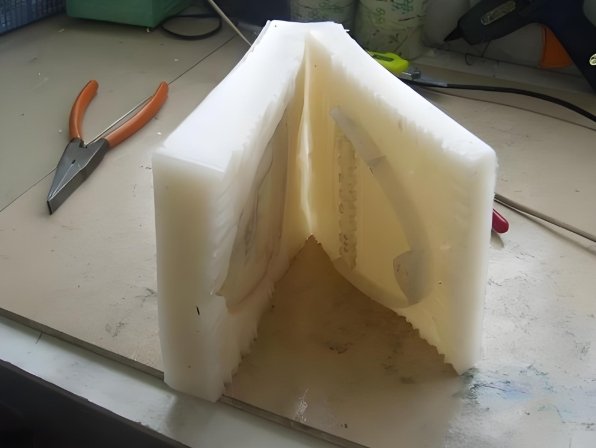

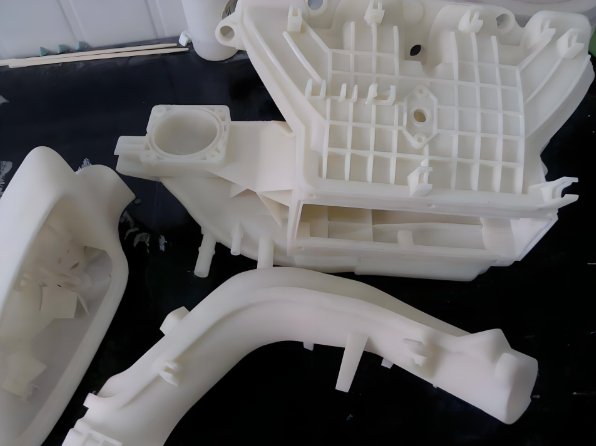

Innovation drives businesses forward. Speed is essential to stay ahead. Rapid Prototyping boosts development timelines. It lets designers test ideas fast. Partnering with an Injection Mould Company makes the process seamless. What Is Rapid Prototyping? Rapid Prototyping creates physical models quickly. It uses advanced methods like 3D printing or SLA. Designers turn concepts into tangible […]