In the world of manufacturing, Injection Molding is a key process used to create high-quality parts for a variety of industries, from automotive to consumer goods. The success of this process relies heavily on the quality standards set by the Injection Mould Company. These standards ensure that the final product meets all the necessary specifications and functions as intended. Whether it’s for creating complex automotive parts or simple household items, the importance of precision in the molding process cannot be overstated.

An Injection Mould Company specializes in designing and manufacturing Injection Molds, which are the tools used to shape molten material into the desired form. A Mold Maker is responsible for creating these molds with high accuracy, ensuring that the products produced meet the tight tolerances required for specific applications. The process is intricate and requires a deep understanding of materials, machinery, and quality control standards.

The Role of Injection Molding in Manufacturing

Injection Molding is a widely used manufacturing process because of its ability to produce large quantities of parts with high precision and consistency. The process involves injecting molten material, such as plastic or metal, into a mold under high pressure. Once the material cools and solidifies, the mold is removed, leaving behind a perfectly shaped part. This process is repeated thousands of times for mass production.

The key to successful Injection Molding lies in the design and creation of the mold. A well-designed mold can help reduce defects, improve efficiency, and ensure that the final product is consistent. This is why the quality standards of an Injection Mould Company are so crucial.

How Mold Makers Ensure Quality in Injection Molds

Mold Makers are skilled professionals who craft the Injection Molds used in the Injection Molding process. Their role is crucial in ensuring that the molds are created with the precision required to produce high-quality parts. The process of creating a mold involves several important steps:

- Design and Prototyping: The first step in the mold-making process is to create a design based on the specifications of the part to be produced. Advanced computer-aided design (CAD) software is often used to create detailed designs, ensuring that the mold will meet the necessary tolerances. Once the design is completed, a prototype mold may be created to test for fit and functionality.

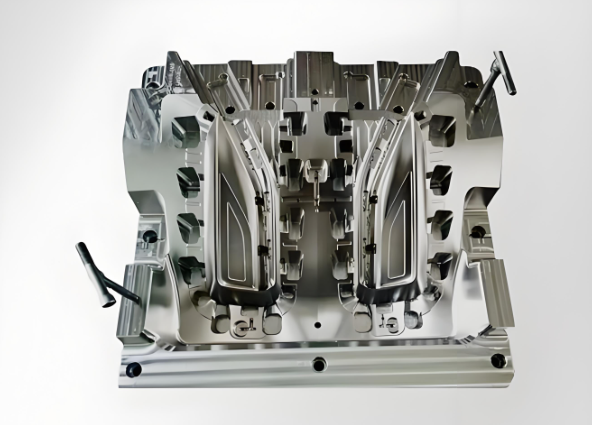

- Material Selection: Choosing the right materials for the mold is essential. The materials need to withstand the high temperatures and pressures of the Injection Molding process without warping or deteriorating. Common materials used for molds include steel and aluminum, both of which offer durability and strength.

- Precision Machining: Mold Makers use specialized equipment to machine the mold to the precise dimensions required. CNC machines, EDM (Electrical Discharge Machining), and other advanced tools are used to create the intricate features of the mold. Precision machining ensures that the mold is free of imperfections that could affect the final product.

- Assembly and Testing: After the mold is machined, it is assembled and tested to ensure that it functions as expected. The mold is fitted with cooling channels, ejection systems, and other necessary features. Testing is critical to ensure that the mold can withstand the demands of the Injection Molding process and produce parts with consistent quality.

- Quality Control: Quality control is a fundamental part of the mold-making process. Injection Mould Companies employ strict quality control measures to ensure that every mold produced meets the required specifications. This can involve dimensional checks, visual inspections, and sometimes even functional testing of the mold.

Why Injection Mould Company Quality Standards Matter

The quality standards set by an Injection Mould Company are essential for ensuring the precision and reliability of the molds it produces. These standards are not just about ensuring the molds are made to the correct dimensions, but also about guaranteeing that they can perform consistently over time. Here are some reasons why these quality standards are so important:

- Consistency: A key advantage of Injection Molding is the ability to produce large quantities of identical parts. For this to happen, the mold must be of the highest quality and precision. If the mold is not made to the correct specifications, the parts produced may vary in size, shape, or quality, which can lead to product defects and increased costs.

- Efficiency: High-quality molds improve the efficiency of the Injection Molding process. If a mold is poorly made, it can lead to production delays, waste, and higher energy consumption. A well-crafted mold, on the other hand, helps the manufacturing process run smoothly, reducing downtime and material waste.

- Durability: Molds are used repeatedly in the Injection Molding process, so they need to be durable and long-lasting. Poor-quality molds may wear out quickly, requiring frequent repairs or replacements. High-quality molds, made by skilled Mold Makers, have a longer lifespan, reducing maintenance costs and improving overall production efficiency.

- Cost-Effectiveness: Though high-quality molds may have a higher initial cost, they offer long-term savings by reducing defects, improving efficiency, and reducing the need for frequent mold replacements. An Injection Mould Company that follows strict quality standards ensures that the investment in molds pays off over time.

The Future of Injection Molding and Mold Makers

The field of Injection Molding is constantly evolving, with advancements in technology driving improvements in mold design and manufacturing techniques. 3D printing, for example, is beginning to play a role in mold making, allowing Mold Makers to quickly prototype and test new designs. This technology could help improve the speed and precision of mold creation, ultimately benefiting the Injection Molding process.

In the future, Injection Mould Companies will continue to focus on enhancing the quality and performance of the molds they create. They will likely invest in even more advanced machinery and tools to ensure the molds they produce meet the ever-increasing demands of precision manufacturing.

The role of an Injection Mould Company in the Injection Molding process cannot be overstated. The quality of the Injection Molds directly impacts the efficiency, consistency, and cost-effectiveness of manufacturing. Skilled Mold Makers who create precise molds are at the heart of this process, ensuring that each part produced meets the highest standards. By adhering to strict quality standards, Injection Mould Companies help ensure that manufacturers can produce high-quality, reliable products on time and within budget.