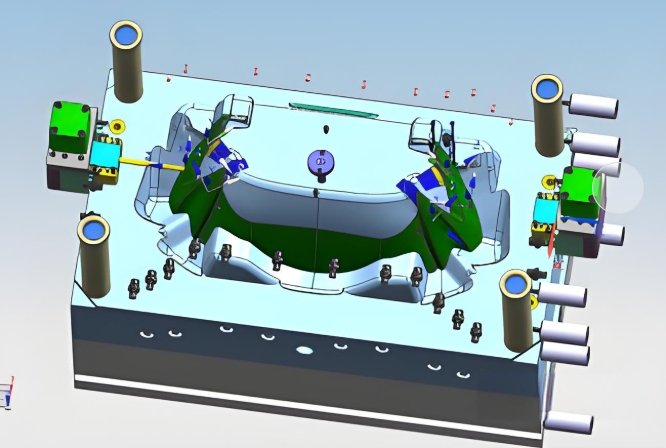

Precision matters in automotive manufacturing. Automotive injection molds shape vital car parts. A skilled mold maker ensures accuracy, durability, and efficiency. Advanced molding techniques improve quality and consistency.

Why Consistency Matters in Automotive Molding

1. Safety and Performance

Automotive parts must meet strict safety rules. Automotive injection molds ensure accurate dimensions. A mold maker prevents defects.

2. Cost Control

Waste increases expenses. Automotive injection molds reduce errors. A mold maker optimizes material use.

3. Uniform Fit and Assembly

Every car part must fit perfectly. Automotive injection molds ensure identical components. A mold maker maintains precision.

Key Mold Processes for Consistent Parts

1. High-Precision CNC Machining

Machines cut with extreme accuracy. Automotive injection molds require precise shaping. A mold maker ensures flawless results.

2. Electrical Discharge Machining (EDM)

Complex shapes need special techniques. Automotive injection molds use EDM for intricate details. A mold maker controls precision.

3. Automated Injection Molding Machines

Manual errors slow production. Automotive injection molds run on automated systems. A mold maker programs machines for efficiency.

4. Hot Runner Systems for Material Flow

Better flow means fewer defects. Automotive injection molds with hot runners reduce waste. A mold maker optimizes temperature control.

5. Real-Time Monitoring for Quality Control

Sensors detect problems instantly. Automotive injection molds with real-time monitoring improve consistency. A mold maker corrects errors fast.

Common Automotive Plastic Components

1. Engine Covers

Heat resistance is critical. Automotive injection molds create durable engine covers. A mold maker selects strong materials.

2. Interior Trim Panels

Perfect finishes matter. Automotive injection molds shape seamless trim panels. A mold maker ensures smooth surfaces.

3. Bumper Components

Impact resistance is key. Automotive injection molds produce tough bumpers. A mold maker enhances durability.

4. Air Intake Systems

Precision ensures performance. Automotive injection molds form complex air ducts. A mold maker prevents airflow restrictions.

5. Lighting Housings

Clarity and protection matter. Automotive injection molds create strong light covers. A mold maker ensures transparency.

Advanced Materials for Automotive Injection Molds

1. High-Strength Thermoplastics

Durability is essential. Automotive injection molds use reinforced thermoplastics. A mold maker selects tough polymers.

2. Polycarbonate for Optical Clarity

Lights need clear casings. Automotive injection molds use polycarbonate for lenses. A mold maker ensures high visibility.

3. Nylon for Heat Resistance

Engine parts require strong materials. Automotive injection molds use nylon composites. A mold maker enhances thermal stability.

4. ABS for Impact Resistance

Crashes demand strong bumpers. Automotive injection molds use ABS plastics. A mold maker reinforces safety.

Techniques to Improve Mold Efficiency

1. Conformal Cooling Channels

Better cooling speeds up cycles. Automotive injection molds use advanced cooling designs. A mold maker reduces production time.

2. Gas-Assisted Injection Molding

Lighter parts perform better. Automotive injection molds with gas assistance create hollow sections. A mold maker ensures strength.

3. Two-Shot Molding for Multi-Layer Parts

Some parts need dual materials. Automotive injection molds use two-shot techniques. A mold maker enhances bonding.

4. Mold Flow Analysis for Defect Prevention

Software predicts issues before molding. Automotive injection molds use simulations for accuracy. A mold maker prevents warping.

Automation in Injection Mold Manufacturing

1. Robotic Part Handling

Automation speeds up work. Automotive injection molds integrate robotic systems. A mold maker ensures smooth operations.

2. AI-Based Quality Control

AI detects microscopic defects. Automotive injection molds use smart inspections. A mold maker enhances precision.

3. Smart Injection Molding Machines

Self-adjusting machines improve efficiency. Automotive injection molds run on adaptive settings. A mold maker fine-tunes parameters.

Sustainability in Automotive Injection Molding

1. Recycled Plastic Use

Green materials matter. Automotive injection molds now use recycled resins. A mold maker minimizes waste.

2. Energy-Efficient Mold Systems

Lower energy use reduces costs. Automotive injection molds work with eco-friendly machines. A mold maker optimizes processes.

3. Scrap Reduction Strategies

Less waste means more profit. Automotive injection molds eliminate excess plastic. A mold maker ensures lean production.

4. Bio-Based Plastics for Future Vehicles

Sustainability is the future. Automotive injection molds adapt to bio-plastics. A mold maker follows industry trends.

Challenges in Automotive Injection Molding

1. Heat Management in High-Stress Parts

Extreme temperatures affect parts. Automotive injection molds must handle heat. A mold maker selects durable materials.

2. Complex Aerodynamic Designs

Car bodies need smooth edges. Automotive injection molds shape precise curves. A mold maker ensures aerodynamic efficiency.

3. Cost Control in Mass Production

Efficiency saves money. Automotive injection molds must work faster. A mold maker balances speed and quality.

4. Faster Cycle Times for Higher Output

Quick production boosts profits. Automotive injection molds need optimized cooling and fast ejection. A mold maker refines every detail.

Future Trends in Automotive Injection Molds

1. 3D-Printed Prototypes for Faster Development

Testing saves time. Automotive injection molds use rapid prototyping. A mold maker validates designs quickly.

2. AI-Driven Mold Design Optimization

Smarter technology improves results. Automotive injection molds now use AI simulations. A mold maker enhances precision.

3. Lightweight Materials for Electric Vehicles

EVs need weight reduction. Automotive injection molds create lighter components. A mold maker optimizes plastic selection.

4. Smart Plastics for Connected Vehicles

New materials integrate sensors. Automotive injection molds now shape high-tech parts. A mold maker innovates for future needs.

Efficient automotive injection molds improve part consistency. A skilled mold maker ensures accuracy, strength, and cost savings. The future of automotive molding focuses on automation, sustainability, and precision.