As the world faces environmental challenges, industries are seeking ways to reduce their environmental footprint. Injection molding offers many benefits, but it also presents opportunities for sustainability. An experienced injection mould company can integrate sustainable practices into the molding process. These companies use advanced technologies and techniques to minimize waste, reduce energy use, and recycle materials. A skilled mold maker plays a vital role in ensuring that the entire production process is as eco-friendly as possible. In this article, we will explore how an injection mould company can adopt sustainable practices for injection molding and create products with a minimal environmental impact.

What is Injection Molding?

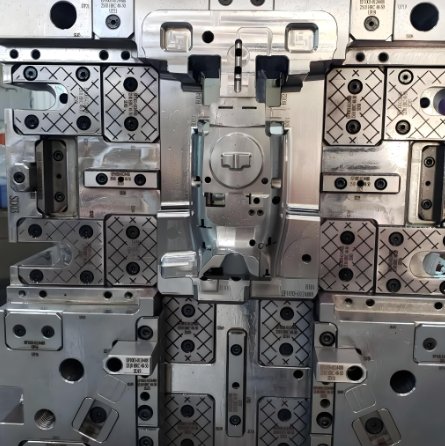

Injection molding is a manufacturing process where material is injected into a mold under high pressure. It’s a popular method for producing parts in various industries, from automotive to electronics. The process is efficient and can create high-quality parts in large volumes. However, the environmental impact of injection molding can be significant without proper management.

An injection mould company has the responsibility to make the molding process as sustainable as possible. This involves minimizing material waste, improving energy efficiency, and ensuring that the molds are durable and reusable. Sustainable practices start with the choice of materials and continue through the design and manufacturing stages.

Sustainable Materials in Injection Molding

The first step in creating a sustainable injection molding process is selecting eco-friendly materials. Traditional plastics, like polyethylene and polypropylene, are widely used in injection molding. While they are durable and versatile, they are often not biodegradable, leading to long-term environmental issues.

An experienced injection mould company can reduce this environmental impact by opting for biodegradable or recyclable materials. For example, bioplastics made from renewable resources like corn or sugarcane are a more eco-friendly alternative. These materials break down more easily than traditional plastics, reducing the amount of waste in landfills.

Another sustainable option is recycled plastic. By using recycled materials, an injection mould company reduces the demand for virgin plastic and helps lower the overall carbon footprint. A skilled mold maker will ensure that the recycled materials are properly processed and used in the mold design to maintain part quality.

Efficient Use of Energy in Injection Molding

Energy consumption is a major consideration for sustainability in injection molding. The injection molding process requires a considerable amount of energy, especially when heating the material to the right temperature and maintaining the mold at consistent temperatures.

An injection mould company can reduce energy consumption by investing in energy-efficient equipment. This includes using machines with variable-speed motors and high-performance heaters that consume less power. Additionally, some companies implement advanced temperature control systems that reduce energy waste during the molding process. These systems ensure that the mold temperature is maintained at the ideal level, reducing energy consumption and improving part consistency.

The mold maker also contributes to energy efficiency by designing molds that are optimized for fast and efficient cooling. Proper cooling reduces the time needed to solidify the molded parts, which can help minimize energy consumption during production.

Minimizing Waste in the Injection Molding Process

One of the key benefits of injection molding is its precision. Parts are molded with great accuracy, which helps reduce material waste. However, waste can still occur if the process is not optimized.

An experienced injection mould company focuses on minimizing waste during production. This starts with efficient mold design. A skilled mold maker will design molds that minimize scrap material and ensure the molding process uses as much of the material as possible. In some cases, the mold may even be designed to allow for the recycling of scrap material, further reducing waste.

Additionally, the injection mould company can implement closed-loop systems, where leftover material from the molding process is collected and reused. By recycling scrap material directly back into the production process, the company can significantly reduce waste and increase material efficiency.

The Role of a Mold Maker in Sustainable Production

The role of the mold maker is crucial in ensuring that the injection molding process is as sustainable as possible. A skilled mold maker can design molds that optimize material usage and minimize waste. They understand the importance of precise design to avoid errors and defects that lead to wasted resources.

The mold maker also plays a vital role in ensuring that the molds are durable and can withstand many cycles of use. High-quality molds can be reused for years, reducing the need for new molds and further contributing to sustainability efforts.

Advanced Technology for Sustainability

An injection mould company can also adopt advanced technologies to further enhance sustainability. For example, 3D printing technology is increasingly being used in the design and manufacturing of injection molds. 3D printing allows for the rapid prototyping of molds, reducing the need for traditional mold-making processes that can produce significant waste.

Another technology that can improve sustainability is automated monitoring systems. These systems track the entire production process, ensuring that it runs as efficiently as possible. By identifying areas where waste is occurring or energy is being wasted, the injection mould company can make adjustments to improve the process and reduce its environmental impact.

Sustainable Packaging for Injection Molds

Sustainability doesn’t end with the production process. Packaging is another area where an injection mould company can reduce its environmental impact. Traditional packaging materials like foam and plastic are often used to protect molded parts during shipping. These materials can be harmful to the environment, especially when they end up in landfills.

To address this, many injection mould companies are switching to eco-friendly packaging options. For example, biodegradable packing peanuts, recycled cardboard, and reusable containers are becoming more common in the industry. By adopting sustainable packaging practices, companies can further reduce their environmental footprint.

Benefits of Sustainable Practices in Injection Molding

Adopting sustainable practices in injection molding offers several benefits. First, it reduces the environmental impact of the manufacturing process, helping companies meet environmental regulations and improve their reputation as eco-conscious businesses.

Second, sustainable practices can lead to cost savings. By reducing waste, energy consumption, and material costs, an injection mould company can lower production expenses. This, in turn, can make the business more competitive in the market.

Finally, sustainable production practices ensure that the company is prepared for the future. As demand for eco-friendly products grows, businesses that prioritize sustainability will have a competitive advantage in the market.

In conclusion, sustainable production practices are essential for reducing the environmental impact of injection molding. By working with an experienced injection mould company, manufacturers can minimize waste, reduce energy consumption, and select eco-friendly materials. The mold maker plays a key role in designing molds that optimize material use and ensure that the process is as efficient as possible. With the right technologies and practices in place, injection molding can be a sustainable and environmentally responsible manufacturing method.