In today’s fast-paced world, innovation is crucial. Companies need to develop new products quickly. Traditional methods are slow and costly. Rapid Prototyping is a game-changer. It speeds up the process and allows for faster improvements. With the help of an Injection Mould Company, businesses can take advantage of Rapid Prototyping to bring innovative products to market.

What is Rapid Prototyping?

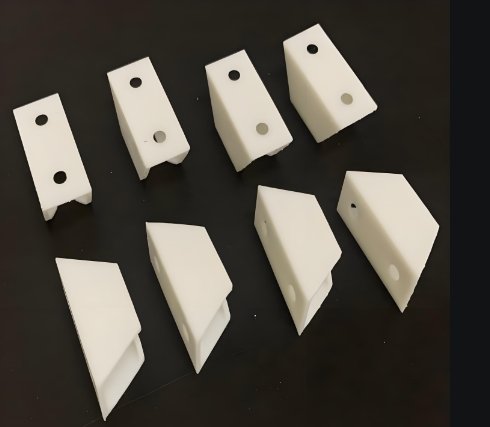

Rapid Prototyping refers to the quick creation of prototypes. These are early models of products. They help businesses test ideas before full-scale production. Rapid Prototyping uses different techniques like 3D printing, CNC machining, and injection molding. These methods reduce production time and costs.

The Need for Speed in Innovation

Faster Time to Market

In today’s competitive market, speed matters. The faster a company brings a product to market, the more likely it is to succeed. Rapid Prototyping speeds up product development. It helps businesses test and refine products faster.

Staying Ahead of Competitors

Companies that innovate faster have an edge. Rapid Prototyping helps them stay ahead of the competition. By quickly developing and testing new ideas, businesses can bring better products to market faster.

Testing Ideas Quickly

Testing ideas quickly is essential. Rapid Prototyping allows businesses to test concepts before making significant investments. This reduces risk and ensures that only the best ideas move forward.

Rapid Prototyping in the Design Process

Streamlining Design Iterations

Designing a product takes time. But with Rapid Prototyping, companies can make quick changes. Prototypes can be modified easily. This means that businesses can test, fail, and succeed much faster.

Reducing Design Flaws

Early-stage prototypes help identify design flaws. This prevents expensive mistakes in the later stages of production. Rapid Prototyping allows for continuous improvement.

Enhancing Creativity

Rapid Prototyping encourages creativity. Designers can experiment without the fear of high costs. This leads to more innovative and creative solutions.

The Role of an Injection Mould Company

Expertise in Molding and Materials

An Injection Mould Company brings expertise in molding and materials. They understand the best materials for prototypes. This ensures high-quality prototypes that closely resemble the final product.

Precision and Accuracy

Prototypes need to be accurate. An Injection Mould Company ensures precision during production. They use advanced tools and machines to create prototypes that meet exact specifications.

Scalability for Production

Once a prototype is tested and perfected, an Injection Mould Company can transition it into mass production. This ensures that the product can be manufactured at scale without losing quality.

Benefits of Rapid Prototyping for Innovation

Speed

The most significant advantage of Rapid Prototyping is speed. Prototypes are made quickly. This shortens development time and speeds up the innovation process.

Flexibility

Rapid Prototyping allows for flexibility in design. Changes can be made at any stage of development. This flexibility helps companies adapt quickly to new ideas and market needs.

Cost-Effectiveness

Traditional methods of prototyping require expensive tooling. Rapid Prototyping eliminates these costs. It allows businesses to test products without spending a lot of money.

Better Communication

Prototypes improve communication between teams. Visual representations make it easier to explain ideas. This helps teams collaborate more effectively.

Applications of Rapid Prototyping in Innovation

Product Development

Rapid Prototyping is widely used in product development. It helps companies develop better products faster. By testing and refining ideas quickly, companies can bring innovative products to market sooner.

Consumer Electronics

The electronics industry benefits greatly from Rapid Prototyping. Prototypes allow for testing of new devices and technology before they are mass-produced.

Automotive Industry

In the automotive industry, prototypes are used to test parts and components. This helps manufacturers ensure that products are safe, functional, and cost-effective.

Medical Devices

Rapid Prototyping is also used in the medical field. It helps create custom devices tailored to individual patients. This can improve treatment outcomes and overall healthcare.

How Rapid Prototyping Accelerates Product Testing

Early-Stage Testing

Rapid Prototyping enables early-stage testing. Prototypes can be tested in real-world conditions. This helps identify any issues before full-scale production.

Gathering Customer Feedback

Prototypes can be used to gather customer feedback. This ensures that the final product meets the needs of the target market.

Refining the Design

Based on feedback, designers can refine the prototype. This iterative process results in a better, more reliable product.

Overcoming Challenges with Rapid Prototyping

Cost Management

While Rapid Prototyping is cost-effective, the costs can still add up. Managing the cost of multiple iterations is key to staying within budget.

Material Selection

Choosing the right materials for prototypes is essential. An Injection Mould Company can help select the best materials for the job. This ensures that prototypes are both functional and durable.

Design Complexity

Some designs are complex and may require advanced prototyping techniques. Rapid Prototyping methods can handle complex designs, but it’s essential to work with experts to ensure success.

Rapid Prototyping is a game-changer for innovation. It speeds up the design process, reduces costs, and allows for greater creativity. With the support of an Injection Mould Company, businesses can test, refine, and manufacture innovative products quickly. In today’s fast-paced world, the ability to innovate quickly is essential. Rapid Prototyping gives businesses the tools they need to stay ahead of the competition.