Deisgn Guide Tips from Mold Maker

Designing a product for injection molding requires careful planning to ensure the final product is high-quality and easy to produce. Follow this guide to optimize your design, whether you’re collaborating with an injection mold company, an injection moulding factory, or a mold maker in China.

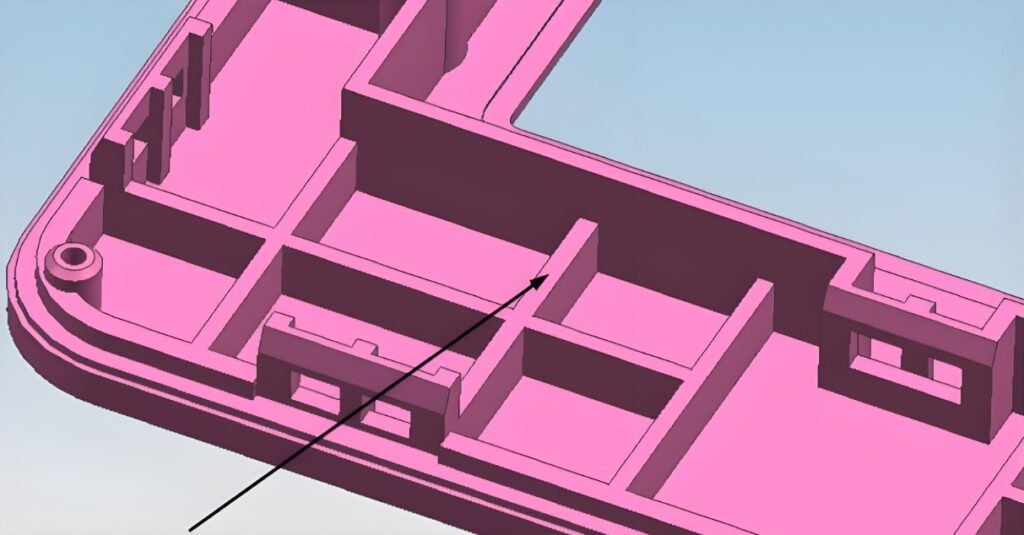

Wall Thickness:

Keep the wall thickness of your product consistent. Variations in thickness can lead to warping or uneven cooling. Uniform wall thickness simplifies the injection molding process and strengthens the final product.

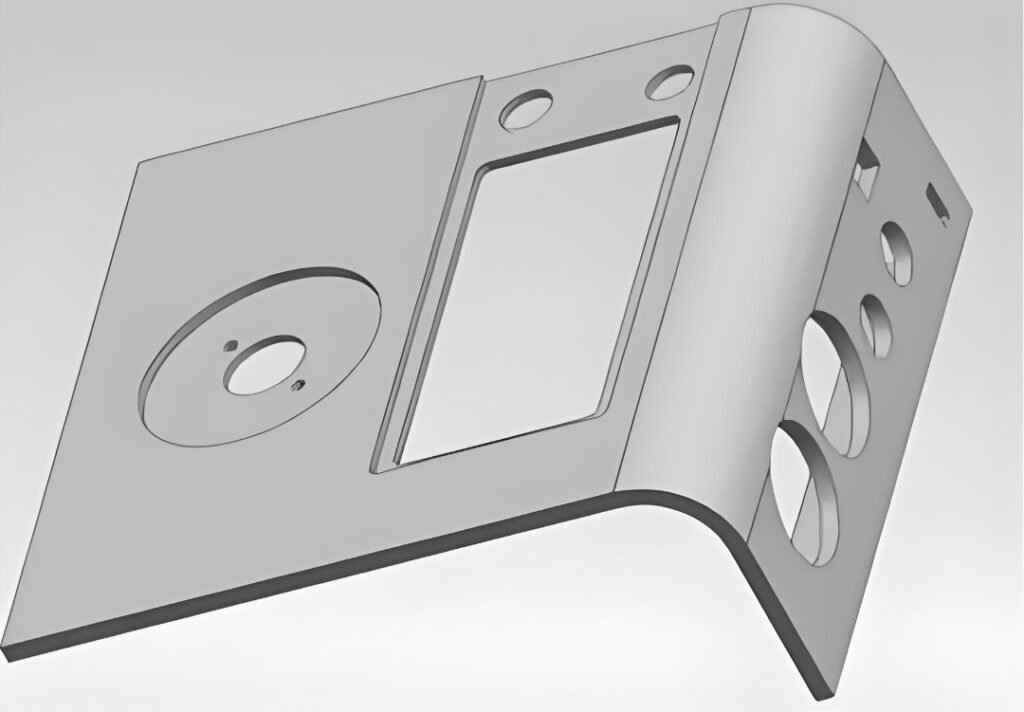

Draft Angles:

Incorporate draft angles into your design. These slight slopes on the sides of your product make it easier to remove from the mold without causing damage. Your injection moulding factory can advise on the best draft angles for your design.

Ribs and Supports:

For added strength, use ribs instead of thickening the walls. Ribs are thin, raised sections that provide support while minimizing material use and cost. They also help prevent defects during molding.

Corners and Edges:

Avoid sharp corners and edges in your design. Sharp features can create stress points and weaken the product. Rounded corners are better for the injection molding process and enhance durability.

Undercuts:

Minimize undercuts in your design. Undercuts are features that complicate the removal of the product from the mold. If undercuts are necessary, consult your injection mold company about techniques to address them.

Material Choice:

Select the right material based on your product’s needs. Whether you need strength, flexibility, or heat resistance, the mold maker in China or another factory can help you choose the appropriate material.

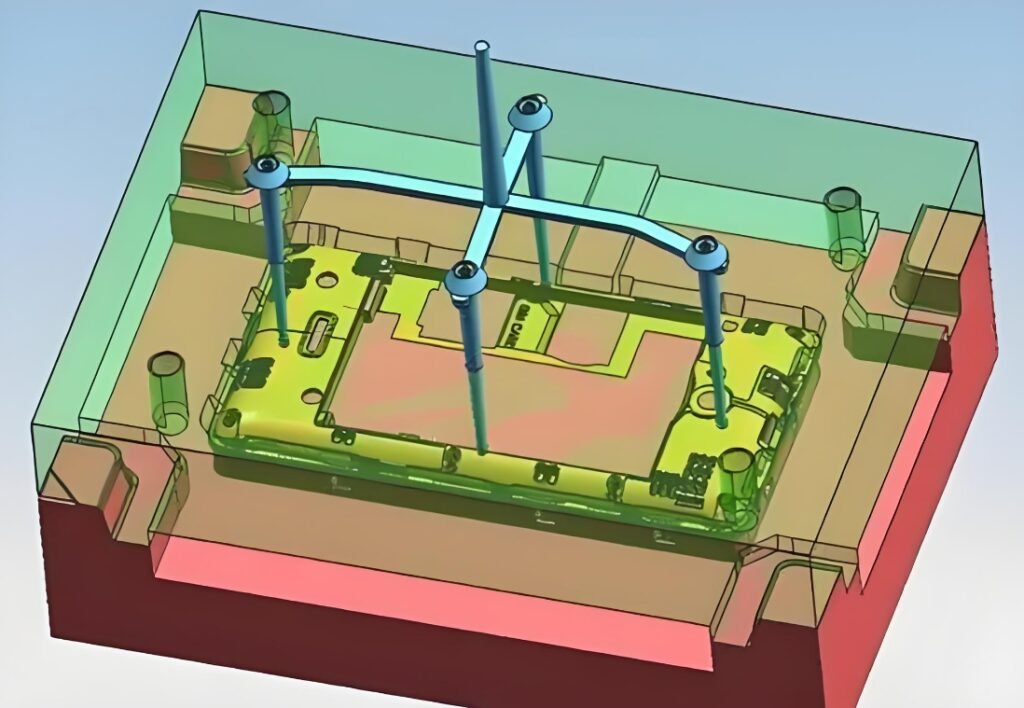

Gates and Runners:

Plan the placement of gates and runners where the material enters and flows through the mold. Proper placement ensures even filling and reduces defects.

By following this design guide, you can create a product well-suited for injection molding. Collaborating with the injection moulding factory or your mold maker ensures your design is optimized for production, leading to better quality and lower costs.