Modern cars need precision. Every part must fit perfectly. Automotive injection molds create these parts. A skilled mold maker ensures accuracy. High-quality molds improve strength and design. Lightweight components boost efficiency. Injection molding shapes the future of vehicles.

Why Injection Molding is Key in Automotive Design

1. Precision Manufacturing

Molds create exact parts. Consistency is guaranteed.

2. Lightweight Construction

Plastic components reduce weight. Fuel efficiency improves.

3. High Durability

Injection-molded plastics resist wear. They last longer.

4. Mass Production Efficiency

Thousands of parts are produced quickly. Costs remain low.

5. Complex Design Capabilities

Molds create intricate shapes. Customization increases.

Essential Automotive Parts Made with Injection Molds

1. Dashboard Panels

Molds ensure perfect fit. Heat resistance improves durability.

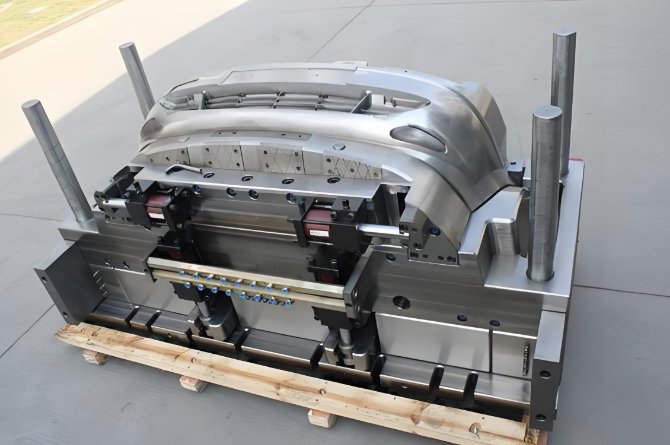

2. Bumper Covers

Injection-molded bumpers absorb impact. Weight is reduced.

3. Door Panels

Seamless designs enhance aesthetics. Custom textures are possible.

4. Grilles and Air Vents

Durable plastics improve airflow. Vehicle efficiency increases.

5. Headlight and Taillight Housings

Transparent plastics improve lighting. Molds ensure precise alignment.

6. Center Consoles

Scratch-resistant surfaces improve lifespan. Lightweight materials enhance comfort.

7. Under-the-Hood Components

Heat-resistant plastics handle extreme temperatures. Strength ensures reliability.

8. Seating Components

Injection-molded supports add comfort. Weight reduction improves performance.

The Role of a Mold Maker in Automotive Injection Molds

1. Advanced Mold Design

Engineers create precise molds. Accuracy improves quality.

2. High-Quality Mold Materials

Strong metals extend mold lifespan. Maintenance costs decrease.

3. CNC Machining for Precision

Computerized cutting ensures perfection. Every cavity is flawless.

4. Efficient Cooling Systems

Cooling reduces cycle times. Production speeds increase.

5. Rigorous Quality Control

Each mold undergoes inspection. Flaws are eliminated.

Injection Molding Process in Automotive Manufacturing

1. Material Selection

Choosing the right plastic affects performance. Heat resistance matters.

2. Mold Fabrication

A skilled mold maker builds precise tools. Every detail is perfected.

3. Injection and Cooling

Molten plastic fills molds. Cooling solidifies parts.

4. Ejection and Finishing

Parts are removed. Surface finishing enhances appearance.

5. Quality Inspection

Strict tests ensure durability. Flaws are corrected.

Advantages of Automotive Injection Molds

1. Cost-Effective Production

Mass production lowers expenses. Waste is minimized.

2. Stronger, Safer Components

Injection-molded plastics absorb impact. Safety improves.

3. Faster Manufacturing Speeds

Automation speeds up molding. Lead times decrease.

4. Environmentally Friendly Materials

Recycled plastics reduce waste. Sustainability increases.

5. Customization Options

Various textures and colors are available. Designs become unique.

Innovations in Automotive Injection Molds

1. Multi-Material Molding

Combining materials enhances strength. Performance improves.

2. Smart Mold Technology

Sensors monitor molding conditions. Defects decrease.

3. Gas-Assisted Molding

Hollow sections reduce weight. Strength remains high.

4. 3D Printing for Prototyping

Faster mold development saves time. Testing improves efficiency.

5. Advanced Surface Coatings

Wear-resistant coatings extend mold life. Maintenance costs drop.

Challenges in Automotive Injection Molding

1. Shrinkage Issues

Materials shrink during cooling. Precision adjustments fix this.

2. Heat Resistance

High temperatures require strong plastics. Special formulations help.

3. Surface Defects

Scratches and blemishes reduce quality. Advanced finishing improves appearance.

4. Meeting Industry Standards

Automotive parts must meet strict regulations. Accuracy is essential.

5. Speed vs. Quality

Faster production must not sacrifice precision. Advanced cooling systems help.

Future of Automotive Injection Molds

1. Lightweight, Stronger Materials

New plastics improve efficiency. Vehicle weight drops.

2. Smart, Integrated Components

Molded parts house electronics. Functionality increases.

3. Sustainable Manufacturing

Recycled plastics become common. Green production expands.

4. Advanced Customization

More colors, patterns, and finishes emerge. Personalization increases.

5. Safety Enhancements

Better materials improve crash protection. Passenger safety strengthens.

Automotive injection molds create precise, lightweight, and durable parts. A skilled mold maker ensures accuracy. Modern vehicles rely on high-quality molds. Innovation in molding technology drives the future of automotive design.