In today’s competitive manufacturing world, finding the right Injection Mould Company is crucial. Your choice can significantly impact your product’s quality and your company’s reputation. One key factor to consider when selecting a supplier is their quality certification. Working with a certified Mold Maker can ensure that the Injection Molds you use are of the highest quality. Let’s explore why quality certification matters and how it benefits your business.

What is Quality Certification?

Quality certification is an official recognition that a company adheres to certain standards. These standards ensure that the company meets specific quality benchmarks in production processes, safety, and product outcomes. Injection Mould Companies with quality certification have undergone rigorous assessments to verify that their manufacturing processes are reliable and consistent.

For example, common quality certifications include:

- ISO 9001: A global standard for quality management systems.

- ISO 14001: Certification for environmental management.

- IATF 16949: Certification for the automotive industry, focusing on quality standards for parts and materials.

Why Does Quality Certification Matter for Injection Mould Companies?

Choosing an Injection Mould Company with quality certification guarantees several advantages. Here’s why it matters:

- Consistency in Quality Certified companies follow well-defined processes. They maintain strict controls over every step of production. As a result, they produce consistent, high-quality Injection Molds. You can rely on them to deliver the same high standard each time.

- Reduced Risk of Defects With quality certification, a company must pass audits and meet stringent quality standards. This helps reduce the risk of defects in Injection Molding. Products will be produced with fewer flaws, leading to fewer returns and complaints.

- Trust and Reliability A certified Mold Maker will have a proven track record of delivering reliable products. When working with a certified company, you’re partnering with a business that has demonstrated its commitment to quality. This builds trust and strengthens the business relationship.

- Compliance with Industry Standards Many industries, like automotive, medical, and consumer electronics, require specific quality standards. By working with a certified Injection Mould Company, you can ensure that your Injection Molds meet the necessary industry regulations. This can be crucial for securing contracts or passing compliance checks.

The Process of Quality Assurance in Injection Moulding

For an Injection Mould Company to earn certification, they must demonstrate their ability to maintain quality at every stage of the Injection Molding process. Here’s a breakdown of the typical steps they take:

1. Material Selection

The right material is essential for producing high-quality Injection Molds. Certified companies select materials that meet specific performance requirements. They also maintain a strict process for testing material properties before production begins.

2. Design and Engineering

Design is the first step in creating Injection Molds. A certified Mold Maker will use advanced software to create precise designs. These designs are evaluated for durability and accuracy before production.

3. Mold Manufacturing

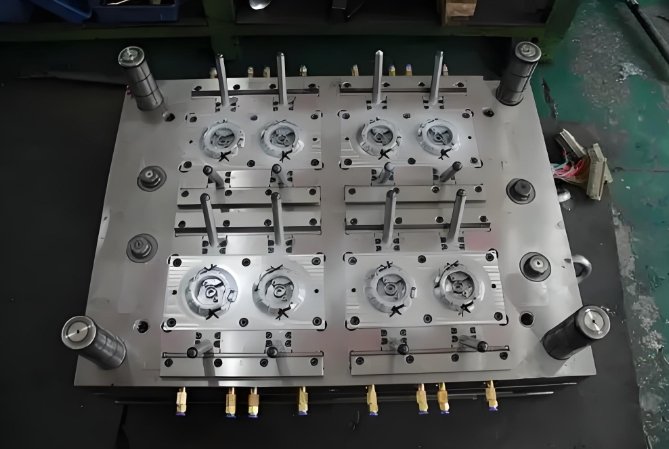

Once the design is finalized, the Injection Mould Company starts creating the molds. Certified companies use high-precision machines and processes to ensure the molds are made to exact specifications. Quality assurance checks are built into the manufacturing process to catch errors early.

4. Injection Molding Process

During the Injection Molding process, the material is injected into the mold under pressure. Certified companies monitor every step carefully, adjusting the temperature, pressure, and timing to ensure the product meets quality standards.

5. Post-production Testing

After the molding process, the products are tested for defects. This includes checking the dimensions, strength, and finish of each part. Companies with quality certification conduct thorough testing to ensure that every product is of the highest quality.

How to Choose the Right Injection Mould Company

When selecting an Injection Mould Company, look for these signs of quality certification and expertise:

- Check for Certification Always verify that the company holds relevant certifications. This proves their commitment to quality and adherence to industry standards.

- Examine Their Track Record A reputable Mold Maker will have a history of successful projects. Ask for case studies or examples of past work to see their capabilities.

- Evaluate Their Technology and Equipment Certified Injection Mould Companies invest in advanced technology and equipment to meet quality standards. They use state-of-the-art machinery to produce accurate and reliable molds.

- Consider Customer Feedback Reviews and testimonials from previous clients can give you insight into the company’s reliability and quality. Look for companies that consistently receive positive feedback.

- Assess Their Communication and Support Quality companies maintain open communication with clients. They are transparent about timelines, costs, and any challenges that may arise during the project. Good customer service is a key indicator of a company’s professionalism.

Benefits of Choosing a Certified Injection Mould Company

Working with a certified Injection Mould Company offers many benefits:

- Higher Efficiency Certified companies use well-organized processes, which improve efficiency and reduce waste. This means quicker turnaround times for your projects.

- Cost Savings While certified companies may charge a premium, their focus on quality often leads to long-term cost savings. Fewer defects and returns mean lower production costs.

- Competitive Advantage If you work in an industry where product quality is essential, using a certified Mold Maker can give you a competitive edge. Certified molds meet higher standards, which can make your products stand out in the market.

- Global Compatibility Certification helps ensure that the Injection Molds meet international quality standards. This is crucial if you plan to sell your products globally. Certified molds will pass inspections in different countries, making them easier to distribute internationally.

Choosing the right Injection Mould Company is crucial for ensuring the quality and success of your products. By working with a company that has the right quality certifications, you can reduce risks, improve product consistency, and meet industry standards. Certified Mold Makers are experts who follow strict quality assurance processes, resulting in better Injection Molds and faster, more reliable production.

In the competitive world of manufacturing, quality should always come first. Partnering with a certified Injection Mould Company gives you the assurance that your products will meet the highest standards, reducing costs and improving your brand reputation.