In today’s competitive market, businesses need reliable manufacturing solutions. For products that require precision and durability, many turn to a specialized Injection Mould Company. Custom Injection Molding services play a vital role in creating high-quality parts, enhancing product value and consistency. Whether it’s complex shapes or intricate designs, a skilled Mold Maker can make all the difference. Here’s what you need to know about the services offered by custom Injection Mould Companies and how they benefit your projects.

Why Choose a Custom Injection Mould Company?

A custom Injection Mould Company provides tailored solutions. Unlike standard molds, custom Injection Molds are designed to fit the specific requirements of your product. They focus on precise Injection Molding processes, ensuring every part meets high-quality standards. Custom molds maximize efficiency, minimize waste, and improve the overall performance of your product.

Using a specialized Mold Maker also means you get expertise in materials and processes. A professional Injection Mould Company evaluates product specifications to choose the right material and design.

Key Custom Services Offered by an Injection Mould Company

Custom Injection Mould Companies offer a variety of services, each aimed at different stages of the manufacturing process. These services are essential for companies that need detailed parts made with high accuracy.

1. Mold Design and Prototyping

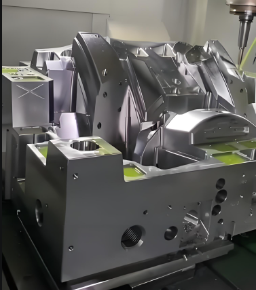

The first step in Injection Molding is creating a precise mold design. A skilled Mold Maker will design Injection Molds that match your product’s requirements. They use advanced software and testing to ensure the mold will work efficiently in production.

Prototyping is also part of this stage. Custom Injection Mould Companies create prototypes to test the mold design. This helps in identifying issues early, saving time and costs.

2. Material Selection

Choosing the right material is crucial in Injection Molding. Different products require different materials, such as plastics, thermoplastics, or resins. An experienced Mold Maker can recommend the best material based on factors like durability, flexibility, and temperature resistance.

A custom Injection Mould Company works with various materials to fit diverse needs. The correct material choice can enhance product quality and lifespan.

3. **Precision Injection Molding

Precision is vital in Injection Molding. Custom Injection Mould Companies focus on high-quality processes, ensuring that each part has accurate dimensions. They use advanced machines to ensure that every piece is consistent. Precise Injection Molding reduces errors and ensures that parts will fit perfectly with other components.

4. Multi-Cavity Molds

For high-volume production, a custom Injection Mould Company may suggest multi-cavity molds. This type of mold creates multiple parts in a single cycle. It speeds up production and can reduce costs per unit.

A Mold Maker with experience in multi-cavity molds ensures that each cavity produces identical parts. This consistency is important in industries that require large quantities of identical parts, like automotive or consumer goods.

5. Complex Part Molding

Many products today have complex shapes that are difficult to produce. A custom Injection Mould Company specializes in complex part molding. They design molds that can create intricate parts with multiple features. Complex part molding is common in the electronics, medical, and aerospace industries.

Skilled Mold Makers create custom Injection Molds to ensure even complex designs are produced accurately. They understand the complexities and challenges involved in producing detailed parts and can handle these challenges effectively.

6. Overmolding and Insert Molding

Overmolding and insert molding are advanced techniques in Injection Molding. Overmolding involves creating a part with two or more materials, while insert molding involves embedding components like metal or other parts into the mold.

These methods are useful in products that need added functionality or durability. A custom Injection Mould Company can help you create complex products with multiple materials, making the process efficient and high-quality.

7. Quality Control

Custom Injection Mould Companies emphasize quality control. Throughout the production process, they inspect parts to ensure they meet specifications. The right Injection Mould Company uses detailed quality checks, preventing defects from reaching the final stages. This saves on potential rework or product recalls.

A professional Mold Maker takes quality seriously, understanding that each part must be flawless. They invest in inspections to confirm that each product meets industry standards.

Advantages of Custom Injection Molding Services

Opting for a custom Injection Mould Company has numerous benefits, particularly for projects requiring precision. Here are some of the key advantages:

1. Enhanced Product Quality

A custom Mold Maker uses specialized tools and techniques, producing high-quality Injection Molds. Custom Injection Molding improves product quality, as the molds are designed specifically for your project. The accuracy of the mold ensures that every part produced has a consistent shape and size.

2. Flexibility in Design

Working with a custom Injection Mould Company allows flexibility. Whether you need complex designs or unique shapes, a custom Mold Maker can provide solutions. They create molds based on detailed specifications, which is crucial for industries requiring specialized parts.

3. Cost Savings in Production

While custom Injection Molds may have a higher initial cost, they save money in the long term. Custom molds reduce the need for modifications and increase the efficiency of production. For large orders, the cost per unit becomes lower due to the efficiency of the process.

4. Improved Efficiency

Custom Injection Molding services enhance production efficiency. Multi-cavity molds and optimized designs allow for faster production without sacrificing quality. A custom Injection Mould Company can help you streamline production, reducing lead times and improving overall productivity.

5. Access to Expert Advice

A specialized Injection Mould Company offers expert guidance. From design to material selection, a skilled Mold Maker can advise you on the best solutions for your project. This expertise ensures you get the best results for your investment.

Choosing the Right Custom Injection Mould Company

Selecting the right Injection Mould Company is essential. Look for companies with proven experience, skilled Mold Makers, and a strong focus on quality. Here are some tips to help you find the right fit:

- Check Experience: Choose a company with experience in your industry.

- Assess Capabilities: Make sure they can handle complex designs or specific materials.

- Quality Control: Reliable companies have strong quality assurance practices.

- Technical Support: Look for companies that provide ongoing support and maintenance.

Working with the right Injection Mould Company helps your business get the quality and efficiency you need.

Final Thoughts

A custom Injection Mould Company offers valuable services for companies needing precision and reliability. Custom Injection Molding ensures that each product is created to meet specific requirements. From mold design to quality control, a professional Mold Maker guides every step, creating solutions that improve efficiency, quality, and cost-effectiveness.

If you want your products to stand out in the market, consider working with a custom Injection Mould Company. With their expertise, you can ensure that every part of your product is flawless, efficient, and ready for the challenges of the modern market.