Lightweight materials dominate the automotive industry. Reducing vehicle weight improves fuel efficiency. It also enhances performance and reduces emissions. An Injection Mould Company plays a vital role in this process.

1. Why Lightweight Parts Matter

Modern cars need lightweight parts. Lower weight increases speed and reduces fuel use. Safety features also improve with advanced materials. Plastic parts offer the perfect solution. They are durable, flexible, and light.

2. Role of Injection Molding

Injection Molding is essential for automotive parts. It creates strong, precise components. The process ensures consistent quality. Advanced techniques optimize material use. This minimizes waste while maintaining strength.

3. Importance of a Skilled Mold Maker

The Mold Maker ensures precision. High-quality molds deliver accurate results. A skilled Mold Maker designs molds to handle complex shapes. This is critical for automotive applications.

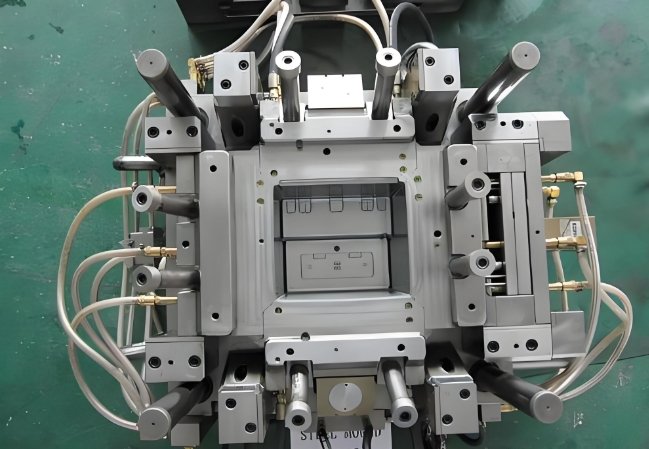

4. Injection Molds for Lightweight Parts

Durable Injection Molds are vital. They create thin but strong components. Automotive parts need high tolerances. Good molds ensure consistent thickness. This keeps parts lightweight without losing strength.

5. Material Selection for Automotive Parts

Plastic choices affect part weight. Common options include polypropylene, ABS, and polycarbonate. These materials combine strength with low density. Some plastics include reinforced fibers. These add strength without adding much weight.

6. Specialized Designs for Efficiency

Lightweight designs reduce material use. Engineers focus on minimizing excess. Ribbing and hollow sections keep parts strong. An Injection Mould Company ensures the design fits manufacturing needs.

7. Advanced Mold Design

Modern molds handle intricate designs. Cooling channels improve production speed. High-quality molds reduce defects. The right mold improves durability and consistency.

8. Challenges in Lightweight Parts Production

Lightweight parts require precision. Thin sections risk warping. Proper mold design prevents this. Temperature control ensures uniform cooling. Advanced techniques solve production issues.

9. Support from Injection Mould Companies

An Injection Mould Company offers expertise. They understand automotive needs. Custom solutions meet specific requirements. Their support streamlines production.

10. Quality Control Measures

Quality matters in automotive parts. Testing ensures durability and accuracy. Mold testing identifies design flaws early. Continuous inspection guarantees consistency.

11. Sustainability in Automotive Manufacturing

Sustainability drives lightweight designs. Less material use reduces waste. Recycled plastics support eco-friendly production. An Injection Mould Company prioritizes sustainable practices.

12. Applications in Automotive Parts

Lightweight parts are everywhere in cars. Examples include bumpers, dashboards, and panels. Engine components also use lightweight materials. Every part contributes to improved performance.

13. Advantages for Manufacturers

Lightweight parts offer many benefits. Production costs decrease with less material. Lighter vehicles meet emissions regulations. Improved fuel efficiency appeals to customers.

14. Innovations in Injection Molding

New techniques enhance Injection Molding. Microcellular foaming reduces part weight. Multi-material molding combines different plastics. These innovations support lightweight designs.

15. Choosing the Right Injection Mould Company

Pick an experienced Injection Mould Company. Check their expertise in automotive parts. Ensure they use advanced molding equipment. Skilled Mold Makers are a must.

16. Future of Lightweight Automotive Parts

Demand for lightweight parts will grow. Electric vehicles need durable, light components. Innovations in materials will drive progress. The role of Injection Mould Companies will expand.

Lightweight automotive parts depend on expert production. An experienced Injection Mould Company delivers high-quality results. Skilled Mold Makers craft durable Injection Molds. Their support ensures precision and efficiency. By choosing the right partner, manufacturers can meet evolving automotive demands.