Mold Maker In Construction

Injection molding is a crucial process in the construction industry, allowing for the production of durable, complex, and cost-effective components. Construction projects demand materials that can withstand heavy use and harsh conditions. As a leading Mold Maker we understand how injection molding meets these requirements efficiently, making it the preferred method for producing various construction parts.

Fasteners and Connectors:

Examples: Wall anchors, spacers, clips, and brackets.

Wall anchors, spacers, clips, and brackets are essential for secure connections in construction. Injection molding enables the mass production of these parts with precision and at a low cost, ensuring consistent quality. As a trusted mold maker, we ensure that every component meets strict industry standards

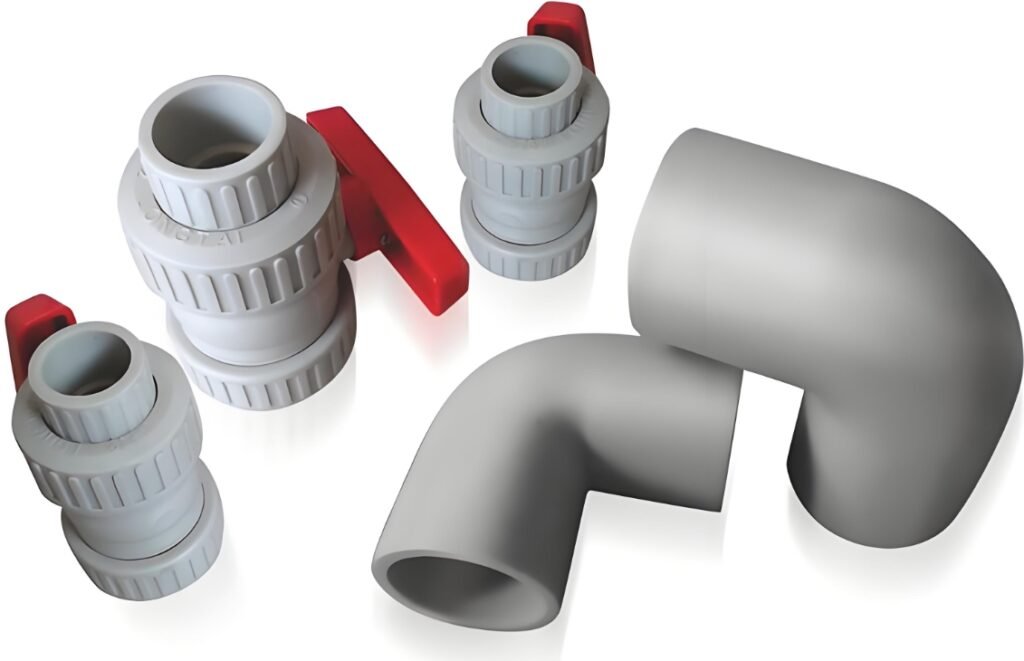

Pipe Fittings and Joints:

Advices from Injection Mould Company

Examples: Elbows, tees, couplings, and valves.

Injection molding produces high-quality fittings with intricate shapes, ensuring a proper seal and long-lasting durability. Our injection mould company specializes in creating these critical components.

Insulation Components

Examples: Insulation supports, panels, and foam boards.

Injection-molded insulation components are lightweight and easy to install, which is highly beneficial in construction. Our expertise as a mold maker ensures these parts meet the highest standards for efficiency and performance.

Concrete Formwork and Molds:

Tips from Injection Mould Company

Examples: Reusable plastic formwork, interlocking blocks, and decorative concrete molds.

These components are lightweight, easy to handle, and offer precise shapes, making them a superior alternative to traditional wooden or metal forms. Our injection mould company delivers these innovative solutions to enhance construction processes.

Roofing Components:

Advices from Injection Mould Company

Examples: Roofing tiles, vents, and flashing.

Injection molding produces these parts with consistent quality, simplifying both installation and maintenance. As a leading mold maker, we ensure these components meet all construction industry standards

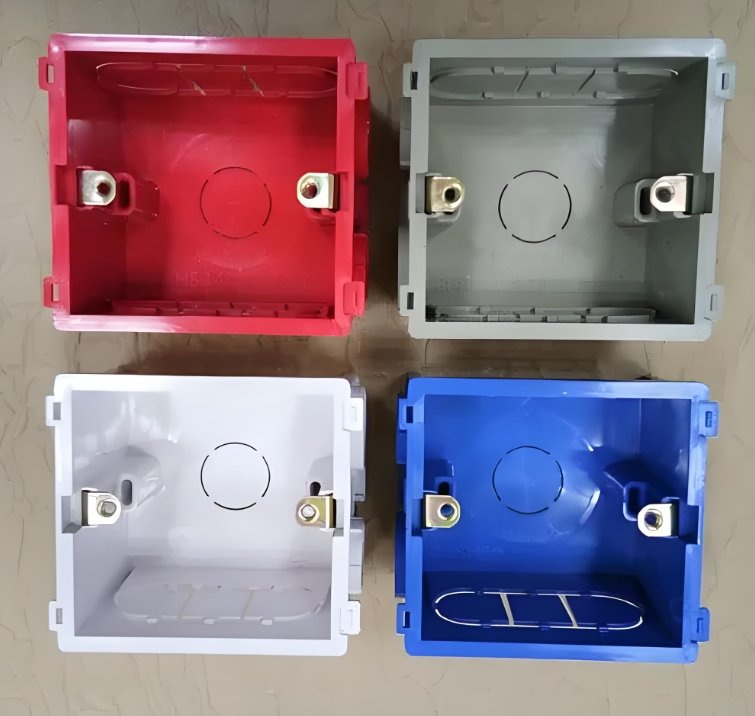

Electrical and Conduit Fittings:

Tips from Injection Mould Company

Examples: Junction boxes, conduit elbows, and cable management systems.

Safety and reliability are critical in electrical systems. Injection-molded components provide the necessary insulation, durability, and fire resistance, ensuring long-lasting performance in construction projects.

Window and Door Components:

Advices from Injection Mould Company

Examples: Frames, seals, gaskets, and handles.

Precision and durability are essential for window and door components to ensure proper insulation and security. Injection molding produces parts that fit perfectly and can be customized to various designs and specifications.

Advantages of Injection Molding in the Construction Sector

Durability and Weather Resistance: Injection-molded parts can be made from high-performance plastics that resist moisture, UV radiation, and extreme temperatures, making them ideal for outdoor applications.

Cost-Effectiveness: For high-volume production, injection molding offers a low cost per part, making it economically viable for producing the vast quantities of components needed in construction.

Versatility: Injection molding supports a wide range of materials, including reinforced plastics and composites, allowing for the production of parts that meet specific mechanical and aesthetic requirements.

Complex Geometries: The ability to produce intricate designs and complex shapes with consistent quality is a significant advantage in construction, where custom and precise parts are often required.

Lightweight: Injection-molded components are typically lighter than metal or concrete alternatives, reducing transportation costs and making handling easier on construction sites.

As an experienced mold maker and injection mould company, we ensure that our injection-molded components meet the highest industry standards. Using injection molding in construction allows for the efficient production of high-quality parts essential for building strong, energy-efficient, and visually appealing structures.