Key Advantages of Injection Mould Company for Mass Production

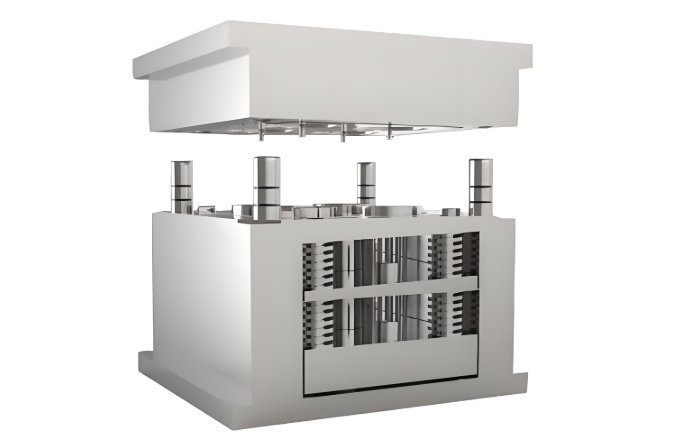

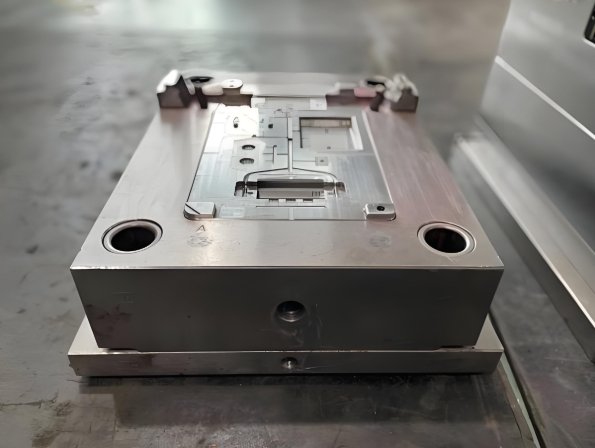

An injection mould company offers significant advantages for mass production. Injection molding is a highly efficient process for making large quantities of parts. With the help of skilled mold makers, this process creates consistent, high-quality products quickly. Whether it is for consumer goods, automotive parts, or electronics, injection molding is ideal for large-scale production. The […]

Key Advantages of Injection Mould Company for Mass Production Read More »