The automotive industry demands excellence. To meet this need, manufacturers rely on Automotive Injection Molds. Precision, durability, and quality drive mold designs. Skilled Mold Makers ensure each mold meets high standards. This article explores these standards and their role in premium automotive parts.

What Are Automotive Injection Molds?

Definition

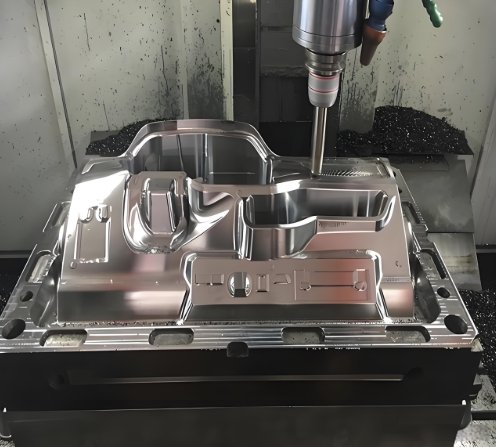

Automotive Injection Molds shape vehicle parts. Molten material, usually plastic or metal, is injected into these molds. The material cools, hardens, and takes the required shape.

Purpose

The molds create parts with consistent quality. They ensure precision and reliability in every vehicle component.

Role of the Mold Maker

A Mold Maker designs, builds, and maintains these molds. Their expertise ensures each mold meets strict industry standards.

Why Standards Matter

1. Ensuring Consistency

Standardized molds produce uniform parts. This consistency is crucial for automotive safety and functionality.

2. Improving Durability

High standards ensure molds can handle heavy production cycles. They create durable parts that last.

3. Enhancing Precision

Standards ensure exact dimensions. Even small errors can affect vehicle performance.

4. Meeting Industry Regulations

Molds must meet global automotive regulations. High standards ensure compliance.

Key Standards in Injection Molding

1. Material Selection

The material used affects part quality. Common options include high-strength plastics and lightweight alloys. Standards guide material selection.

2. Dimensional Accuracy

Molds must meet precise dimensional tolerances. Standards dictate acceptable limits for errors.

3. Surface Finish

The surface finish affects appearance and performance. Standards ensure smooth, defect-free finishes.

4. Cycle Time Optimization

Efficient cycle times reduce production costs. Standards ensure molds balance speed and quality.

5. Durability Testing

Molds undergo rigorous testing. This ensures they can withstand long production runs.

The Role of the Mold Maker in Upholding Standards

1. Design Expertise

A Mold Maker designs molds to meet exact specifications. They use advanced tools like CAD software.

2. Material Knowledge

Mold makers select the right materials for durability and precision. Their choices affect the mold’s lifespan.

3. Prototyping and Testing

Before mass production, molds are tested. Prototyping ensures the design meets all standards.

4. Maintenance and Repairs

Regular maintenance ensures molds stay within standards. Mold makers handle repairs and adjustments.

Applications of Automotive Injection Molds

1. Exterior Components

Molds create bumpers, grilles, and door panels. These parts require strength and a flawless finish.

2. Interior Components

Dashboards, armrests, and consoles rely on molds. They demand precise designs and smooth surfaces.

3. Engine Components

Molds produce engine covers and housings. These parts must withstand heat and pressure.

4. Lighting Parts

Headlights and tail lights use injection molds. Their complex shapes require high precision.

5. EV Components

Electric vehicles need lightweight, durable parts. Injection molds make battery casings and motor housings.

Challenges in Meeting Standards

1. Complex Designs

Modern vehicles require intricate components. Designing molds for these parts is challenging.

2. Material Compatibility

Different materials behave differently. Molds must match the material’s properties.

3. Maintaining Tolerances

Small deviations can cause big problems. Ensuring tight tolerances is essential.

4. Cost of Customization

Custom molds are expensive. However, they ensure premium quality.

5. Environmental Standards

Molds must support eco-friendly production. This includes using recycled materials.

Advanced Techniques for High Standards

1. Hot Runner Systems

These systems improve material flow. They reduce waste and defects.

2. Gas-Assisted Molding

This method creates hollow parts. It’s ideal for lightweight components.

3. Multi-Cavity Molds

These molds produce multiple parts in one cycle. They increase efficiency.

4. Overmolding

Overmolding combines materials into one part. It’s perfect for soft-touch components.

5. Smart Molds

Smart molds feature sensors. They monitor temperature and pressure during production.

Future Trends in Automotive Injection Molding

1. Sustainability

Eco-friendly practices are becoming standard. This includes using recyclable materials and reducing waste.

2. Digital Integration

Digital tools improve mold design. They ensure precision and speed.

3. Global Collaboration

Mold makers work across borders. This ensures molds meet international standards.

4. Focus on Quality

As technology advances, quality remains a priority. High standards ensure reliable components.

How Injection Molds Transform the Industry

1. Reducing Costs

Injection molding reduces production costs. High output rates save money.

2. Improving Vehicle Safety

Premium molds ensure high-quality parts. This enhances vehicle safety.

3. Supporting Customization

Injection molds allow for unique designs. This meets diverse consumer demands.

4. Boosting Efficiency

Modern molds increase production speed. This benefits manufacturers and consumers.

5. Enabling Lightweight Vehicles

Molds create lightweight parts. This improves fuel efficiency and reduces emissions.

Automotive Injection Molds set the standard for modern vehicle parts. Skilled Mold Makers design and maintain these molds with precision. High standards ensure quality, consistency, and durability. They transform the automotive industry, enabling safer, lighter, and more efficient vehicles. As technology evolves, these standards will continue to rise. Injection molding remains the cornerstone of premium automotive manufacturing.