The automotive injection molds industry follows strict standards. These standards ensure the production of high-quality, reliable parts. A professional mold maker follows precise guidelines to maintain these standards. Consistency is essential in automotive manufacturing. Every mold must meet tight tolerances. This is why quality control is so important.

Importance of Injection Mold Standards

1. Precision in Manufacturing

Automotive injection molds must be precise. Tolerances need to be tight. Even the smallest deviation can lead to part failure. This precision guarantees that each component fits perfectly into the vehicle.

2. Safety Considerations

Safety is a top priority in the automotive industry. Injection molds for automotive parts must be made from durable materials. They must meet safety standards like impact resistance and heat tolerance. A mold maker ensures that these qualities are present in every part.

3. Durability and Longevity

Automotive parts undergo heavy wear and tear. Automotive injection molds must produce components that last. The mold material must be durable enough to handle mass production without losing its precision.

4. Meeting Industry Regulations

Every part must meet specific regulations. These include safety, performance, and environmental standards. Mold makers ensure that their molds follow these guidelines.

Key Standards for Automotive Injection Molds

1. ISO 9001 Quality Standards

ISO 9001 is a globally recognized standard for quality management. It focuses on continuous improvement. This standard helps mold makers deliver consistent and high-quality products.

2. Automotive Quality Standards (IATF 16949)

IATF 16949 sets specific quality standards for the automotive industry. It includes requirements for process control, material quality, and production efficiency. It ensures that automotive parts meet the industry’s high standards.

3. Material Selection Standards

Choosing the right material is essential for creating strong, durable parts. Automotive injection molds use materials that can withstand heat, pressure, and other harsh conditions. Materials must comply with automotive standards for performance and safety.

4. Tolerance Standards

Tolerances define how much a part can vary from its design. Tight tolerances are necessary for precise fitting and functionality. These standards are critical in producing complex automotive parts with multiple components.

5. Environmental Standards

Automotive parts must meet environmental standards. The materials used in automotive injection molds must be environmentally friendly. They must also meet regulations for recycling and waste management.

The Role of a Mold Maker in Ensuring Standards

1. Expertise in Design

A mold maker is responsible for the mold’s design. The design must follow the necessary standards. A skilled mold maker uses advanced software to create precise molds. The design process includes selecting the right material and ensuring that the mold will produce quality parts.

2. Material Selection

Selecting the right material is key. A mold maker chooses materials based on durability and the part’s specific requirements. Materials must meet the standards for heat resistance, flexibility, and impact strength.

3. Quality Control and Testing

Once the mold is designed and fabricated, the next step is testing. A mold maker ensures that the mold produces parts that meet the required standards. They perform quality checks to ensure the mold’s accuracy, durability, and overall performance.

4. Manufacturing Process Control

During production, mold makers monitor the process closely. They ensure that the molds maintain their precision and that the parts meet the required standards. If a defect is found, the process is adjusted immediately to prevent it from happening again.

5. Meeting Production Deadlines

Production timelines are critical in the automotive industry. A mold maker ensures that the molds are ready on time, without compromising on quality. Timely production is essential for meeting automotive assembly line schedules.

Challenges in Maintaining Injection Mold Standards

1. Complex Designs

As automotive parts become more complex, the injection mold design process becomes more challenging. Parts may have multiple intricate features or need to combine various materials. Achieving precision in such designs requires advanced technology and expert craftsmanship.

2. Material Compatibility

Different materials have unique properties. A mold maker must choose materials that work well together in multi-material molds. The wrong material choice can affect the performance and durability of the parts.

3. Variability in Manufacturing Conditions

Changes in temperature, pressure, and humidity can affect the molding process. Consistent conditions are necessary to meet the standards. Mold makers need to control these variables to ensure that the molds perform optimally.

4. Ongoing Maintenance

Molds require regular maintenance to keep up with production demands. Regular inspections help identify any wear or damage. If the mold is not maintained properly, it can result in defective parts.

Technological Advancements in Automotive Injection Molds

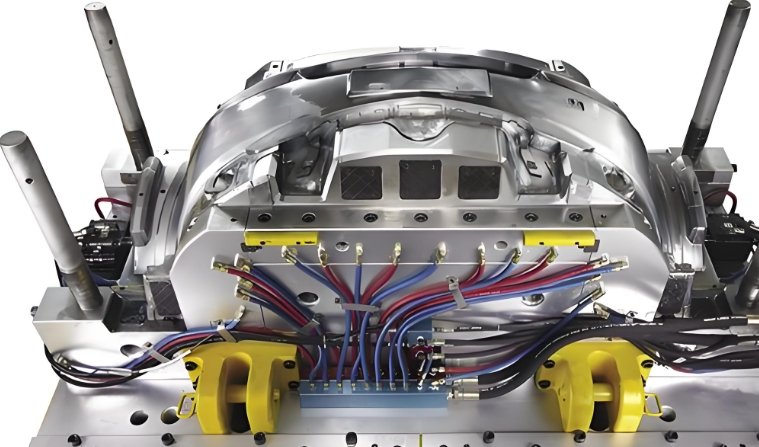

1. Multi-Material Molding

Multi-material molding allows for the use of two or more materials in a single part. This creates stronger, lighter components. Automotive injection molds are increasingly being designed to accommodate multiple materials.

2. Automation in Molding

Automated systems are improving the accuracy and speed of injection molding. Robotics are used to handle materials and monitor the molding process. Automation helps meet production deadlines and improves the overall quality of the parts.

3. Advanced Mold Cooling

Efficient cooling systems help reduce cycle times. They ensure that molds remain at optimal temperatures throughout production. Fast cooling speeds up production without sacrificing quality.

4. 3D Printing in Prototyping

3D printing is used for rapid prototyping. This allows mold makers to quickly create and test mold designs before going into full-scale production. 3D printing speeds up the design process and reduces costs.

The standards for automotive injection molds are strict, but they ensure that the industry produces reliable, safe, and high-quality parts. Mold makers play a critical role in maintaining these standards. By following industry regulations, using the right materials, and maintaining strict quality control, mold makers help the automotive industry thrive.