High-volume projects require specialized attention and advanced capabilities. Working with an experienced injection mould company can make a huge difference. These companies provide a range of services tailored to large-scale production. They help ensure that injection molding processes are efficient, precise, and cost-effective.

When it comes to high-volume production, an experienced mold maker is crucial. They know how to design and build molds that last. They also ensure the molds work perfectly every time. An injection mould company brings the skills, technology, and knowledge needed to support high-volume production.

Expert Design and Prototyping

An injection mould company starts with designing the right molds. This is a key step in the injection molding process. The design must meet the specifications of the product, including shape, size, and material. It must also account for the number of units needed for the high-volume order. A skilled mold maker uses advanced software to create a 3D model of the mold. This helps to predict any issues before production begins. Prototypes are often made first to test the design. The injection mould company will adjust the design based on feedback and testing.

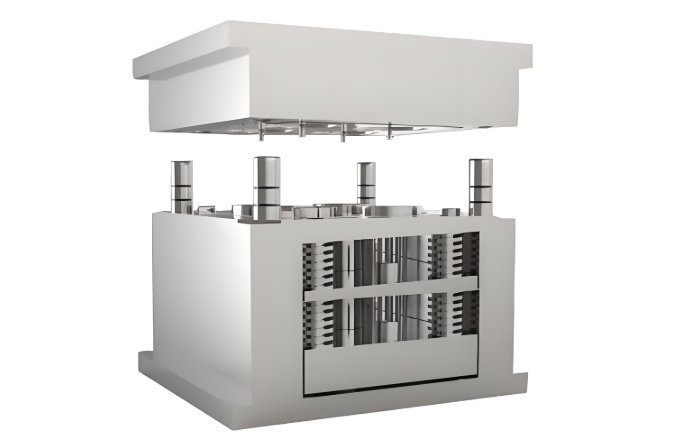

Mold Construction

The mold maker is responsible for building the actual molds used in production. They use precision machining and high-quality materials to ensure the molds are durable. The injection mould must withstand repeated use during high-volume production. A poor-quality mold can lead to defects in the finished products. A good mold maker knows how to create molds that will last, even under heavy use. The injection mould company ensures that every mold is tested for quality before being used in production.

High-Volume Injection Molding

Once the molds are ready, the injection molding process begins. High-volume injection molding requires fast, efficient production. The injection mould company uses advanced machines to inject molten plastic into the molds. This process is repeated thousands, even millions, of times. Each time, the mold must maintain its shape and precision. The injection mould company ensures that the process runs smoothly by carefully managing the equipment and material flow.

Materials Selection

For high-volume projects, choosing the right material is crucial. An injection mould company helps clients select the best material for their needs. This decision depends on the product’s function, appearance, and cost. A skilled mold maker can recommend materials that will provide the best results for both quality and budget. The company also ensures that the material used is suitable for high-volume production. Some materials may perform better under high heat or stress, making them ideal for certain products.

Quality Control

Quality control is a key service offered by any injection mould company. With high-volume projects, it is vital to ensure that every product meets the required standards. The injection mould company uses various testing methods to check for defects. These tests include visual inspections, measurements, and performance testing. Any products that fail to meet the specifications are removed before they reach the customer. This helps ensure that only high-quality products are delivered.

Fast Turnaround Times

One of the main advantages of working with an injection mould company is the speed of production. For high-volume projects, quick turnaround times are essential. The injection mould company uses advanced technology and efficient processes to shorten production times. With experienced engineers and technicians, they ensure that molds are ready quickly and production starts on schedule. A skilled mold maker also contributes to faster turnaround by designing molds that are easy to manufacture and use.

Cost Efficiency

High-volume production is all about cost efficiency. An injection mould company works hard to keep costs low while maintaining high quality. By optimizing the mold design and injection molding process, they can reduce waste and improve productivity. This helps lower production costs for large orders. The injection mould company also ensures that the molds are built to last, reducing the need for costly replacements. Additionally, they often have the ability to scale up production quickly, ensuring that clients get the best price for their project.

Customization and Flexibility

Each high-volume project is different. An injection mould company offers customized solutions for each client. The mold maker works with the client to understand their needs and design molds accordingly. This allows for flexibility in the design and manufacturing process. Whether the client needs special features, unique shapes, or specific material properties, the injection mould company can accommodate these requests. Customization ensures that the end product meets the client’s exact specifications.

Maintenance and Repair Services

Over time, even the best molds may need maintenance or repair. An injection mould company offers maintenance services to keep molds in good condition. This is especially important for high-volume production, where molds are used repeatedly. Regular maintenance helps extend the life of the mold and ensures consistent production quality. In the event of damage or wear, the mold maker can perform repairs quickly to minimize downtime.

Post-Production Support

Once the products are molded, there are still many steps to complete. The injection mould company often provides post-production services, such as assembly, packaging, and shipping. This is particularly helpful for clients who want a one-stop solution for their high-volume projects. The company can handle all aspects of production, from the initial design to the final product delivery. This level of support reduces the need for clients to coordinate with multiple suppliers, saving time and effort.

Collaboration with Clients

A strong partnership between the client and the injection mould company is essential for the success of high-volume projects. Communication is key. The mold maker works closely with the client to ensure the project moves forward smoothly. From the initial design stage to final delivery, the injection mould company keeps the client informed and involved. This collaboration helps to avoid misunderstandings and ensures that the final product meets all expectations.

Advantages of Working with an Injection Mould Company

Working with a skilled injection mould company offers many benefits for high-volume projects. They provide expertise in injection molding, helping to ensure that products are made efficiently and to the highest standards. By choosing the right mold maker, companies can save time and reduce costs. The ability to produce large quantities quickly and with consistent quality is a major advantage of working with an experienced injection mould company. Additionally, the customization options and flexibility make it easier to meet unique project requirements.

For high-volume projects, working with an experienced injection mould company is essential. These companies offer a wide range of services, from mold design and construction to quality control and post-production support. By partnering with a skilled mold maker, clients can ensure that their high-volume projects are completed on time, within budget, and to the highest standards. Whether it’s injection molding, material selection, or mold maintenance, an injection mould company provides the expertise needed for successful large-scale production.