Team collaboration is essential for success. Rapid Prototyping helps teams work better. It speeds up processes and aligns goals. Working with an experienced Injection Mould Company makes it even more effective.

This article explains how Rapid Prototyping improves teamwork.

What is Rapid Prototyping?

A Quick Overview

Rapid Prototyping creates models fast. These prototypes help teams visualize ideas.

Role in Collaboration

Teams use prototypes to share concepts. Everyone can see and give feedback.

Why Collaboration Matters

Unified Goals

Collaboration ensures everyone shares the same vision.

Faster Decisions

Teams solve problems quicker by working together.

Better Outcomes

Collaboration leads to better designs and innovations.

Key Benefits of Rapid Prototyping for Teams

1. Visual Clarity

Prototypes show designs clearly. It reduces misunderstandings.

2. Immediate Feedback

Teams test and adjust designs faster.

3. Cross-Department Input

Designers, engineers, and marketers all contribute.

4. Encourages Innovation

Prototypes inspire new ideas.

How an Injection Mould Company Enhances Collaboration

Expertise

An experienced Injection Mould Company brings valuable skills.

Material Knowledge

They help teams choose the best materials.

Technology Access

Modern tools streamline prototype creation.

Consistent Support

Reliable companies keep projects on track.

Steps to Boost Teamwork Using Rapid Prototyping

1. Define Goals Early

Start with clear objectives.

2. Share Prototypes Regularly

Show progress to all team members.

3. Use Feedback Loops

Improve designs based on team suggestions.

4. Partner with Experts

Work with a trusted Injection Mould Company.

Challenges in Collaboration

Communication Barriers

Misunderstandings slow progress.

Varying Expectations

Different departments may have conflicting goals.

Limited Resources

Time and budget constraints can hinder teamwork.

Solutions to Overcome Challenges

Clear Communication

Hold regular meetings to discuss updates.

Aligned Goals

Ensure everyone understands project priorities.

Resource Planning

Allocate time and budget effectively.

Trust Professionals

An Injection Mould Company helps solve resource issues.

Real-World Applications

Consumer Products

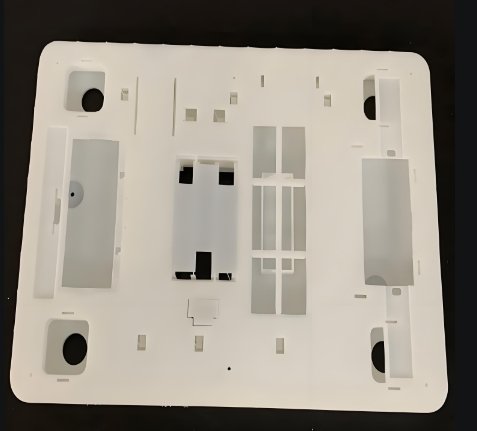

Teams design and test items like electronics faster.

Automotive

Prototypes of car parts improve collaboration across teams.

Medical Devices

Healthcare teams create accurate prototypes for testing.

Packaging

Design and marketing teams work together to create innovative packaging.

Technology Driving Collaboration

3D Printing

Teams produce prototypes quickly and review them together.

CNC Machining

High-precision prototypes support detailed discussions.

Virtual Prototyping

Digital models allow global teams to collaborate.

Measuring Collaboration Success

Faster Turnaround

Prototypes get approved quicker.

Fewer Revisions

Improved teamwork reduces errors.

Increased Innovation

New ideas emerge from shared input.

Higher Team Satisfaction

Collaboration strengthens team morale.

How to Choose the Right Injection Mould Company

Proven Track Record

Look for companies with successful collaborations.

Advanced Tools

Choose companies with modern prototyping technology.

Material Expertise

Ensure they offer diverse material options.

Strong Communication

Reliable companies maintain open communication.

Future of Collaboration with Rapid Prototyping

AI Integration

Artificial intelligence will suggest design improvements.

Global Collaboration

Teams will use virtual tools to work across continents.

Faster Prototyping

Emerging technologies will reduce lead times.

Sustainable Solutions

Eco-friendly materials will make collaboration greener.

Rapid Prototyping changes how teams collaborate. It improves communication, speeds up feedback, and aligns goals. Partnering with an experienced Injection Mould Company enhances these benefits.

Strong collaboration leads to better designs and faster product launches. By leveraging Rapid Prototyping, teams can innovate and succeed in competitive markets. This process not only boosts teamwork but also ensures long-term success.