Delays in production can cost companies a lot of money. They slow down product launches and can hurt a business’s reputation. One company was facing serious delays in their production line due to problems with their injection molds. But a skilled mold maker stepped in and saved the project. This is the story of how a mold maker prevented a disaster and ensured the project’s success.

The Challenge: Faulty Injection Molds

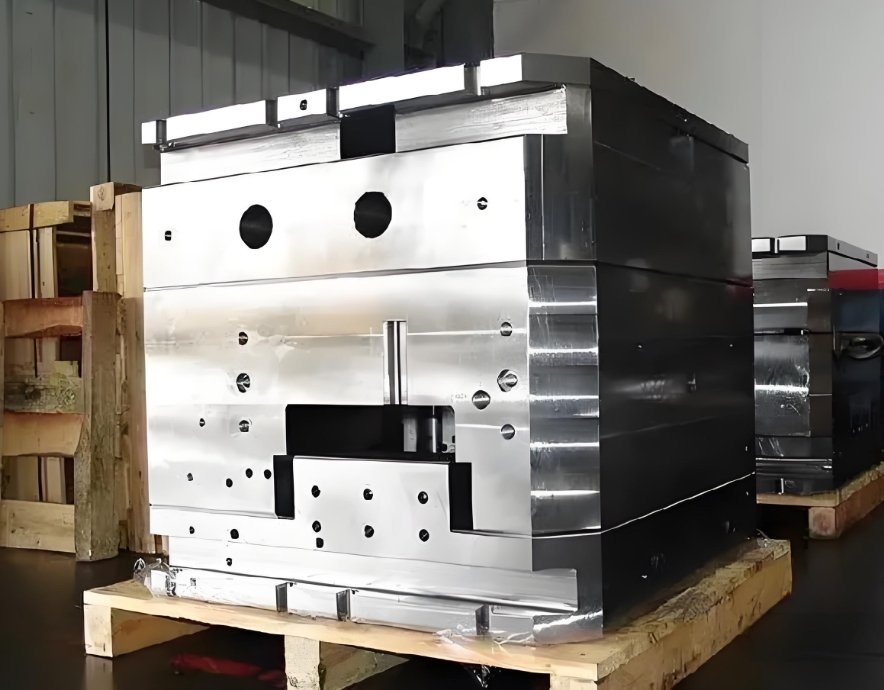

The project involved creating custom plastic parts through injection molding. The injection molds being used were not performing as expected. There were multiple issues. Some molds produced defective parts, while others slowed down production due to long cycle times. The injection mould company in charge was concerned that the molds would fail entirely.

These problems created delays, and the company was losing money every day the project was behind schedule. The management team decided to bring in an experienced mold maker to assess the situation.

Assessing the Situation

The mold maker arrived on-site and immediately started reviewing the existing injection molds. He noticed a few key problems right away. The molds had been designed poorly and were not optimized for fast cycle times. Some molds were worn out and needed repair. Others had not been properly maintained, leading to defects in the parts they produced.

The mold maker understood that solving these problems would be challenging. However, he was confident that he could make the necessary improvements and save the project from further delays.

Fixing the Molds

The first step was repairing the worn-out injection molds. The mold maker replaced damaged parts and reinforced weak areas. He also made adjustments to the molds to improve their durability. This allowed the molds to perform better under high pressure, which is essential in injection molding.

Next, the mold maker worked on optimizing the cycle times. He redesigned parts of the molds to allow the molten plastic to flow more easily, speeding up the production process. This change significantly reduced the time it took to create each part.

Preventing Future Issues

The mold maker didn’t just focus on fixing the current problems. He also wanted to ensure that the injection mould company would not face similar issues in the future. He introduced new maintenance procedures to keep the injection molds in good condition. These included regular inspections and lubrication to prevent wear and tear.

The mold maker also recommended that the company invest in higher-quality materials for their molds. This would help them last longer and reduce the need for frequent repairs. By preventing future issues, the mold maker ensured the company wouldn’t face costly delays down the line.

Improving Communication with the Injection Mould Company

One of the major issues the company faced was a lack of communication with their original mold supplier. The mold maker addressed this by improving communication between the company and the injection mould company. He made sure that the injection mould company understood the specific needs of the project and worked closely with them to ensure those needs were met.

Better communication helped the company avoid misunderstandings and allowed them to get the right injection molds on time. It also ensured that any future problems would be identified early and addressed before they became serious.

Results: Project Back on Track

Thanks to the mold maker’s efforts, the project was back on track. The injection molds were performing better than ever, with faster cycle times and fewer defects. The company was able to catch up on production and meet their deadlines. They also saved a significant amount of money by avoiding further delays.

The mold maker’s expertise not only fixed the immediate problems but also improved the overall efficiency of the company’s production process. This helped them meet their customer’s demands and avoid financial losses.

The Importance of a Skilled Mold Maker

This story highlights the importance of having a skilled mold maker on your team. A mold maker is not just responsible for designing and creating injection molds. They also play a key role in maintaining and optimizing molds to ensure that production runs smoothly.

In this case, the mold maker saved the company from costly delays by identifying and fixing problems with their injection molds. His knowledge of the injection molding process allowed him to make changes that significantly improved efficiency and product quality.

Without the mold maker’s intervention, the company might have faced even more delays, higher costs, and unhappy customers. Instead, they were able to deliver high-quality products on time and keep their customers satisfied.

Conclusion: Mold Makers Are Critical to Success

Injection molding is a complex process that requires high-quality molds. When things go wrong, the consequences can be costly. That’s why having an experienced mold maker on your team is so important. A mold maker can quickly identify problems with injection molds, make necessary repairs, and ensure that production runs smoothly.

In this case, a mold maker saved a project from costly delays by fixing faulty molds and optimizing the production process. His work not only got the project back on track but also improved the company’s long-term production efficiency.

For any injection mould company, having a reliable mold maker is essential. They ensure that molds are built to last and perform well under pressure. With the right mold maker, companies can avoid costly delays and deliver high-quality products on time.