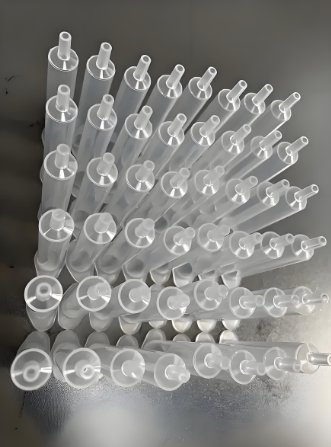

Medical tubing and connectors are essential in healthcare. They transport fluids, deliver oxygen, and support medical devices. Medical injection molding produces these parts with high precision. Mold makers design molds for durability, flexibility, and sterility.

Importance of Medical Tubing and Connectors

1. Essential for Patient Care

Medical tubing delivers medication, fluids, and gases. Connectors ensure a secure, leak-free fit.

2. Prevents Contamination

Sterile tubing and connectors protect patients from infections.

3. Supports Life-Saving Equipment

They are used in ventilators, IV lines, dialysis machines, and more.

4. Ensures Consistent Performance

Medical-grade plastics maintain strength, flexibility, and chemical resistance.

5. Meets Strict Medical Standards

Each part must comply with FDA and ISO requirements.

Common Applications of Medical Tubing and Connectors

1. Intravenous (IV) Tubing

IV tubing delivers fluids, medications, and nutrients. It must be flexible and kink-resistant.

2. Catheter Tubing

Catheters help drain fluids and assist in surgeries. They must be soft and biocompatible.

3. Respiratory Tubing

Oxygen tubes and ventilator hoses deliver air to patients. They require precision to ensure airflow.

4. Dialysis Tubing

Dialysis machines use tubing to filter blood. It must be durable and chemical-resistant.

5. Feeding Tubes

These tubes provide nutrition to patients who cannot eat normally. They must be safe for prolonged use.

6. Surgical Suction Tubing

Used to remove fluids during surgery. It must be strong and flexible.

7. Luer Lock and Quick Connectors

These connectors ensure secure attachment between tubes and devices.

8. Blood Collection Tubes and Ports

Used in diagnostic testing and blood transfusions. They require airtight seals.

Materials Used in Medical Injection Molding for Tubing and Connectors

1. Polyvinyl Chloride (PVC)

PVC is flexible, durable, and resistant to chemicals. It is used in IV and respiratory tubing.

2. Silicone

Silicone is soft, biocompatible, and heat-resistant. It is used in catheters and surgical tubing.

3. Polyurethane (PU)

PU is flexible and strong. It is used in catheter and wound drainage tubes.

4. Polyethylene (PE)

PE is lightweight and chemical-resistant. It is used in feeding tubes and dialysis tubing.

5. Thermoplastic Elastomers (TPEs)

TPEs provide flexibility and durability. They are used in medical tubing seals and gaskets.

6. Polycarbonate (PC)

PC is clear and impact-resistant. It is used in rigid connectors and blood collection ports.

How Mold Makers Ensure High-Quality Medical Tubing and Connectors

1. Precision Mold Design

Mold makers create detailed designs to ensure uniform wall thickness and flexibility.

2. Advanced Material Selection

Choosing the right material is crucial for performance and safety.

3. Cleanroom Manufacturing

Production must take place in a sterile environment to prevent contamination.

4. High-Quality Molding Techniques

Injection molding ensures smooth, defect-free surfaces for tubing and connectors.

5. Rigorous Quality Control

Products undergo strict testing for strength, flexibility, and sterility.

Advantages of Medical Injection Molding for Tubing and Connectors

1. High Precision and Consistency

Injection molding ensures each part meets exact specifications.

2. Cost-Effective Mass Production

Large quantities can be produced at low costs.

3. Sterility and Biocompatibility

Medical-grade plastics meet strict hygiene standards.

4. Customization for Specific Applications

Different shapes, sizes, and materials can be tailored for medical needs.

5. Strong and Flexible Materials

Injection-molded parts maintain durability while remaining lightweight.

Challenges in Medical Injection Molding for Tubing and Connectors

1. Meeting Regulatory Standards

Each product must comply with FDA and ISO medical guidelines.

2. Preventing Contamination

Sterile manufacturing conditions are critical.

3. Maintaining Flexibility and Strength

The right material balance is needed to ensure tubing does not crack or kink.

4. Achieving Secure Connections

Connectors must fit tightly to prevent leaks or detachment.

5. Managing Production Costs

High-quality materials and cleanroom production can be expensive.

Innovations in Medical Injection Molding for Tubing and Connectors

1. Advanced Micro-Molding

Smaller, more precise parts improve performance in medical devices.

2. Biodegradable Plastics

Eco-friendly materials reduce medical waste.

3. Multi-Layer Tubing

Different materials combined in one tube enhance strength and flexibility.

4. Smart Tubing Technology

Embedded sensors can monitor flow and pressure in medical tubes.

5. High-Speed Automation

Robotic systems improve efficiency and reduce human errors.

Future Trends in Medical Injection Molding for Tubing and Connectors

1. More Biocompatible Materials

New materials will enhance safety and comfort.

2. Greater Customization for Patient Needs

Injection molding will allow more specialized tubing and connectors.

3. Faster and More Efficient Production

Automation and AI will improve manufacturing speed and accuracy.

4. Stricter Quality and Safety Standards

Regulations will continue to evolve for better patient safety.

Medical injection molding plays a vital role in producing medical tubing and connectors. These components are essential for patient care. Mold makers ensure precision, safety, and sterility in every part. As technology advances, medical tubing and connectors will become even more efficient and reliable.