How-Tutorials

Bubbles in injection molded parts are a common issue in manufacturing. These bubbles can weaken the...

Injection molding is a popular manufacturing process. It’s used to create plastic parts by injecting...

Injection molding is a common manufacturing process used to create a wide range of plastic parts...

Injection molding is one of the most efficient and popular manufacturing methods for producing...

Overmolding is a process that allows the creation of multi-material parts. It involves using...

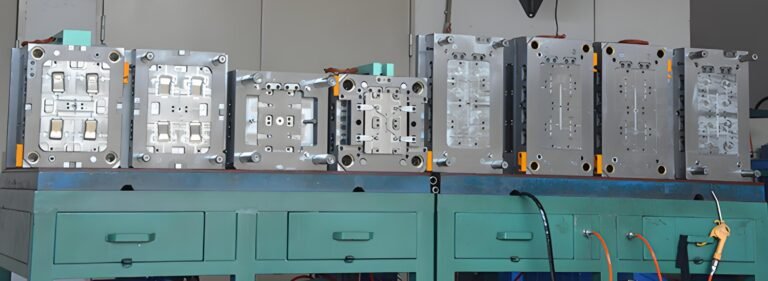

In the injection molding process, mold wear and tear is a common issue that affects productivity and...

In injection molding, gate location plays a critical role. It affects the flow of molten material...

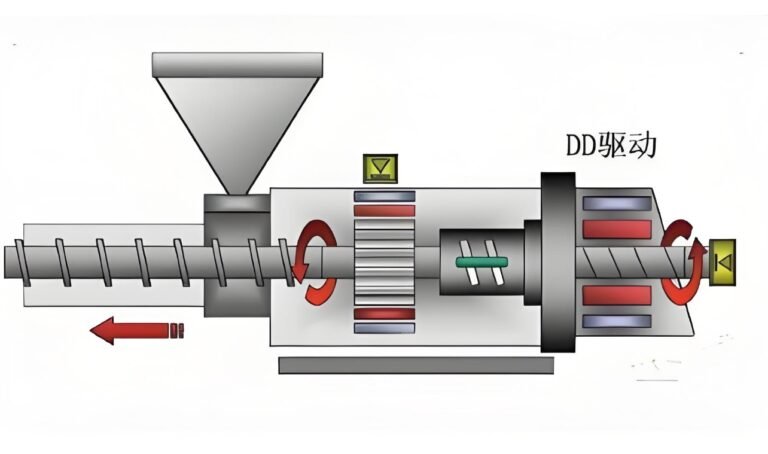

Injection pressure plays a critical role in the injection molding process. It determines how...

Jetting is a common defect in injection molding. It occurs when the molten plastic flows too quickly...

Hot runner systems have become a common choice in the injection molding process. They provide many...