In today’s fast-paced manufacturing world, efficiency is key. Every business strives to improve its production processes. One of the most important steps is ensuring your production line runs smoothly. An injection mould company plays a crucial role in making sure your injection molding process is efficient. The right mold maker and high-quality injection molds can help streamline your operations and increase output.

Injection molding is a method used to create parts by injecting molten material into a mold. This process is used in various industries, including automotive, electronics, medical devices, and consumer products. However, without the right molds, injection molding can become inefficient, leading to delays, defects, and wasted materials. That’s where an expert injection mould company comes in.

A professional mold maker can create injection molds that are designed to perform consistently, allowing you to produce high-quality parts at a faster rate. When you work with a reliable injection mould company, you are ensuring that your molds are of the highest quality. These molds are crucial for achieving efficiency in your production lines.

The Importance of High-Quality Injection Molds

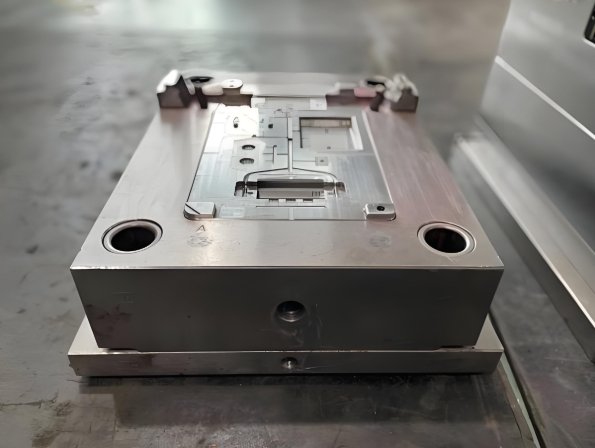

The heart of any injection molding process is the mold. A mold is a tool used to shape molten material into a specific form. Injection molds come in various designs, depending on the part being produced. These molds must be precise, durable, and able to withstand the high pressure and temperature of the injection process.

A poor-quality mold can lead to several problems. The material may not fill the mold correctly, leading to defects in the final product. If the mold wears out too quickly, you’ll need to replace it more often, causing downtime in production. A high-quality mold, however, will produce consistent results over time, helping to maintain a smooth and efficient production line.

A skilled mold maker understands the intricacies of creating molds that are both durable and precise. They consider the material being used, the complexity of the part, and the specific requirements of the production line. The injection mould company you choose should have experience designing and producing molds that meet these requirements.

How an Injection Mould Company Boosts Efficiency

An experienced injection mould company brings several benefits that can improve the efficiency of your production line. The right mold maker ensures that molds are designed for quick production runs, reducing cycle times. Here’s how an expert injection mould company can help:

- Precision and Consistency: A skilled mold maker designs molds with high precision. This ensures that each part is made to exact specifications. Consistent results lead to fewer rejections and less waste, improving overall efficiency.

- Faster Cycle Times: High-quality injection molds are designed to fill and cool quickly. This reduces the time it takes to complete a production cycle. The faster you can produce parts, the higher your output will be.

- Reduced Downtime: Quality molds last longer. This means less time spent on repairs or mold replacements. When molds are well-maintained, production lines experience less downtime, which leads to higher efficiency.

- Lower Production Costs: With the right injection molding equipment and molds, you can reduce material waste and improve throughput. This results in lower overall production costs, making your manufacturing process more cost-effective.

- Higher-Quality Products: High-quality molds lead to high-quality parts. A reliable injection mould company ensures that the molds they provide are durable and precise. This results in fewer defects and more consistent products, which is essential for maintaining efficiency in your production line.

Working with a Professional Mold Maker

A mold maker is a skilled professional who designs and creates molds for the injection molding process. They use their expertise to ensure that the molds are made to high standards and that they will perform well in the production environment.

The process starts with the design phase. The mold maker works with you to understand the product requirements and the materials to be used. They then design the mold to fit those specifications. Once the design is approved, the mold is manufactured, tested, and refined to ensure it performs efficiently during the injection molding process.

The experience of the mold maker is crucial to creating molds that can withstand the pressure of injection molding. They must design molds that can handle high temperatures, pressure, and the material used in the process. Inexperienced mold makers may create molds that wear out too quickly or do not fill properly, leading to inefficiencies and defects in production.

The Role of an Injection Mould Company in Your Production Line

An injection mould company is responsible for providing the molds needed for the injection molding process. However, their role goes beyond just supplying molds. They offer support throughout the production process. Here’s how:

- Design and Engineering: The injection mould company helps design molds that meet your specific needs. They ensure that the molds are compatible with your materials and production methods.

- Prototyping: Many injection mould companies offer prototyping services. This allows you to test the mold and make adjustments before full-scale production begins.

- Manufacturing and Testing: The injection mould company manufactures the molds and tests them to ensure they perform properly in the injection molding process. They may perform trial runs to check for any defects or inconsistencies.

- Maintenance and Support: Even after the molds are in use, the injection mould company provides ongoing support. They offer maintenance services to ensure the molds continue to perform well and that your production line stays efficient.

The Impact of Efficient Production Lines

Efficiency is crucial in any manufacturing operation. The more efficient your production line, the higher your output, and the lower your costs. By working with an expert injection mould company, you are setting your production line up for success.

Efficient injection molding results in less waste, fewer defects, and faster production cycles. This leads to cost savings, higher product quality, and better overall performance. Whether you are producing a small batch or mass-producing parts, efficiency is key to meeting deadlines and staying competitive in the market.

An expert injection mould company can make a significant difference in the efficiency of your production line. By working with a skilled mold maker and using high-quality injection molds, you can streamline your injection molding process, reduce costs, and increase production speed. The right molds ensure that your production runs smoothly, consistently, and efficiently. In turn, this leads to higher-quality products and a more successful business operation.