Injection molding plays a crucial role in the development of advanced automotive structures. Automotive Injection Molds are used to create parts that offer high strength and precision. These parts must meet strict safety standards and perform well in demanding environments. Skilled Mold Makers are essential in ensuring the parts are both functional and durable. This article explores how injection molding is used in the automotive industry to create advanced automotive structures.

What is Injection Molding?

1. Definition

Injection molding is a manufacturing process. It involves injecting melted material into a mold to create parts. These parts harden as they cool.

2. Materials Used

Various materials are used in injection molding, including plastics, metals, and composites. Automotive Injection Molds often use high-strength thermoplastics, such as polypropylene, ABS, and polycarbonate.

3. Process Overview

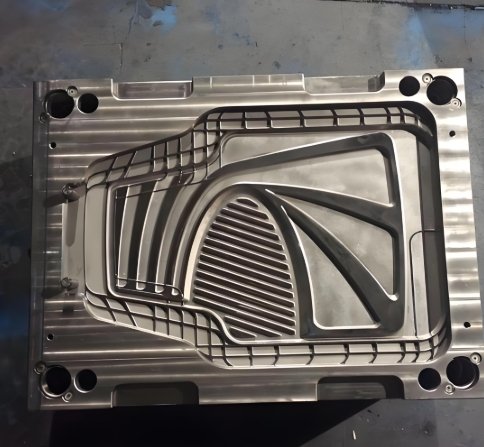

The injection molding process starts with melting the material. It is then injected into a mold under high pressure. The mold shapes the material into the desired part.

Role of Automotive Injection Molds in Advanced Structures

1. Strength and Durability

Automotive Injection Molds are essential for parts that need to withstand high stress. These molds are used to create parts for the car body, engine components, and other critical areas. The materials used provide the necessary strength and durability.

2. Precision and Accuracy

Parts made with Automotive Injection Molds need to be precise. Even small errors can lead to poor performance or safety risks. Mold Makers ensure high precision during the molding process.

3. Lightweight Structures

In modern automotive design, lightweight structures are crucial. Using advanced materials and molding techniques, Mold Makers can produce strong, yet lightweight parts. This reduces the vehicle’s overall weight, improving fuel efficiency and performance.

Key Benefits of Using Automotive Injection Molds

1. High Volume Production

Injection molding allows for high-volume production. Once the mold is created, thousands of parts can be made quickly. This makes it ideal for producing large quantities of parts used in automotive manufacturing.

2. Complex Shapes and Designs

Automotive Injection Molds can create parts with complex shapes. These molds can handle intricate designs that would be difficult or impossible to create with other manufacturing methods.

3. Consistent Quality

Injection molding offers consistent quality. Each part produced is nearly identical to the next. This is essential in automotive manufacturing, where consistency and quality control are critical.

4. Reduced Waste

The injection molding process is efficient. Materials are injected precisely into the mold, reducing waste. This makes it a cost-effective option for manufacturing automotive parts.

Applications of Automotive Injection Molds

1. Car Body Parts

Injection molding is used to create car body parts, including bumpers, panels, and grilles. These parts need to be both strong and lightweight. Automotive Injection Molds help achieve these qualities.

2. Interior Components

Parts such as dashboard components, door panels, and trim pieces are made using injection molding. These parts often require complex designs and high precision.

3. Engine Components

Engine components, such as housings, intake manifolds, and other critical parts, are often produced using injection molding. These parts must withstand high temperatures and pressures.

4. Chassis Components

Injection molding is used to create chassis components, such as suspension mounts and brackets. These parts must be durable and able to support heavy loads.

5. Lighting and Electrical Components

Injection molding is also used for lighting components, including headlight housings and tail light covers. Electrical components, such as connectors and switches, are also made using Automotive Injection Molds.

The Role of Mold Makers in Advanced Automotive Structures

1. Design and Prototyping

Mold Makers play a vital role in designing the molds for advanced automotive structures. They use CAD software to create detailed designs and prototypes. This allows manufacturers to test the molds before full-scale production.

2. Material Selection

Choosing the right material is critical. Mold Makers select materials based on the part’s requirements. They consider factors such as strength, heat resistance, and cost.

3. Precision Engineering

Advanced automotive structures require precision engineering. Mold Makers ensure the molds are accurate and able to produce high-quality parts.

4. Tooling and Maintenance

Once the molds are designed, Mold Makers create the tooling required for production. They also maintain the molds to ensure they continue to perform effectively over time.

Challenges in Molding Advanced Automotive Structures

1. Complexity of Designs

Modern automotive structures often feature complex designs. These parts require molds with intricate features. The challenge for Mold Makers is to create molds that can produce these parts with precision.

2. Material Selection

The materials used in automotive injection molding must meet specific requirements. Choosing the wrong material can lead to weak or brittle parts. Mold Makers must carefully select materials based on the application.

3. Cost Considerations

While injection molding is cost-effective, the initial setup costs can be high. The cost of creating complex molds can be a challenge for manufacturers. However, the long-term benefits of high-volume production make it a viable option.

Future Trends in Automotive Injection Molds

1. Sustainability

Sustainability is becoming a key focus in the automotive industry. Automotive Injection Molds will increasingly use recyclable materials and processes that reduce waste.

2. Smart Materials

Smart materials, which respond to changes in temperature or pressure, are being explored for automotive applications. These materials could lead to more advanced automotive structures in the future.

3. Additive Manufacturing

Additive manufacturing, or 3D printing, is becoming more integrated with injection molding. This allows Mold Makers to create complex mold designs more efficiently and with greater flexibility.

Automotive Injection Molds are essential in creating advanced automotive structures. They allow for high-volume production of strong, durable, and lightweight parts. Mold Makers play a crucial role in selecting materials, designing molds, and ensuring precision. As automotive technology advances, the role of injection molding will continue to grow. New materials, designs, and techniques will drive innovation in the industry, leading to even more advanced automotive structures