Improving the precision of injection molds is essential in producing high-quality parts. Precision ensures that every part meets the exact specifications, reducing waste and saving costs. Achieving precision requires paying attention to various factors throughout the mold-making process. In this article, we’ll discuss five ways to improve precision in injection molds.

Optimize Mold Design

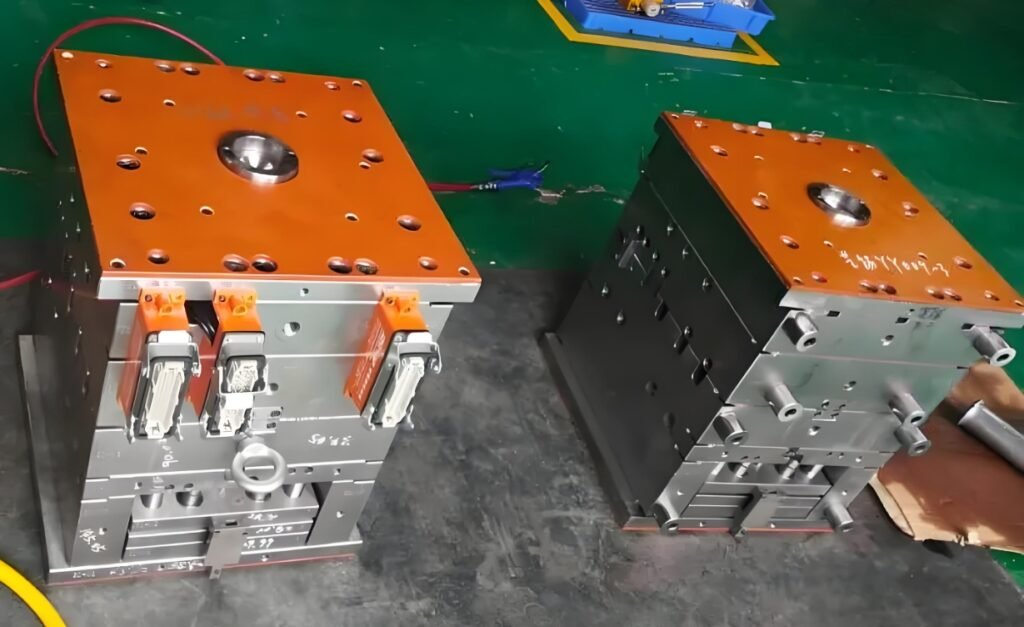

Good mold design is the first step to achieving precision. A well-designed mold ensures that every cavity is correctly shaped and aligned. This results in uniform parts. The design should consider factors like material flow, cooling channels, and part ejection. These elements impact the final product’s accuracy.

Using 3D modeling software can help improve design precision. This software allows mold maker to create detailed digital designs. Engineers can simulate how the mold will function before actual production begins. This process helps identify and fix potential design issues. Precision in design leads to precise parts.

Use High-Quality Materials

The material used to make the mold directly affects its precision. Low-quality materials can wear out quickly. This reduces the accuracy of the mold over time. Using high-quality steel or aluminum increases the mold’s durability. It maintains precision throughout many production cycles.

Different parts may require different mold materials. A mold maker must choose the right material for each project. Some materials offer better thermal stability, while others are resistant to wear. The material’s quality also affects the surface finish of the final part. Choosing the best material helps ensure consistent precision.

Maintain Tight Tolerances

Tight tolerances are critical for improving mold precision. Tolerance is the allowable deviation from the exact dimensions of the part. Lower tolerances mean higher precision. During the mold-making process, it’s important to measure every component carefully. Ensuring that all parts of the mold fit perfectly together is key to precision.

Using advanced machining techniques can help achieve tighter tolerances. CNC (Computer Numerical Control) machines are known for their ability to produce precise parts. They can machine mold components with extreme accuracy. Mold maker should also check the tolerance of each mold component regularly. Regular checks ensure that the mold stays within tolerance limits over time.

Improve Mold Cooling Systems

The cooling system in a mold plays a big role in precision. Uneven cooling can lead to warping or shrinkage in the final product. These defects reduce precision. To improve precision, mold maker must ensure that the cooling channels are evenly distributed. This helps cool the mold uniformly and prevents defects.

Using advanced cooling technologies like conformal cooling can also improve precision. Conformal cooling channels are custom-shaped to follow the contours of the mold. This results in more efficient and even cooling. By controlling the cooling process, mold maker can reduce defects and achieve higher precision.

Implement Regular Maintenance

Regular maintenance is crucial to maintaining precision over time. Injection molds experience wear and tear during production. If left unchecked, this can reduce the accuracy of the mold. Regular cleaning and maintenance help extend the mold’s life and keep it functioning at its best.

Inspecting the mold after each production run is a good practice. Check for any signs of wear, damage, or misalignment. If any issues are found, fix them immediately. Replacing worn parts helps maintain the mold’s precision. Keeping a maintenance schedule ensures that the mold always produces accurate parts.

Improving precision in injection molding is important for producing high-quality, accurate parts. Precision starts with good mold design, ensuring that every detail is carefully planned. Using high-quality materials and maintaining tight tolerances further improves precision. An efficient cooling system helps prevent defects, while regular maintenance keeps the mold performing well over time.

By following these five key steps, mold makers can achieve greater precision in their molds. This leads to better product quality and more efficient production. Injection molding precision is a combination of design, materials, machining, and maintenance. When all these elements work together, the result is highly accurate and reliable parts.