Medical devices require high precision and sterility. Medical injection molding meets these demands. Cleanroom manufacturing plays a key role. It ensures contamination-free production. Mold makers design precise molds for these environments.

What is Cleanroom Manufacturing?

1. Definition

Cleanroom manufacturing takes place in a controlled environment. Airborne particles, humidity, and temperature are regulated.

2. Purpose

It prevents contamination in medical injection molding. This ensures product safety.

3. Importance in Medical Devices

Medical products must meet strict hygiene standards. Cleanrooms help achieve this.

Cleanroom Standards for Medical Injection Molding

1. ISO Classifications

Cleanrooms follow ISO standards. The most common are:

- ISO 8: 3,520,000 particles per cubic meter

- ISO 7: 352,000 particles per cubic meter

- ISO 6: 35,200 particles per cubic meter

2. FDA Compliance

Devices must meet FDA cleanliness requirements.

3. Sterilization Protocols

Strict rules ensure product sterility.

Benefits of Cleanroom Medical Injection Molding

1. Contamination Prevention

Cleanrooms keep bacteria and dust away.

2. Consistent Quality

Controlled environments reduce defects.

3. Regulatory Compliance

Products meet FDA and ISO standards.

4. Safer Medical Devices

Sterile manufacturing protects patients.

5. Increased Production Efficiency

Fewer defects mean faster production.

Applications of Cleanroom Medical Injection Molding

1. Surgical Instruments

Precision molding ensures safe tools.

2. Drug Delivery Systems

Cleanrooms prevent contamination in inhalers and syringes.

3. Implantable Devices

Sterile production protects implants from bacteria.

4. Diagnostic Equipment

High-precision parts improve testing accuracy.

5. IV Components

Tubes and connectors require sterile manufacturing.

How Mold Makers Support Cleanroom Manufacturing

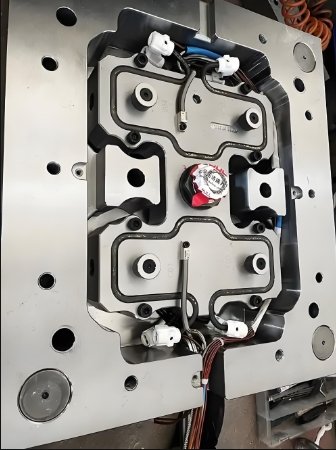

1. Designing Precision Molds

They create molds for strict hygiene requirements.

2. Using Medical-Grade Materials

Only approved plastics are used.

3. Ensuring Mold Cleanliness

Molds undergo strict cleaning processes.

4. Optimizing Injection Molding Cycles

They design molds for faster, defect-free production.

Key Equipment in Cleanroom Injection Molding

1. HEPA Filters

They remove airborne particles.

2. Sealed Molding Machines

Machines prevent contamination.

3. Antistatic Systems

These reduce dust attraction.

4. Automated Handling Systems

Less human contact minimizes contamination risks.

Challenges in Cleanroom Medical Injection Molding

1. High Setup Costs

Cleanrooms require advanced technology.

2. Strict Maintenance

Facilities must stay contamination-free.

3. Limited Material Choices

Only FDA-approved plastics are allowed.

4. Higher Energy Consumption

Air filtration systems increase power use.

Future of Cleanroom Medical Injection Molding

1. Automation Growth

More robots reduce contamination risks.

2. Smart Cleanrooms

Sensors monitor air quality in real-time.

3. Sustainable Manufacturing

Eco-friendly materials will reduce waste.

Cleanroom environments ensure safe medical injection molding. Mold makers design high-precision molds for sterile production. This process guarantees high-quality, contamination-free medical devices.