Automotive

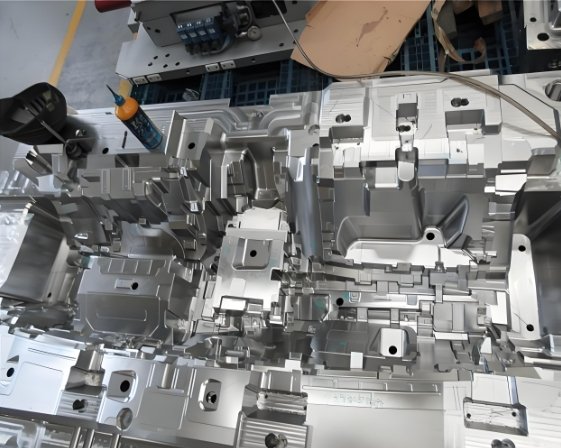

Mold Maker:Injection molding is widely used in the automotive industry due to its efficiency and ability to produce complex parts with high precision. Here’s a broad list of automotive components commonly made using injection molding by a skilled.

Bumpers

Bumpers: The Injection Mould Company utilizes injection molding to produce the outer shells and some internal components of bumpers. This process is favored because of the material’s ability to absorb impact and be formed into complex shapes.

Dashboard Panels

Dashboard Panels: Dashboard panels are crafted by an Injection Mould Company from plastic materials that are molded to provide a precise fit and a smooth surface finish.

Interior Trim

Interior Trim: Various interior trim components, such as center consoles, door panels, and instrument cluster bezels, are manufactured using injection molding by The Injection Mould Company due to their intricate designs and surface finish requirements.

Grilles

Grilles: Front grilles are often molded by The Injection Mould Company to achieve the specific shapes and fine details required for aesthetic and functional purposes.

Insights From The Mold Maker

Headlight and Taillight Housings

Headlight and Taillight Housings: The Injection Mould Company uses injection molding to produce complex shapes and clear lenses for headlight and taillight housings.

Mirror Housings

Mirror Housings: The housings for side mirrors are molded byThe Injection Mould Company to precise specifications to ensure proper fit and durability.

Tips From The Mold Maker

Air Intake Manifolds

Air Intake Manifolds: Some air intake manifolds are made by The Injection Mould Company from high-performance plastics to reduce weight and improve fuel efficiency.

Engine Covers

Engine Covers: The Injection Mould Company uses injection molding to produce lightweight and durable engine covers that can withstand high temperatures and mechanical stress.

Insights From The Mold Maker

Seat Components

Seat Components: Various components of vehicle seats, including backrests, seat bases, and trim pieces, are made by using injection molding for their comfort and ergonomic design.

Fuel Tank Parts

Fuel Tank Parts: Certain parts of the fuel tank assembly, such as connectors and caps, are produced by using injection molding for their precision and chemical resistance.

Tips From The Mold Maker

Weatherstripping Clips

Weatherstripping Clips: Clips and fasteners used for securing weatherstripping and trim pieces are produced by using injection molding for their consistency and ease of installation.

Injection molding is chosen for these parts due to its ability to produce high volumes of parts with tight tolerances, complex geometries, and excellent surface finishes, all while being cost-effective. The Injection Mould Company plays a crucial role in ensuring the quality and precision of these automotive components.