IoT devices are everywhere. Smart homes, healthcare, and industries rely on them. These devices need precision, durability, and lightweight materials. Electronic injection molding is the best method for making them. Mold makers create small, complex parts with high accuracy.

1. Why IoT Devices Need Injection Molding

1.1 Precision for Miniature Components

IoT devices have tiny sensors and circuit housings. Injection molding ensures exact dimensions.

1.2 Lightweight and Durable Materials

Smart technology requires strong yet light parts. Molded plastics provide both.

1.3 Mass Production at Low Cost

Injection molding allows high-volume production. This reduces manufacturing costs.

1.4 Heat and Chemical Resistance

Many IoT devices work in extreme conditions. Molded plastics resist heat, moisture, and chemicals.

1.5 Customization for Unique Designs

Smart gadgets need different shapes and sizes. Injection molding allows flexible designs.

2. Common IoT Devices Made with Injection Molding

2.1 Smart Home Devices

- Thermostats and smart locks

- Home security system casings

2.2 Wearable Technology

- Fitness trackers and smartwatches

- Wireless earbuds and hearing aids

2.3 Industrial IoT Components

- Smart sensors for automation

- Connected control panels

2.4 Healthcare and Medical IoT

- Remote patient monitoring devices

- Smart pill dispensers

2.5 Smart Consumer Electronics

- AI assistants and smart speakers

- Wireless charging stations

3. Key Materials for IoT Device Injection Molding

3.1 Polycarbonate (PC)

- High impact resistance

- Transparent for LED covers

3.2 Acrylonitrile Butadiene Styrene (ABS)

- Durable and lightweight

- Used in wearable tech

3.3 Polyetheretherketone (PEEK)

- Withstands high temperatures

- Used in industrial sensors

3.4 Liquid Silicone Rubber (LSR)

- Flexible and waterproof

- Ideal for medical IoT devices

3.5 Thermoplastic Polyurethane (TPU)

- Scratch-resistant and elastic

- Used in smartwatch bands

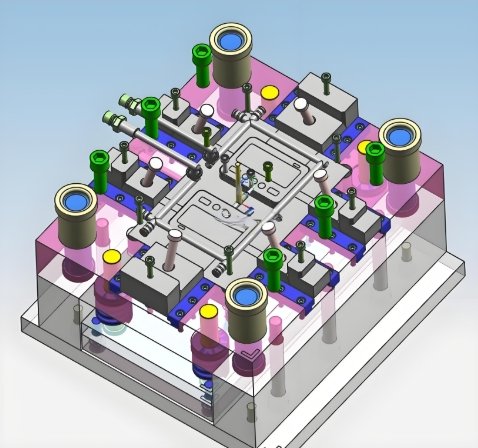

4. The Injection Molding Process for IoT Devices

4.1 Step 1: Designing the Mold

Mold makers create precise designs for each component.

4.2 Step 2: Material Selection

Engineers choose heat-resistant plastics.

4.3 Step 3: Injection Molding Production

Molten plastic fills high-precision molds.

4.4 Step 4: Cooling and Solidification

Parts cool quickly for dimensional stability.

4.5 Step 5: Quality Control and Testing

Every part undergoes strict testing for durability.

4.6 Step 6: Assembly and Integration

Molded parts are combined into final IoT devices.

5. Challenges in Injection Molding for IoT

5.1 Shrinking Component Sizes

IoT devices require micro-molding technology.

5.2 EMI Shielding for Wireless Devices

Plastic enclosures need coatings to block interference.

5.3 Balancing Strength and Flexibility

Wearables need both rigidity and comfort.

5.4 Waterproofing and Sealing

Many IoT devices require moisture resistance.

5.5 Sustainable Manufacturing Practices

Smart tech companies seek eco-friendly plastics.

6. Innovations in Electronic Injection Molding for IoT

6.1 Overmolding for Multi-Material Devices

Combines hard and soft plastics for better design.

6.2 Conductive Polymers for Wireless Charging

Allows plastics to carry electrical signals.

6.3 3D Printing for Rapid Prototyping

Speeds up new product development.

6.4 AI-Powered Quality Control

Reduces defects with automated inspections.

6.5 Smart Polymers for Adaptive Electronics

Materials that change properties based on environment.

7. Future Trends in IoT Device Injection Molding

7.1 Biodegradable Plastics for Eco-Friendly Gadgets

Sustainable materials will reduce waste.

7.2 Advanced Nanocoatings for Waterproofing

Enhances durability without adding weight.

7.3 AI and Machine Learning in Manufacturing

Optimizes production for higher efficiency.

7.4 More Compact and Lightweight Designs

Injection molding will support smaller, lighter devices.

7.5 Integration of Smart Sensors in Plastic Housings

IoT devices will have embedded sensing technology.

Electronic injection molding plays a key role in smart technology. Mold makers ensure precision, strength, and miniaturization. As IoT evolves, injection molding will continue shaping the future of connected devices.