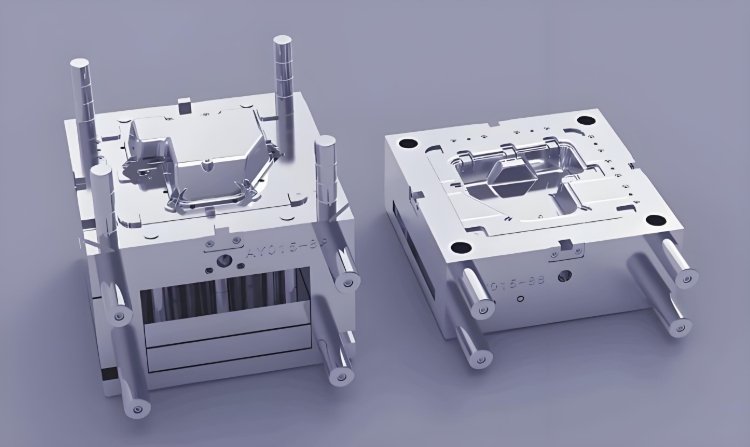

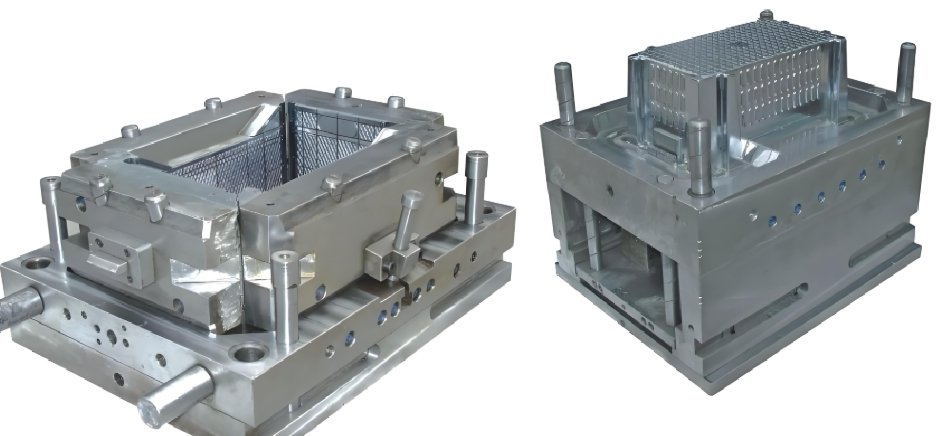

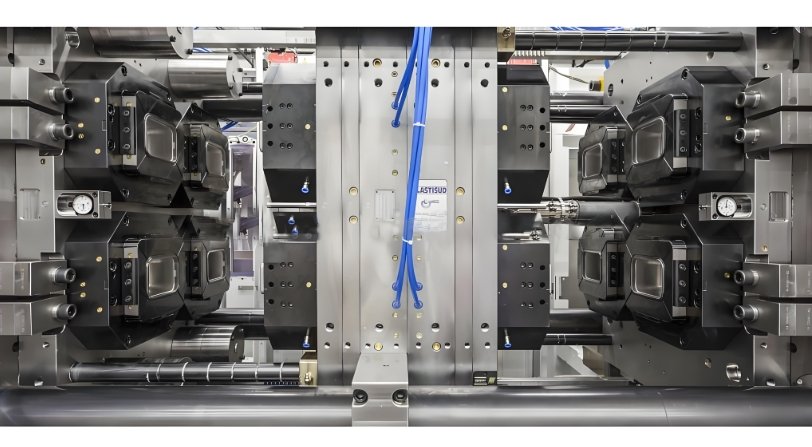

Injection Mould Company for Consistent and Repeatable Results

When it comes to injection molding, one of the most crucial aspects of the process is consistency. Every product must meet strict standards for quality and precision. To achieve these standards, partnering with a reliable injection mould company is essential. A professional mold maker ensures that every mold is created accurately, producing consistent results every […]

Injection Mould Company for Consistent and Repeatable Results Read More »