Large-scale production in the automotive industry demands precision. High-quality Automotive Injection Molds play a critical role. Expert Mold Makers design molds for efficiency. This article explores how molds meet the needs of large-scale production.

Importance of Large-Scale Production

1. Demand for High Volumes

Automakers produce millions of vehicles yearly.

2. Cost-Effective Manufacturing

Efficiency lowers costs for mass production.

3. Consistent Quality

Parts must meet strict standards repeatedly.

4. Quick Turnaround

Fast production ensures timely vehicle delivery.

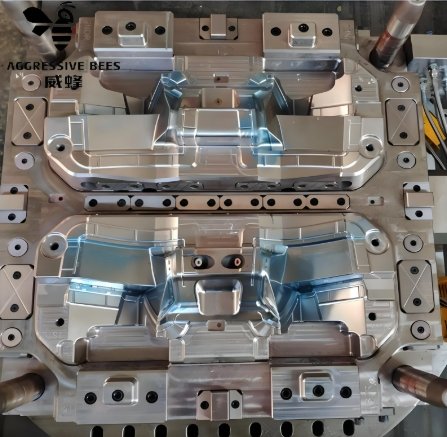

Role of Automotive Injection Molds

1. Precision Engineering

Molds ensure consistent part dimensions.

2. High Durability

They withstand high production cycles.

3. Customizable Designs

Molds cater to unique vehicle models.

4. Efficient Material Use

They minimize waste during production.

Key Applications in Automotive Manufacturing

1. Exterior Panels

Molds shape bumpers, doors, and fenders.

2. Interior Components

Dashboards, consoles, and trims rely on molds.

3. Engine Covers

Injection molds produce precise engine housings.

4. Lighting Systems

They create durable headlight and taillight parts.

Features of Optimized Molds

1. Multi-Cavity Design

Creates multiple parts in one cycle.

2. High-End Materials

Ensures molds last longer under stress.

3. Cooling Systems

Speeds up the production process.

4. Automated Features

Reduces human intervention and errors.

How Mold Makers Improve Efficiency

1. Advanced Technology

Mold Makers use CNC machines for precision.

2. Prototyping

Testing ensures molds meet design requirements.

3. Material Expertise

They select the right materials for strength.

4. Continuous Improvement

Regular upgrades keep molds efficient.

Challenges in Large-Scale Mold Production

1. Complex Designs

Unique parts require intricate molds.

2. Material Wear

High production cycles cause mold degradation.

3. Energy Consumption

Large-scale molding uses significant energy.

4. Time Constraints

Meeting deadlines can be challenging.

Solutions for Efficient Production

1. Use of Advanced Materials

Stronger materials extend mold life.

2. Improved Cooling Systems

Faster cooling reduces cycle times.

3. Automated Inspection

Ensures parts meet strict standards.

4. Collaborative Design

Engineers and Mold Makers work together.

Advantages of Optimized Injection Molds

1. Reduced Costs

Efficient molds lower production expenses.

2. Higher Speed

Mass production meets tight deadlines.

3. Better Quality Control

Consistent molds produce identical parts.

4. Environmental Benefits

Less waste and energy use support sustainability.

Innovations in Automotive Injection Molds

1. Smart Molds

Sensors monitor performance in real-time.

2. Multi-Material Molding

Combines materials in one part.

3. Recyclable Materials

Supports eco-friendly manufacturing.

4. 3D Printing Integration

Enhances prototyping and production.

Steps in Large-Scale Mold Production

1. Initial Design

Concept sketches define the mold.

2. Digital Modeling

3D models ensure accuracy.

3. Prototype Testing

Small-scale molds verify designs.

4. Mass Production

Final molds create thousands of parts.

Future Trends in Mold Manufacturing

1. Increased Automation

Robotics will boost speed and accuracy.

2. Sustainability Focus

Eco-friendly practices will dominate.

3. Advanced Materials

New materials will improve durability.

4. Customization at Scale

Tailored molds for niche markets.

Optimized Automotive Injection Molds are key to large-scale production. Skilled Mold Makers ensure precision and efficiency. With innovations in design and materials, molds continue to transform automotive manufacturing.