Producing high-strength plastic parts demands precision. An Injection Mould Company specializes in creating durable components. These parts are essential for industries like automotive, aerospace, and construction.

1. The Role of Injection Molding

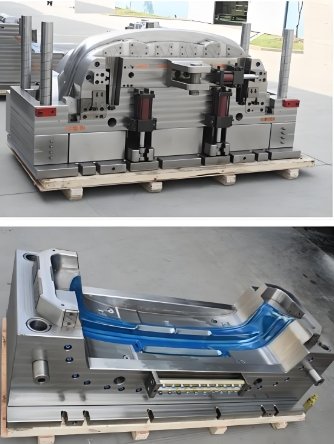

Injection Molding forms the backbone of manufacturing. It creates precise and strong plastic parts. The process involves injecting molten plastic into molds. Skilled Mold Makers ensure every detail meets standards.

2. Importance of High-Strength Plastic Parts

Durable plastic parts resist stress. They withstand extreme conditions. Industries rely on these parts for safety and performance. An Injection Mould Company ensures they meet these demands.

3. Advanced Materials for Strength

Materials matter in Injection Molding. Engineers use reinforced plastics. These include:

- Glass-filled nylon

- Carbon-fiber composites

- High-density polyethylene

These materials enhance strength. Experienced Mold Makers choose the right material for each application.

4. Precision in Mold Design

The mold determines part quality. Durable Injection Molds handle high pressure. They also ensure consistent results. An expert Mold Maker designs molds for optimal performance.

5. Applications of High-Strength Plastic Parts

These parts serve many industries:

- Automotive: Engine covers, brackets

- Aerospace: Lightweight panels

- Construction: Strong pipes, fittings

An Injection Mould Company tailors designs for each industry.

6. Challenges in Producing Strong Plastic Parts

Several challenges arise in production. These include:

- Material shrinkage

- Mold wear and tear

- Achieving tight tolerances

Experienced Mold Makers address these issues. They refine Injection Molds for superior results.

7. Innovations in Injection Molding

Technology improves Injection Molding. Automation ensures accuracy. Advanced cooling systems enhance mold performance. These innovations boost efficiency.

8. Importance of Skilled Mold Makers

A skilled Mold Maker is crucial. They craft molds with precision. Their expertise minimizes defects. This ensures durable plastic parts.

9. Mold Testing for Quality

Testing verifies mold performance. Simulations predict material behavior. Trial runs identify issues early. An Injection Mould Company relies on rigorous testing.

10. Cost Efficiency Through Injection Molding

Durable parts reduce long-term costs. They minimize maintenance needs. Efficient production saves resources. Injection Molding provides cost-effective solutions.

11. Why Choose an Injection Mould Company?

An experienced Injection Mould Company ensures quality. They use advanced technology. Skilled teams deliver consistent results. Clients benefit from durable, high-strength parts.

12. Customization for Industry Needs

Every industry has unique requirements. Custom Injection Molds address these. Engineers design parts to meet specific demands. Collaboration ensures success.

13. Sustainability in Production

Sustainable practices matter. Recycled materials and energy-efficient machines are common. Leading Injection Mould Companies adopt green solutions.

14. Long-Term Benefits of Strong Plastic Parts

High-strength plastic parts offer durability. They reduce repair costs. Lightweight materials improve efficiency. Industries rely on these advantages.

High-strength plastic parts drive innovation. They combine durability and functionality. An Injection Mould Company ensures exceptional results. With expert Mold Makers and advanced Injection Molding, they deliver quality Injection Molds every time.