Mold Maker :Dimensional Inspection and Tolerance Analysis

In mold manufacturing, dimensional inspection and tolerance analysis are critical processes that ensure the final product meets the required specifications. The role of the mold maker in these processes is paramount, as their expertise directly impacts the precision and quality of the molds produced.

A skilled mold maker must maintain tight tolerances to avoid defects that could compromise the functionality or appearance of the molded parts.

Tolerance Analysis Is Important In Mold Maker

Tolerance analysis involves assessing how variations in manufacturing processes could impact the final product’s dimensions. A proficient Injustion Mould Company uses tolerance analysis to predict potential dimensional issues and make necessary adjustments to the mold design or manufacturing process.

By doing so, the injection mould company ensures that the mold will produce parts within the acceptable tolerance range, thereby reducing the risk of defects and the need for costly rework.

Dimensional inspection is the process of measuring the actual dimensions of the mold and the parts it produces. This step is crucial for verifying that the mold is manufactured according to the design specifications.

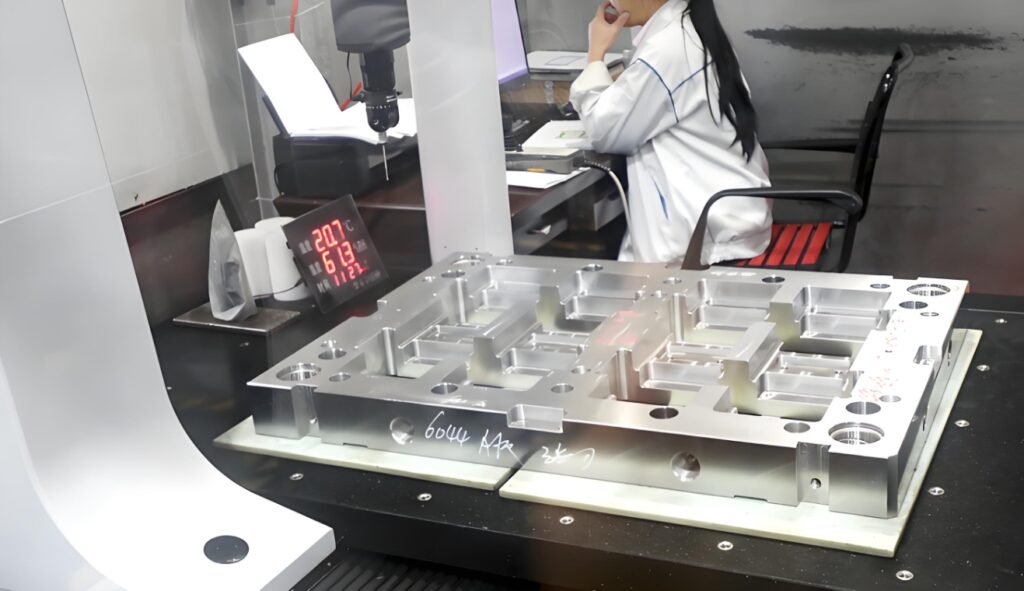

The injection mould company employs various measurement techniques, such as coordinate measuring machines (CMMs), laser scanners, or optical comparators, to conduct these inspections. These tools allow An Injection Mould Company to ensure that both the mold and the molded parts meet the required dimensions.

Mesuring Machine

Material behavior during the molding process adds another layer of complexity to dimensional inspection. Different materials have varying shrinkage rates, which can affect the final dimensions of the molded part.

A knowledgeable mold maker understands these material properties and considers them during the design and inspection processes. By doing so, the mold maker can adjust the mold design to compensate for material variations, ensuring that the final product remains within the desired tolerances.

The Injection Mould Company is integral to the success of dimensional inspection and tolerance analysis in mold manufacturing. Their expertise ensures that molds are designed and produced to yield high-quality, dimensionally accurate parts.

Through careful tolerance analysis and precise dimensional inspection, the mold maker can minimize defects, reduce rework, and guarantee that the final products meet or exceed industry standards. The repeated attention to detail by the mold maker throughout the process is key to achieving the precision required in modern manufacturing.