Technology evolves rapidly. One major advancement is integrating AI with Rapid Prototyping. This combination transforms how products are developed. AI improves speed, precision, and creativity. Partnering with an expert Injection Mould Company ensures maximum benefits.

This article explores the powerful connection between AI and prototyping.

The Basics of AI in Prototyping

What Is AI?

AI stands for Artificial Intelligence. It enables machines to learn and make decisions.

What Is Rapid Prototyping?

Rapid Prototyping creates models quickly for testing. It’s essential for product design.

How AI Fits In

AI automates complex tasks. It analyzes data and predicts outcomes.

Advantages of AI in Rapid Prototyping

Faster Processes

AI reduces design time. It optimizes workflows.

Improved Precision

AI detects errors early. This minimizes waste.

Enhanced Creativity

AI generates innovative ideas. Designers can explore new possibilities.

Cost Efficiency

AI reduces material use. It optimizes machine operations.

Role of the Injection Mould Company

Partnering for Success

An Injection Mould Company bridges the gap between design and production.

AI-Driven Collaboration

The right company uses AI tools. They offer smarter prototyping solutions.

Material Optimization

AI helps the company suggest better materials.

AI Applications in Rapid Prototyping

3D Printing

AI improves printing speed and accuracy.

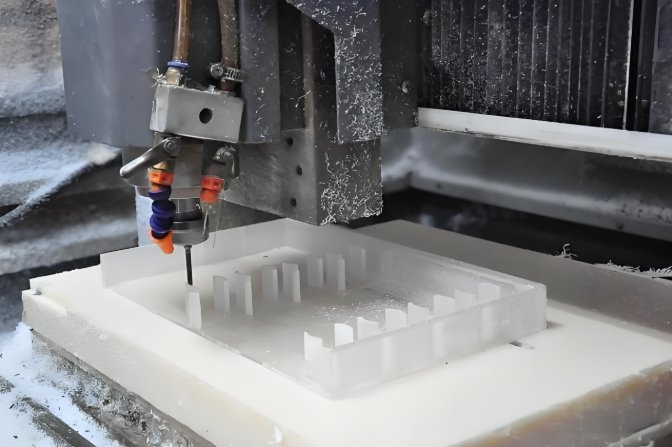

CNC Machining

AI ensures flawless cuts. It reduces setup time.

Injection Molding

AI predicts mold behavior. This enhances efficiency.

AI in Design Stages

Idea Generation

AI suggests new concepts. It uses past data for inspiration.

Design Optimization

AI refines designs automatically. It ensures functionality and aesthetics.

Virtual Testing

AI simulates performance. Designers fix problems before production.

AI in Manufacturing

Real-Time Monitoring

AI tracks machines during production. This avoids delays.

Predictive Maintenance

AI predicts equipment failures. Downtime is minimized.

Quality Control

AI inspects prototypes. It detects imperfections instantly.

Challenges in AI Integration

High Costs

AI tools are expensive initially.

Learning Curve

Teams need training to use AI effectively.

Compatibility Issues

Old systems may not support AI technologies.

Overcoming Challenges

Strategic Investment

Start with essential AI tools. Expand gradually.

Training Programs

Offer workshops to employees.

Expert Partnerships

Collaborate with an advanced Injection Mould Company.

Success Stories

AI Enhances Speed

A company cut prototyping time by 50% using AI.

Precision at Its Best

Another firm reduced defects by 30% with AI tools.

Cost Savings Achieved

AI helped save thousands in material costs.

Future of AI and Rapid Prototyping

Smarter Algorithms

AI will become even more intelligent.

Autonomous Machines

Prototyping will require minimal human intervention.

Sustainable Solutions

AI will prioritize eco-friendly practices.

Why Choose the Right Injection Mould Company

AI Integration Expertise

The best companies already use AI technologies.

Cost Efficiency

They ensure affordable prototyping with advanced tools.

Quality Assurance

Expect flawless prototypes every time.

Final Thoughts

AI reshapes Rapid Prototyping. It streamlines processes, enhances creativity, and reduces costs. The right Injection Mould Company makes this integration seamless.

Invest in AI and expert partnerships. Unlock the future of product innovation.