Medical parts demand precision. Even the smallest component must meet strict standards. An injection mould company specializes in creating these parts. They use advanced injection molding techniques. Skilled mold makers ensure every detail is perfect. High-quality injection molds guarantee consistency.

Why Precision Matters in Medical Parts

Small medical parts often have critical roles. They include items like surgical clips, connectors, and syringes. If these parts fail, patients face risks. Accuracy is not optional. An injection mould company ensures exact dimensions. Their expertise minimizes defects.

Advanced Injection Molding for Medical Parts

Injection molding is ideal for small medical parts. The process allows high precision. It also supports complex designs.

An injection mould company uses cutting-edge machines. These machines maintain tight tolerances. The process produces identical parts in every cycle. Consistency is key in medical applications.

The Role of Skilled Mold Makers

Mold makers play a vital role. They create molds that shape medical parts. This work requires exceptional skill.

Medical parts often have intricate designs. Molds must capture every detail. Mold makers use advanced tools to achieve this. They also ensure molds are durable. This durability supports long production runs.

Material Selection for Medical Parts

Choosing the right material is critical. Medical parts must meet specific requirements. These include biocompatibility, strength, and heat resistance.

An injection mould company provides guidance. They recommend materials suited to the application. For example, they suggest flexible plastics for tubing. They use strong materials for surgical instruments. Their expertise ensures parts meet safety standards.

Custom Injection Molds for Complex Designs

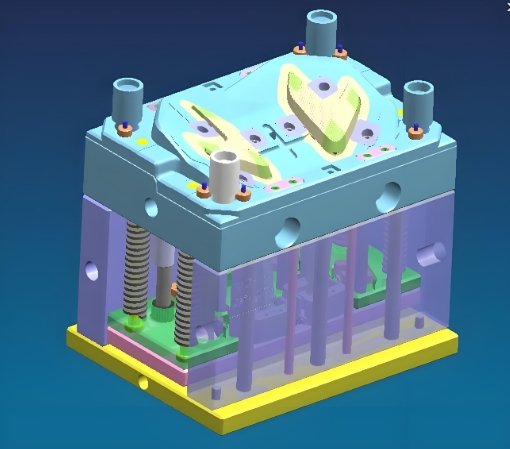

Small medical parts often have unique designs. Standard molds cannot handle these needs. An injection mould company creates custom injection molds.

Custom molds accommodate intricate geometries. They also support multi-material components. This flexibility is crucial for innovative medical devices.

Meeting Regulatory Standards

The medical industry has strict regulations. Every part must comply with these standards. An injection mould company ensures compliance.

They follow ISO and FDA guidelines. Their quality control processes are rigorous. This attention to detail prevents regulatory issues.

Fast Prototyping for Medical R&D

Medical device development moves quickly. Prototypes help refine designs. An injection mould company delivers fast prototyping solutions.

Using injection molding, they create accurate prototypes. These prototypes allow early testing. Design flaws are identified and fixed. This process speeds up product development.

Reducing Costs in Production

Medical parts often have high production volumes. Cost efficiency is crucial. An injection mould company optimizes costs.

They use efficient injection molding processes. Their expertise reduces material waste. Durable molds lower long-term production expenses. These savings benefit manufacturers and healthcare providers.

Ensuring Sterility in Production

Medical parts require sterile conditions. An injection mould company maintains strict hygiene.

Their facilities meet cleanroom standards. They use materials safe for sterilization. These measures protect patients from contamination.

Sustainability in Medical Injection Molding

Sustainability is a growing concern. An injection mould company supports eco-friendly practices.

They use recyclable plastics when possible. Energy-efficient machines reduce carbon footprints. These efforts align with healthcare sustainability goals.

Collaborating with Medical Innovators

Medical innovation requires collaboration. An injection mould company works closely with designers and engineers.

Their expertise refines concepts into manufacturable designs. They also provide feedback on feasibility. This partnership drives innovation in medical devices.

Applications of Injection Molding in Medicine

Injection molding supports various medical applications. It creates components for diagnostics, treatment, and surgery.

Examples include:

- Syringe barrels for precise dosing

- Catheters for patient care

- Diagnostic connectors for accurate readings

- Surgical guides for safe operations

Each part meets exact specifications.

Challenges and Solutions in Medical Injection Molding

Producing small medical parts has challenges. These include maintaining precision and meeting regulations. An injection mould company overcomes these obstacles.

They use advanced machines for accuracy. Their quality control ensures compliance. Skilled mold makers create reliable molds. These solutions guarantee success.

The Future of Medical Injection Molding

The future holds exciting possibilities. Advanced injection molding will support smarter medical devices. Automation will improve efficiency. Sustainable materials will become more common.

An injection mould company will remain essential. Their expertise will drive innovation and reliability.

Small medical parts require precision and reliability. An injection mould company delivers these qualities.

Their expertise in injection molding ensures accuracy. Skilled mold makers create high-quality injection molds. They also help meet regulatory standards.

Collaboration and innovation drive their success. For medical device manufacturers, they are a valuable partner. Choose an experienced injection mould company for your next project. Their solutions will enhance patient care and safety.