When choosing an injection mould company, it’s important to understand the key differences between them. Injection molding is a specialized process that requires a high level of expertise. Each mold maker brings a unique set of skills, equipment, and technologies to the table. These factors can have a major impact on your project’s success. Let’s explore what sets different injection mould companies apart.

1. Experience and Expertise

One of the most significant factors in choosing an injection mould company is its experience. Companies with years of experience tend to have a better understanding of injection molding techniques. This experience often leads to more efficient processes and fewer errors.

An experienced mold maker will know how to create precise injection molds that can withstand the pressures of high-volume production. They’ll also be able to anticipate potential issues and come up with solutions quickly. More experienced companies may offer a wider range of services, such as custom designs or advanced molding technologies.

2. Technology and Equipment

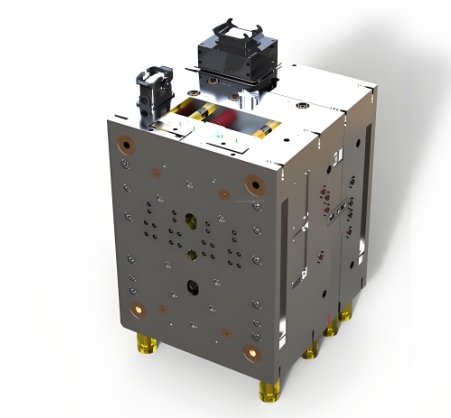

Different injection mould companies use different technologies and equipment. The quality of the injection molds they produce largely depends on the equipment they use. Some companies may have state-of-the-art machinery, while others may rely on older models. Companies that invest in new technologies can often provide faster and more accurate production.

For example, newer injection molding machines are designed to improve energy efficiency and reduce production time. Some companies may also have robotic systems in place to automate the molding process. This can reduce labor costs and improve the overall speed and accuracy of production.

3. Customization and Flexibility

Some injection mould companies specialize in highly customized solutions, while others focus on mass production. If your project requires a mold maker who can handle unique or complex designs, you’ll need a company with a high level of flexibility. These companies often have experience working with various materials and adapting to specific client needs.

Flexibility is especially important for businesses that require prototypes or low-volume production runs. Many companies that offer customization also provide rapid prototyping services, allowing you to test your design before full-scale production begins.

4. Quality Control Standards

Quality control is critical in injection molding. Companies with stringent quality control measures ensure that every injection mold produced meets the highest standards. Look for companies that use advanced inspection equipment, such as 3D scanners, to check the dimensions and surface quality of the molds.

In addition to dimensional accuracy, a reliable injection mould company will also ensure that the molds are free from defects. This helps minimize errors during the production process and ensures a high-quality end product. Consistent quality control is particularly important for industries with strict regulations, such as automotive or medical device manufacturing.

5. Lead Time and Production Speed

Time is money. In today’s competitive market, it’s essential to partner with a company that can deliver your molds on time. Some injection mould companies specialize in fast turnaround times, making them ideal for clients who need products quickly. Others may have longer lead times but offer more specialized or complex mold-making services.

The ability to scale production quickly is also a key factor to consider. Some companies may have the capacity to handle large orders, while others may be better suited to small batch production. Understanding the injection molding company’s lead time and production speed can help you plan your project timeline more effectively.

6. Customer Support and Communication

Customer support is often overlooked, but it plays a crucial role in the success of any project. A good mold maker will provide clear communication throughout the entire process. From initial design to the final product, consistent updates and open channels of communication can help avoid misunderstandings.

A responsive customer service team can also help resolve any issues quickly. Whether it’s a design change or a production delay, effective communication ensures that your project stays on track. Companies with a focus on customer satisfaction tend to be more reliable and easier to work with in the long run.

7. Cost Efficiency

Cost is always a consideration when choosing an injection mould company. While some companies may offer lower prices, it’s important to consider the value you’re getting for your money. Cutting costs can sometimes mean compromising on quality, so it’s essential to find a balance between affordability and reliability.

A reputable mold maker will provide you with a clear breakdown of the costs involved in your project. This allows you to compare different companies and choose the one that offers the best value. In some cases, higher upfront costs may result in lower long-term production costs due to better quality and fewer defects.

8. Material Expertise

Different injection mould companies may specialize in different types of materials. Some companies may have expertise in working with metals, while others may specialize in plastics, rubbers, or composites. Understanding the material expertise of a company is critical to ensure they can meet your specific requirements.

For example, if you’re producing automotive parts, you’ll need a mold maker who understands the unique properties of materials like thermoplastics or reinforced polymers. Companies with expertise in your specific material can provide better advice and produce more reliable molds.

9. Sustainability and Environmental Responsibility

In today’s world, sustainability is a growing concern for many businesses. Some injection mould companies are more focused on environmentally friendly practices than others. Companies that prioritize sustainability may use eco-friendly materials, reduce waste, and implement energy-saving technologies in their production process.

If sustainability is important to your business, look for companies that have adopted green manufacturing practices. This can include using recyclable materials, reducing emissions, and using energy-efficient machinery.

10. Industry Specialization

Finally, some injection mould companies specialize in specific industries, such as automotive, medical, or consumer goods. These companies may have specialized knowledge and experience in dealing with the unique challenges and regulations of these industries.

For example, medical device manufacturers require extremely precise and high-quality molds, while automotive companies may need molds for large, complex parts. A mold maker with expertise in your industry can help you navigate these challenges and ensure the success of your project.

Conclusion

The differences between injection mould companies are vast. From their expertise in materials and technologies to their approach to quality control and customer service, every company brings something unique to the table. When selecting a company for your project, consider factors like experience, customization capabilities, lead time, and cost efficiency.

By understanding these key differences, you can choose the right mold maker and injection mould company to meet your specific needs. Whether you’re working on a complex design or need a fast turnaround, selecting the right partner is crucial to the success of your project.