High-volume manufacturing requires precise planning and the right partners. Selecting a reliable injection mould company is essential. Large production runs depend on consistent quality, efficiency, and robust equipment. Here, we explore the key factors in choosing the right injection mould company and why injection molding and a skilled mold maker matter for high-volume success.

What is Injection Molding?

Injection molding is a manufacturing process where melted plastic is injected into a mold to form parts. Injection molds create complex shapes in a single step. This process is ideal for producing large quantities. Each cycle produces identical, high-quality parts. The right injection mould company ensures efficiency, quality, and durability. Consistent parts matter most in high-volume production.

Why Choose Injection Molding for High-Volume Manufacturing?

High-volume runs require cost efficiency and speed. Injection molding is ideal for this. It produces hundreds to thousands of parts in a short time. Unlike other processes, injection molding maintains accuracy throughout. Once the mold is created, each cycle costs less. Choosing the right injection mould company reduces errors and increases speed. Precision is essential when making large quantities.

Key Factors When Choosing an Injection Mould Company

1. Expertise in High-Volume Injection Molding

Experience matters in high-volume injection molding. Look for companies with a proven record. A qualified injection mould company understands the unique needs of large runs. They ensure your project scales without issues. The best companies offer guidance at every stage. Their experience reduces risks and helps avoid costly delays.

2. Quality Mold Makers

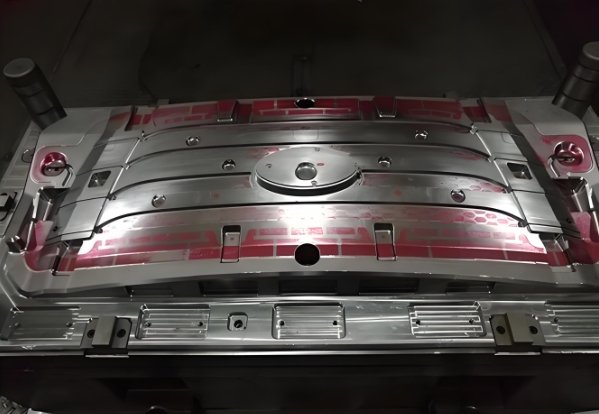

A skilled mold maker creates durable and precise injection molds. The quality of the mold affects every part it produces. Injection molds for high-volume runs need to withstand repeated use. Inferior molds wear quickly, leading to part defects. Choose a company with in-house mold makers or close partnerships with reputable mold makers. They guarantee each mold is made to last.

3. Advanced Machinery and Technology

A modern injection mould company uses advanced machinery. Look for companies with high-tech injection molding machines. These machines provide greater control and precision. Advanced machinery allows for faster cycles. Modern technology also enables real-time quality checks. This ensures consistency, especially for high-volume needs.

4. Materials Expertise

The right injection mould company should offer a variety of materials. Different products need different types of plastic. For example, automotive parts may need high-strength plastic, while medical parts need safe, durable materials. Skilled mold makers know how each material behaves during injection molding. They help you choose the best material for your product’s needs. Quality materials improve durability and reduce waste.

5. Efficient Production Process

Efficiency is essential for high-volume production. A professional injection mould company has a streamlined process. They reduce setup times, optimize cycles, and prevent delays. Efficient production saves money and reduces waste. A company focused on efficiency helps complete your project on time. This is especially important in high-volume manufacturing.

6. Quality Control and Testing

Quality control ensures each part meets exact standards. High-volume runs require strict quality checks. Look for an injection mould company with an established testing process. They inspect each mold before production. They test parts for consistency during production. Quality control prevents errors and reduces costs. With high-quality injection molds, every part matches your specifications.

Advantages of Choosing a Quality Injection Mould Company

A reliable injection mould company offers many benefits for high-volume production. The right company saves you time and money. Here’s how:

Cost Efficiency

Injection molding is cost-effective for large runs. Once a mold is made, each cycle costs less. The best mold makers design molds for maximum efficiency. High-quality molds reduce waste and energy costs. Choosing a reliable injection mould company minimizes long-term costs.

Faster Production Cycles

Large runs need quick production. Professional injection molding companies have optimized cycles. Advanced machinery speeds up each stage. Fast cycles allow more parts in less time. This reduces overall production time.

Consistent Quality

Quality is key in high-volume manufacturing. Poor-quality molds cause part defects. Experienced mold makers ensure molds are precise. Consistent quality prevents wasted materials and time. This is crucial when making thousands of identical parts.

Long Mold Life

High-quality injection molds last longer. A durable mold supports more cycles without wear. Investing in a skilled injection mould company reduces the need for replacement molds. This lowers costs over time.

Customization for Specific Needs

A skilled injection mould company offers customization. High-volume manufacturing often requires unique features. Custom injection molds ensure each part fits exact specifications. A reliable company works closely with you to create molds suited to your product’s needs.

Steps to Choosing the Right Injection Mould Company

1. Research Company Reputation

Look for injection mould companies with a strong reputation. Read reviews and ask for client references. A reliable company will have positive feedback. This shows they deliver quality and meet deadlines.

2. Evaluate Their Experience

Experience matters in injection molding. Choose a company with years of experience. Experienced companies handle complex projects. They know how to manage high-volume runs effectively.

3. Check Technology and Equipment

Modern technology improves efficiency. Ensure the injection mould company uses advanced equipment. Up-to-date machinery provides better results. High-tech equipment ensures precision and speed.

4. Assess Material Options

Different products require different materials. Choose a company with a variety of plastic options. This flexibility allows better customization. It also ensures durability and product quality.

5. Request a Prototype

Before committing, request a prototype. A prototype allows you to assess the quality firsthand. Reputable injection mould companies offer prototypes for testing. This step ensures your expectations are met.

6. Discuss Turnaround Time

High-volume runs need timely delivery. Ask about turnaround times. A professional injection mould company provides clear timelines. This ensures your project stays on schedule.

7. Consider Cost and Value

Cost matters, but so does value. Choose a company offering quality at a fair price. Avoid companies with very low prices. Low-cost molds may lack durability. Investing in quality injection molds saves money long-term.

Why a Skilled Mold Maker Matters

A skilled mold maker ensures your mold is high-quality. They design injection molds for durability and precision. Experienced mold makers understand high-volume needs. They create molds that last through multiple cycles. This reduces defects and extends mold life. Choosing a company with skilled mold makers guarantees long-term success.

The Role of Injection Molding in High-Volume Success

Injection molding is essential for high-volume manufacturing. It allows fast, consistent, and cost-effective production. The right injection mould company ensures every part is made accurately. Quality molds and skilled mold makers are the foundation of high-volume success. A reliable partner in injection molding helps bring your product to market faster and with better quality.

Conclusion

Choosing an injection mould company for high-volume manufacturing requires careful consideration. Look for experience, advanced technology, and efficient production processes. The right mold maker and high-quality injection molds are essential for consistency and durability. By selecting a reliable injection mould company, you ensure your project runs smoothly from prototype to final production. Make your choice wisely, and set your product up for long-term success in the market.