In today’s competitive market, businesses constantly seek ways to create high-quality products quickly and cost-effectively. One of the most important processes in product development is injection molding. An injection mould company plays a vital role in supporting businesses by providing the necessary tools and expertise to produce efficient, functional, and durable products.

In this article, we will explore how an injection mould company supports product development, focusing on the roles of mold makers, injection molds, and the injection molding process.

The Role of Injection Molding in Product Development

Injection molding is a manufacturing process used to produce parts in large volumes. It involves injecting molten material into a mold cavity. The material then cools and solidifies to form the desired shape. The process is highly versatile, making it ideal for producing everything from small components to large, complex products.

The benefits of injection molding in product development are numerous:

- Efficiency: It allows for fast production at low cost, especially for high-volume runs.

- Precision: The process can create very detailed and precise shapes, ensuring high-quality products.

- Material Variety: It can use a wide range of materials, including plastics, metals, and composites, to suit different product needs.

How an Injection Mould Company Supports Businesses

An injection mould company plays an essential role in helping businesses take their product ideas from concept to reality. Here’s how they contribute to the product development process:

1. Design and Prototyping

The product development journey begins with design. Once a business has an idea for a new product, an injection mould company collaborates with engineers and designers to create an optimal design for injection molding. This involves considering factors like material selection, product geometry, and mold structure.

Many injection mould companies also offer prototyping services, which allow businesses to test their designs before committing to full-scale production. Rapid prototyping helps to verify the functionality and aesthetics of the product early on, saving time and money.

2. Expertise in Mold Making

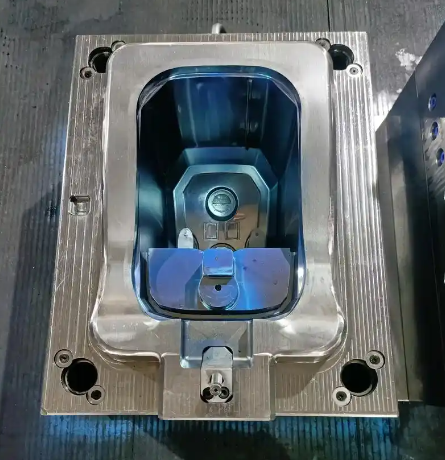

One of the most critical roles of an injection mould company is mold making. A mold is essentially the blueprint for the final product. Without a well-designed and precisely manufactured mold, the injection molding process cannot produce high-quality results.

Mold makers at an injection mould company are experts in creating custom molds that meet the specific requirements of the product. They consider factors such as:

- Mold durability: Molds must be strong and capable of withstanding high pressures and temperatures during production.

- Mold complexity: Complex parts may require multi-part molds, which require advanced design and manufacturing techniques.

- Mold cooling: Efficient cooling channels are essential to prevent warping and to speed up production cycles.

By working with skilled mold makers, businesses can ensure that the molds used in injection molding are designed to meet the highest standards and produce the best possible products.

3. Selection of Materials

Material selection is a critical aspect of the injection molding process. The choice of material depends on the product’s intended use, durability requirements, and aesthetic preferences. An injection mould company helps businesses select the right material for the job by considering:

- Strength and flexibility: Some products require tough, durable materials, while others need more flexibility.

- Cost-effectiveness: The right material can help reduce production costs without sacrificing quality.

- Environmental impact: Many businesses today are focused on sustainability. Injection mould companies can offer eco-friendly material options, such as biodegradable plastics, for companies looking to reduce their environmental footprint.

4. Optimizing the Injection Molding Process

Once the design and molds are finalized, an injection mould company helps optimize the injection molding process for efficiency, speed, and cost-effectiveness. This includes:

- Setting up the production line: The injection molding machines must be properly set up to ensure consistency in each product.

- Testing and quality control: Continuous testing is done to monitor the quality of each part, ensuring that it meets specifications.

- Troubleshooting: If any issues arise during production, such as defects in the parts, the injection mould company quickly identifies and addresses the problem.

By fine-tuning the injection molding process, the company ensures that the final product is produced at the highest possible quality while minimizing waste and downtime.

5. Cost-Effective Production

An injection mould company can help businesses reduce production costs in several ways:

- High-volume production: Once the mold is created, the injection molding process can produce thousands or even millions of parts with minimal labor and material costs.

- Fast turnaround times: The quick cycle times of injection molding mean that products can be produced in a fraction of the time it would take using other manufacturing methods.

- Reduced waste: With the right mold design, the injection molding process is highly efficient, with little material waste, further reducing costs.

By offering these cost-saving benefits, an injection mould company helps businesses stay competitive in the marketplace.

Ensuring High-Quality Products

Quality is a top priority for any injection mould company. The company ensures that the products meet or exceed industry standards by:

- Using advanced technology: State-of-the-art machinery and equipment are essential for producing high-quality molds and parts.

- Implementing quality control systems: Every step of the production process, from mold making to final product inspection, is closely monitored to ensure consistent quality.

- Testing prototypes: Before mass production begins, prototypes are thoroughly tested to identify any issues.

By maintaining strict quality control throughout the production process, an injection mould company guarantees that businesses receive products that meet their expectations.

Conclusion

An injection mould company plays a crucial role in supporting businesses during product development. From the initial design and prototyping to the production of high-quality molds and efficient injection molding, the company provides the expertise and resources needed to bring products to market quickly and affordably.

Through expert mold makers, precise material selection, process optimization, and cost-effective production methods, an injection mould company helps businesses turn their ideas into successful, market-ready products. Whether you’re developing consumer goods, automotive parts, or medical devices, working with an experienced injection mould company can make all the difference in your product’s success.