Lightweight parts are in demand. They are essential in industries like automotive, aerospace, and electronics. Designing such parts requires expertise. This is where an Injection Mould Company plays a vital role.

Using Injection Molding, these companies deliver lightweight parts with strength and precision. They help reduce weight while maintaining durability.

What Is Injection Molding?

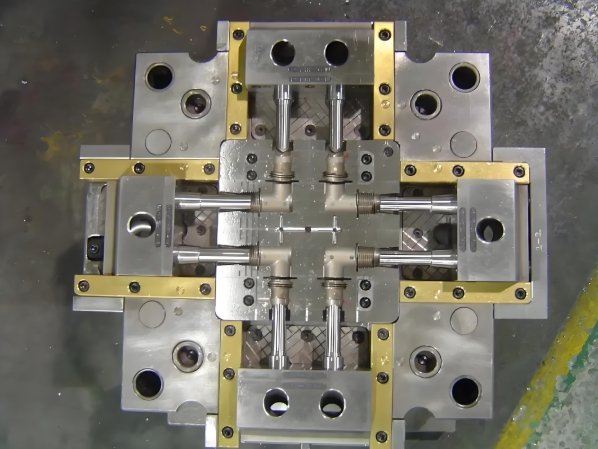

Injection Molding is a manufacturing process. It uses molds to create parts. Materials like plastic or composites are injected into molds.

The process ensures:

- High precision.

- Uniformity in production.

- Minimal material waste.

For lightweight parts, Injection Molding is ideal. It produces strong yet lightweight components.

How Mold Makers Enable Lightweight Designs

A Mold Maker is key to lightweight design. They create molds tailored for specific parts. Their designs are optimized for reduced weight.

Mold Makers ensure:

- Minimal material use.

- Strong and durable mold designs.

- Custom solutions for unique part needs.

With skilled Mold Makers, lightweight parts meet strict quality standards.

Advantages of Injection Molding for Lightweight Parts

Lightweight parts offer many benefits. Injection Molding enhances these advantages.

Key benefits include:

- Cost Efficiency: Less material means lower costs.

- Energy Savings: Lightweight parts improve energy efficiency in vehicles and machinery.

- Customization: Molds can be tailored for specific designs.

- High Strength-to-Weight Ratio: Parts remain durable despite reduced weight.

Industries That Benefit

Lightweight parts are used in many sectors. Injection Mould Companies support industries such as:

- Automotive: Fuel-efficient vehicles need lightweight components.

- Aerospace: Lightweight parts improve flight efficiency.

- Electronics: Compact devices require lightweight casings and components.

- Medical: Lightweight tools enhance usability.

Each industry has unique needs. A professional Injection Mould Company delivers customized solutions.

Material Selection for Lightweight Parts

Choosing the right material is crucial. Injection Molding supports a variety of materials. These include:

- Lightweight plastics.

- Composite materials.

- High-strength polymers.

An experienced Injection Mould Company helps select the best material. This ensures parts are both light and durable.

Design Techniques for Lightweight Parts

Design plays a major role in reducing weight. Injection Molding allows advanced design techniques like:

- Thin-Wall Molding: Reducing thickness without sacrificing strength.

- Ribbed Structures: Adding strength while using less material.

- Hollow Designs: Removing unnecessary material for weight reduction.

Skilled Mold Makers create molds for these techniques. The result is lightweight, efficient parts.

Sustainability in Lightweight Design

Sustainability is a priority. Lightweight parts reduce energy consumption. Using recyclable materials supports eco-friendly practices.

An Injection Mould Company ensures sustainable production. They minimize waste and use energy-efficient processes.

How an Injection Mould Company Ensures Success

Partnering with a reliable Injection Mould Company has many benefits. Their expertise in Injection Molding ensures high-quality results.

Advantages of working with professionals include:

- Access to skilled Mold Makers.

- Custom Injection Molds for specific designs.

- Advanced production techniques for weight reduction.

- Timely delivery of parts with consistent quality.

Lightweight Design Trends

Lightweight design is evolving. Injection Molding technology is advancing. Future trends include:

- Increased use of bio-based materials.

- Smarter designs for even lighter parts.

- Enhanced mold technology for precision.

An experienced Injection Mould Company stays ahead of these trends.

Lightweight parts are transforming industries. An Injection Mould Company ensures their efficient design and production. Using advanced Injection Molding, skilled Mold Makers, and custom Injection Molds, they create parts that are both light and durable.

Partnering with an experienced team guarantees success. Choose a trusted Injection Mould Company for your lightweight part needs. Reduce weight, improve efficiency, and stay ahead in your industry.