The automotive industry is constantly changing. New technologies and manufacturing processes are pushing boundaries. One of the most important innovations is Automotive Injection Molds. These molds are customizable and play a crucial role in vehicle manufacturing. A Mold Maker creates these molds with precision to meet specific needs. This article explores how customizable injection molds shape the future of vehicle production.

What Are Automotive Injection Molds?

1. Basic Definition

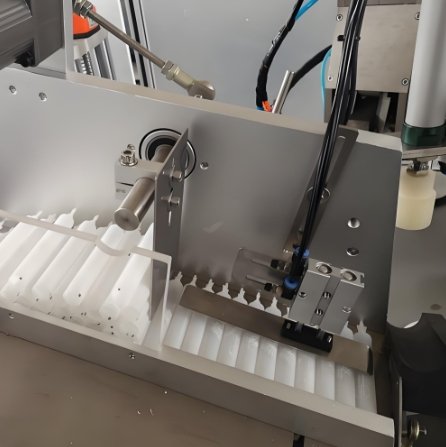

Automotive Injection Molds are used to produce various car parts. The process involves injecting molten material into a mold. This material then hardens to form the desired shape.

2. Mold Design

The design of the mold is crucial. It affects the final part’s quality and performance. Custom molds are made to meet specific requirements, from strength to appearance.

Why Customization Matters

1. Precision Engineering

Customized molds ensure parts are made with the utmost accuracy. This is crucial for the automotive industry. Even small variations can affect the vehicle’s performance.

2. Enhanced Functionality

Every vehicle part has a unique function. Custom molds allow for intricate designs that fulfill specific functions. For example, parts that need to withstand high temperatures or heavy stress can be created with custom molds.

3. Cost Efficiency

Custom molds reduce waste and optimize material usage. This leads to lower production costs. The ability to use the exact amount of material needed also results in better resource management.

Types of Customizable Automotive Injection Molds

1. Multi-Cavity Molds

Multi-cavity molds allow for the simultaneous production of multiple parts. This increases production speed while maintaining high precision.

2. Family Molds

Family molds can produce different parts from the same mold. These parts share similar features but may vary in size or shape. Family molds are great for creating several components at once.

3. Stack Molds

Stack molds feature multiple mold cavities stacked on top of one another. This is perfect for producing larger quantities of parts.

4. Hot Runner Molds

Hot runner molds maintain the temperature of the material as it moves through the system. These molds reduce waste and improve cycle times.

Mold Maker Expertise in Customization

1. Complex Designs

A Mold Maker must be skilled in handling complex designs. Modern vehicles have intricate parts that require precision. Custom molds are tailored to these designs.

2. Material Selection

Choosing the right material is crucial. A Mold Maker selects materials based on the specific requirements of each part. This can range from plastics to metals and composites.

3. Prototyping and Testing

Before full-scale production, prototypes are made. These prototypes are tested for fit, function, and durability. Custom molds allow for quick adjustments to designs based on test results.

Applications of Customizable Automotive Injection Molds

1. Exterior Parts

Custom molds are used to create exterior parts like bumpers, grilles, and fenders. These parts must be durable, lightweight, and aesthetically appealing.

2. Interior Components

Injection molds are also used for interior parts. Customizable molds help create dashboards, consoles, and door panels with high precision.

3. Engine Components

Certain engine components need to withstand extreme heat and pressure. Custom molds help produce parts like cylinder heads, intake manifolds, and cooling system components.

4. Battery Housings for Electric Vehicles

Custom molds are critical in manufacturing battery housings for electric vehicles. These housings must be durable, secure, and lightweight to protect the battery.

5. Lighting Components

Custom molds can also be used for vehicle lighting components like headlights, tail lights, and indicators. These parts require intricate designs for both function and appearance.

The Benefits of Customizable Injection Molds

1. Improved Performance

Custom molds help enhance the performance of automotive parts. They are designed to meet specific functional requirements, such as durability, heat resistance, and flexibility.

2. Aesthetic Flexibility

Customization also allows for flexibility in the appearance of parts. Car manufacturers can choose colors, textures, and finishes that match their design vision.

3. Speed and Efficiency

Custom molds are designed for fast and efficient production. They help reduce cycle times, speeding up the manufacturing process.

4. Consistency and Quality

With custom molds, the quality of each part remains consistent. This is crucial for vehicle manufacturers who rely on precision in every part.

The Role of Mold Makers in the Future

1. Adapting to New Materials

As the automotive industry evolves, so do the materials used in manufacturing. A Mold Maker must be able to work with new, advanced materials, including composites, alloys, and biodegradable plastics.

2. Incorporating Smart Technology

With the rise of smart vehicles, customizable injection molds must incorporate sensors and other smart technologies. Mold Makers will need to design molds that integrate these technologies into automotive parts.

3. 3D Printing in Mold Design

3D printing will continue to play a role in custom mold creation. It allows for rapid prototyping and testing, speeding up the design process. Mold Makers will use 3D printing to create molds faster and more efficiently.

Challenges in Customizing Automotive Injection Molds

1. Complexity of Designs

Some automotive parts are highly complex. Custom molds for these parts require advanced technology and skill. The more complex the design, the more challenging it is to create the perfect mold.

2. Material Compatibility

Different materials behave differently when injected into molds. A Mold Maker must select the right material for each part, considering factors like temperature, stress, and flexibility.

3. Cost of Customization

Customization can be more expensive than standard mold production. However, the long-term benefits, such as better performance and efficiency, often outweigh the initial costs.

Customizable Automotive Injection Molds are transforming the way vehicles are manufactured. Mold Makers play a crucial role in this transformation, creating molds that are precise, efficient, and cost-effective. As the automotive industry continues to evolve, the demand for customizable molds will grow. These molds allow manufacturers to produce high-performance, durable, and aesthetically pleasing parts. The future of vehicle manufacturing is in the hands of Mold Makers and their ability to customize injection molds for the ever-changing automotive landscape.