Manufacturers seek lower costs. Automotive injection molds offer efficiency. A skilled mold maker optimizes production. Smart strategies reduce waste. Cost-effective solutions improve profitability.

Why Cost Efficiency Matters in Automotive Injection Molding

1. Competitive Market Demands

Auto parts must stay affordable. Automotive injection molds lower expenses. A mold maker ensures cost control.

2. High Production Volumes

Cars require many parts. Automotive injection molds handle mass production. A mold maker ensures efficiency.

3. Raw Material Costs

Plastic prices fluctuate. Automotive injection molds must optimize usage. A mold maker selects cost-effective materials.

4. Labor and Overhead Expenses

Manufacturing involves high costs. Automotive injection molds benefit from automation. A mold maker reduces manual work.

Cost-Saving Strategies in Automotive Injection Molding

1. Optimizing Mold Design

Better design lowers costs. Automotive injection molds need precision. A mold maker reduces errors.

2. Using Multi-Cavity Molds

More cavities mean more parts. Automotive injection molds increase output. A mold maker enhances efficiency.

3. Reducing Cycle Times

Faster cycles save money. Automotive injection molds improve productivity. A mold maker optimizes cooling.

4. Selecting Cost-Effective Materials

Material choice impacts cost. Automotive injection molds use affordable plastics. A mold maker ensures durability.

5. Implementing Automated Processes

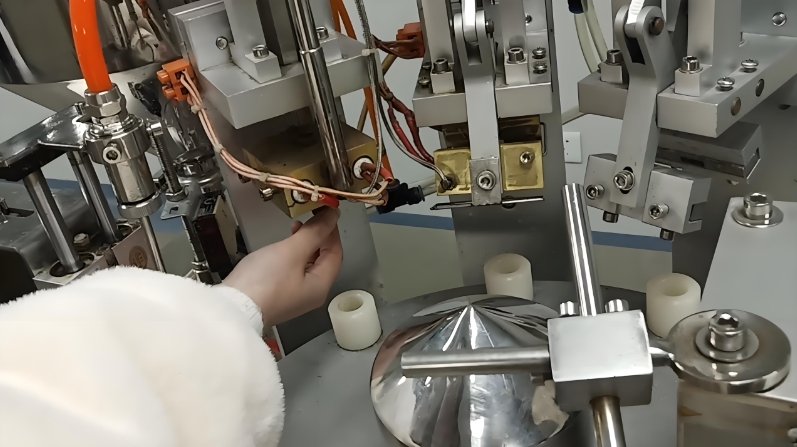

Automation reduces labor. Automotive injection molds run smoothly. A mold maker integrates smart systems.

6. Reusing and Recycling Materials

Waste increases costs. Automotive injection molds use recycled plastics. A mold maker supports sustainability.

7. Preventive Mold Maintenance

Damaged molds slow production. Automotive injection molds need regular checks. A mold maker prevents failures.

8. Improving Cooling Systems

Better cooling speeds up cycles. Automotive injection molds need efficient channels. A mold maker ensures fast cooling.

Reducing Material Costs in Injection Molding

1. Choosing the Right Plastic

Different plastics have different costs. Automotive injection molds require the best value. A mold maker selects wisely.

2. Using Recycled Materials

Recycled plastic saves money. Automotive injection molds use eco-friendly materials. A mold maker reduces waste.

3. Reducing Material Waste

Less waste means lower costs. Automotive injection molds must minimize excess. A mold maker optimizes design.

4. Lightweighting Strategies

Lighter parts need less plastic. Automotive injection molds create thinner parts. A mold maker ensures strength.

Enhancing Efficiency in Production

1. Automation in Molding

Robots improve efficiency. Automotive injection molds work faster. A mold maker reduces labor costs.

2. Smart Monitoring Systems

Sensors track performance. Automotive injection molds detect issues early. A mold maker ensures smooth operation.

3. Efficient Mold Changes

Fast mold changes save time. Automotive injection molds use quick-swap systems. A mold maker streamlines production.

4. Energy-Efficient Machinery

Less energy means lower costs. Automotive injection molds run on efficient machines. A mold maker reduces power use.

Longevity and Maintenance of Molds

1. Proper Mold Storage

Good storage prevents damage. Automotive injection molds last longer. A mold maker ensures safe handling.

2. Regular Cleaning and Inspection

Dirt causes defects. Automotive injection molds need regular cleaning. A mold maker avoids breakdowns.

3. Coating for Durability

Coatings prevent wear. Automotive injection molds stay strong. A mold maker reduces replacement costs.

4. Repair Over Replacement

Fixing saves money. Automotive injection molds can be repaired. A mold maker extends mold life.

Reducing Defects and Scrap

1. Improving Mold Design

Bad design increases defects. Automotive injection molds need precise engineering. A mold maker minimizes errors.

2. Controlling Process Variables

Temperature affects quality. Automotive injection molds require stable settings. A mold maker ensures consistency.

3. Using High-Quality Raw Materials

Poor materials cause defects. Automotive injection molds need quality plastics. A mold maker ensures durability.

4. Training Skilled Workers

Skilled workers reduce mistakes. Automotive injection molds require proper handling. A mold maker trains teams.

Future Trends in Cost-Saving for Automotive Injection Molds

1. AI in Mold Design

AI improves accuracy. Automotive injection molds benefit from smart systems. A mold maker reduces design flaws.

2. 3D Printing for Prototyping

Prototyping speeds up testing. Automotive injection molds develop faster. A mold maker avoids expensive trials.

3. Sustainable Manufacturing Practices

Eco-friendly solutions cut costs. Automotive injection molds use green materials. A mold maker supports sustainability.

4. Advanced Robotics in Molding

Automation boosts speed. Automotive injection molds work efficiently. A mold maker integrates smart robotics.

Reducing costs is essential. Automotive injection molds improve efficiency. A skilled mold maker ensures savings. Smart design, automation, and material selection lower expenses. The future of automotive injection molds focuses on sustainability and innovation.