Innovation drives medical technology. Medical injection molding plays a key role. Mold makers create high-precision components. Many companies succeed with this technology. These stories show how.

1. How Medical Injection Molding Transforms Healthcare

1.1 High Precision Manufacturing

- Produces complex medical parts.

- Ensures accuracy and consistency.

- Reduces defects and errors.

1.2 Cost-Effective Production

- Reduces material waste.

- Supports high-volume manufacturing.

- Saves money without sacrificing quality.

1.3 Meeting Strict Medical Standards

- FDA and ISO compliant.

- Supports sterilization requirements.

- Ensures patient safety.

2. Leading Companies in Medical Injection Molding

2.1 Company A: Revolutionizing Diabetes Care

- Specializes in insulin pens.

- Uses medical injection molding for precise components.

- Ensures accurate insulin dosing for patients.

2.2 Company B: Advanced Surgical Instruments

- Produces high-precision scalpels and forceps.

- Uses mold makers for detailed designs.

- Guarantees sharp, reliable instruments.

2.3 Company C: Disposable Medical Supplies

- Manufactures syringes and IV components.

- Uses high-speed injection molding.

- Meets global healthcare demands.

3. Success in Medical Device Manufacturing

3.1 Case Study: Improved Pacemaker Casings

- Needed lightweight, durable materials.

- Switched to medical injection molding.

- Reduced weight and increased biocompatibility.

3.2 Case Study: Efficient COVID-19 Test Kits

- Demand surged for rapid tests.

- Mold makers helped scale production.

- Millions of kits were delivered globally.

3.3 Case Study: Smart Wearable Devices

- Developed heart monitors and glucose sensors.

- Used injection molding for lightweight parts.

- Enhanced patient comfort and usability.

4. Key Technologies in Medical Injection Molding

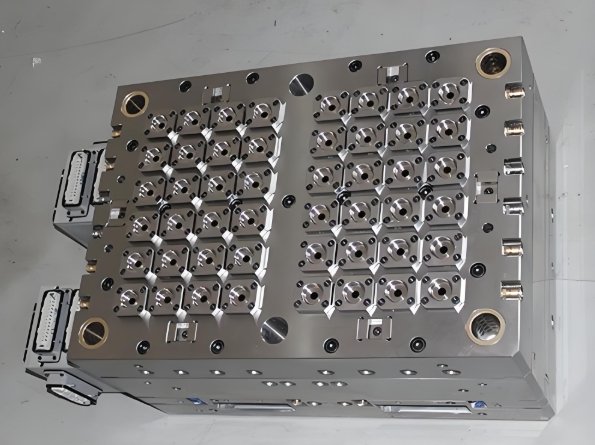

4.1 Multi-Cavity Molds

- Increases production efficiency.

- Reduces manufacturing time.

- Supports mass production of medical devices.

4.2 Micro Molding for Small Parts

- Used for tiny medical components.

- Ensures high precision and consistency.

- Critical for implantable devices.

4.3 Overmolding for Hybrid Products

- Combines materials for better functionality.

- Improves grip, durability, and strength.

- Used in surgical tools and diagnostic devices.

5. Role of Mold Makers in These Success Stories

5.1 Precision Engineering

- Designs highly accurate molds.

- Supports complex medical components.

- Ensures smooth production processes.

5.2 Material Selection Expertise

- Uses biocompatible plastics.

- Selects materials for sterilization compatibility.

- Enhances product safety and durability.

5.3 Continuous Quality Control

- Ensures zero defects in production.

- Uses automated inspection systems.

- Meets strict medical regulations.

6. The Future of Medical Injection Molding

6.1 Growth of Smart Medical Devices

- More wearable health monitors.

- Injection molding enables miniaturization.

- Supports advanced medical electronics.

6.2 Sustainable Manufacturing Trends

- Development of biodegradable plastics.

- Reducing waste in medical production.

- Meeting eco-friendly goals.

6.3 AI and Automation in Molding

- Improves production speed and accuracy.

- Reduces manual labor costs.

- Enhances real-time quality control.

Top companies use medical injection molding for innovation. Mold makers ensure high precision. This technology continues to advance. It improves healthcare worldwide.