Efficiency is vital in creating Automotive Injection Molds. Skilled Mold Makers adopt advanced techniques to improve performance. Optimized processes reduce costs and improve quality. This ensures the automotive industry meets growing demands.

The Importance of Efficiency

Why It Matters

Efficient processes save time and resources. They also improve part accuracy. High efficiency ensures molds deliver consistent results.

Role of Mold Makers

A professional Mold Maker focuses on streamlining workflows. Their expertise leads to better productivity.

Key Steps in the Injection Mold Process

1. Design and Planning

The process starts with detailed designs. CAD tools create precise mold models. Early planning identifies potential issues.

2. Material Selection

The right materials ensure durability. Steel and aluminum are common. Lightweight materials reduce production times.

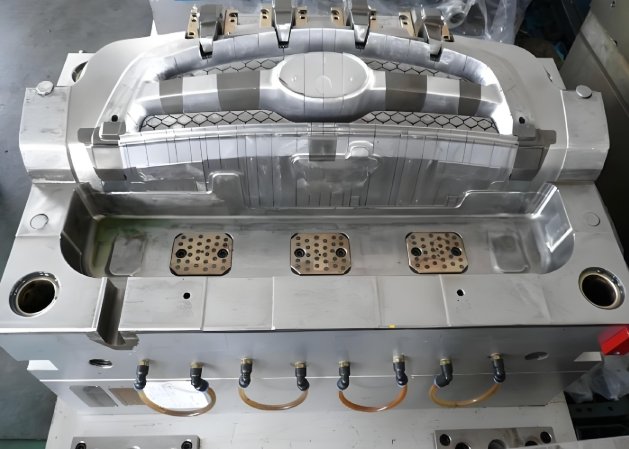

3. Tool Manufacturing

CNC machines cut molds with precision. This step defines the mold’s quality. Mold Makers ensure accuracy here.

4. Testing and Prototyping

Prototypes verify mold designs. Adjustments refine the product for mass production.

Innovations in Efficiency

1. Advanced Cooling Systems

Cooling systems reduce cycle times. Faster cooling means more parts produced.

2. Automation and Robotics

Automation speeds up production. Robots ensure consistent output. These tools minimize errors.

3. Smart Sensors

Sensors monitor temperature and pressure. This helps maintain optimal performance.

4. 3D Printing for Prototypes

3D printing allows quick prototyping. It reduces lead times significantly.

Challenges in Achieving Efficiency

1. High Initial Costs

Advanced tools require significant investment. However, the long-term savings justify it.

2. Material Compatibility

Not all materials work with every design. Selecting the right one is crucial.

3. Skilled Workforce

A trained team is essential. Efficient processes rely on expert Mold Makers.

Benefits of Optimized Processes

1. Faster Production

Shorter cycle times improve output. This helps meet tight deadlines.

2. Improved Quality

Accurate molds produce flawless parts. Better quality enhances customer satisfaction.

3. Cost Savings

Optimized processes reduce waste. This lowers overall production costs.

Role of Mold Makers in Efficiency

1. Expert Craftsmanship

Mold Makers ensure precise designs. Their expertise minimizes errors.

2. Innovative Thinking

They adopt the latest trends. This includes AI, automation, and advanced materials.

3. Continuous Improvement

A skilled Mold Maker constantly refines processes. This keeps production efficient.

Trends Boosting Efficiency

1. Eco-Friendly Practices

Sustainable methods reduce waste. Recyclable materials are now common.

2. Lightweight Designs

Lighter molds improve handling. They also speed up manufacturing.

3. Digital Twins

Digital twins simulate mold performance. This allows pre-production adjustments.

Application in Automotive Manufacturing

1. Interior Parts

Dashboards and door panels require precise molds. Efficient processes ensure a perfect fit.

2. Engine Components

Durable molds create functional engine parts. Quality is crucial for safety.

3. Lightweight Structures

Modern cars need lighter parts. Automotive Injection Molds support this demand.

Future of Efficiency

1. AI Integration

AI will optimize designs further. This will reduce development times.

2. Energy-Efficient Machines

New machines consume less power. They also produce consistent results.

3. Personalization

Customized molds will become more common. This meets specific automotive needs.

Why Choose the Right Mold Maker

1. Precision

A good Mold Maker ensures flawless molds. This reduces defects.

2. Reliability

Expert Mold Makers deliver on time. They also provide ongoing support.

3. Cost-Effectiveness

Efficient processes lower production costs. Skilled Mold Makers achieve this balance.

Efficiency drives the success of Automotive Injection Molds. Skilled Mold Makers play a key role in achieving it. Advanced processes and technologies ensure faster, better, and cheaper production.

Investing in efficiency benefits the entire automotive supply chain. Choose an expert Mold Maker to meet your manufacturing goals.