The Challenge: Delays in Product Launch

An electronics company was developing a new product. However, they were facing delays in getting the product to market. The delays were caused by issues with the existing molds used for their plastic components. These injection molds were outdated and could not keep up with the demand for faster production.

The company needed a solution quickly. They turned to an injection mould company that specialized in designing and creating custom molds. The mold maker had a strong reputation for solving complex problems and speeding up production timelines.

Analyzing the Problem

The mold maker began by evaluating the existing injection molds. They found several issues that were slowing down production. First, the molds had a complicated design that led to longer cycle times during the injection molding process. Each mold required a lengthy cooling period, which caused delays.

Second, the molds were not optimized for automation. This meant that the company had to rely on manual processes for part of the production, which added to the time and cost.

The mold maker knew that to help the electronics company reduce time to market, they would need to develop new injection molds that were faster, more efficient, and fully compatible with automated processes.

Designing Faster Injection Molds

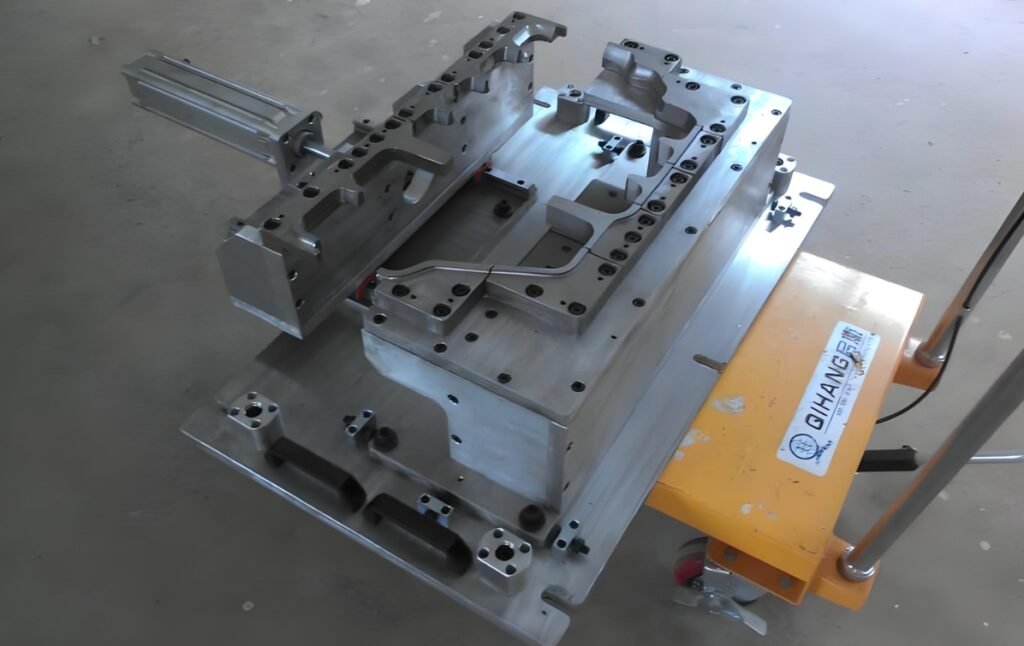

The mold maker’s first step was to redesign the injection molds. They focused on reducing the cycle time for each part. This meant creating molds with optimized cooling channels, allowing the plastic parts to cool faster without compromising quality.

By using computer-aided design (CAD) software, the mold maker was able to simulate the flow of plastic into the mold and identify areas where they could improve efficiency. The result was a set of new injection molds that could produce parts faster and with fewer defects.

Implementing Automation

To further speed up production, the mold maker integrated the new injection molds with automated systems. This allowed the electronics company to produce more parts without needing manual intervention. The injection molding process could now run continuously, reducing downtime between cycles.

Automation also improved consistency in the parts being produced. The new injection molds were designed to work seamlessly with robotic systems that handled part removal, inspection, and packaging. This increased the overall speed of production while ensuring high-quality standards were maintained.

Using High-Quality Materials

The mold maker also chose high-quality materials for the new injection molds. This was important for maintaining the durability of the molds during high-volume production. The use of hardened steel ensured that the injection molds would last longer and require less maintenance, which contributed to the reduced time to market.

Additionally, the materials used in the mold cavities were selected to allow for faster cooling. This was key to reducing cycle times and increasing the number of parts that could be produced per hour.

Testing and Validation

Before the new injection molds were put into full-scale production, the mold maker conducted extensive testing. They ran several production trials to ensure that the molds would meet the company’s requirements for speed and quality.

The testing phase was crucial for identifying any potential issues with the new molds. The mold maker worked closely with the electronics company to make any necessary adjustments. Once testing was complete, the company was confident that the new injection molds would help them meet their production goals.

Reducing Time to Market

With the new injection molds in place, the electronics company saw an immediate improvement in their production process. The cycle time for each part was significantly reduced, allowing them to produce more parts in less time. The integration of automation further accelerated production by eliminating manual processes.

As a result, the company was able to reduce its time to market by several weeks. This allowed them to launch their new product ahead of schedule, giving them a competitive advantage in the market. The faster production also helped them meet customer demand more efficiently.

The Long-Term Benefits

The improvements made by the mold maker didn’t just benefit the electronics company for one product launch. The new injection molds were designed for long-term use, meaning the company could continue to use them for future products.

By investing in high-quality injection molds and automation, the electronics company was able to improve its overall manufacturing capabilities. This made it easier for them to develop and launch new products quickly, without facing the same delays they had encountered before.

The mold maker’s role in this success highlights the importance of working with an experienced injection mould company. A skilled mold maker can help businesses overcome production challenges and reduce time to market, giving them a significant edge over competitors.

In this case study, a mold maker played a critical role in helping an electronics company reduce its time to market. By redesigning injection molds to reduce cycle times, integrating automation, and using high-quality materials, the mold maker was able to significantly speed up production. This allowed the company to launch their new product ahead of schedule and improve their overall manufacturing process.

For any company looking to reduce time to market, working with an expert mold maker is essential. The right injection molds can make all the difference in achieving faster production, higher quality, and greater efficiency.