Engines are the heart of vehicles. Many parts come from precision plastic. Automotive Injection Molds make these parts possible. Skilled Mold Makers design and build these molds. They ensure accuracy and efficiency. This article explores the importance of molds in engine production.

Why Use Automotive Injection Molds for Engine Parts?

1. Precision Manufacturing

Injection molds produce exact shapes. This ensures perfect fit and function.

2. Lightweight Components

Plastic engine parts reduce weight. This improves fuel efficiency.

3. Cost-Effective Production

Molds allow high-volume manufacturing. This lowers costs over time.

4. Durability

Injection-molded parts last longer. They resist heat and wear.

Key Roles of a Mold Maker

1. Custom Design

Every engine part has unique needs. A Mold Maker designs molds to match these specifications.

2. Material Expertise

Choosing the right materials is crucial. A Mold Maker selects materials for strength and durability.

3. High Standards

Quality is essential. Skilled Mold Makers ensure precise molds for reliable parts.

4. Problem Solving

They address design challenges effectively. This improves production outcomes.

Engine Components Made with Injection Molds

1. Valve Covers

Plastic valve covers are lightweight and durable. Injection molds ensure their perfect shape.

2. Oil Pans

Molded oil pans are leak-resistant. They also reduce engine weight.

3. Air Intake Manifolds

These parts control airflow into the engine. Molds ensure smooth and accurate designs.

4. Engine Mounts

Molded mounts absorb vibrations. They provide strength and flexibility.

Materials for Automotive Injection Molds

1. Nylon

Nylon is strong and heat-resistant. It works well for engine parts.

2. Polypropylene

This lightweight material is durable. It reduces the weight of engine components.

3. ABS Plastic

ABS is impact-resistant. It provides strength and reliability.

4. Polycarbonate

This material offers high strength. It withstands extreme conditions.

The Injection Molding Process

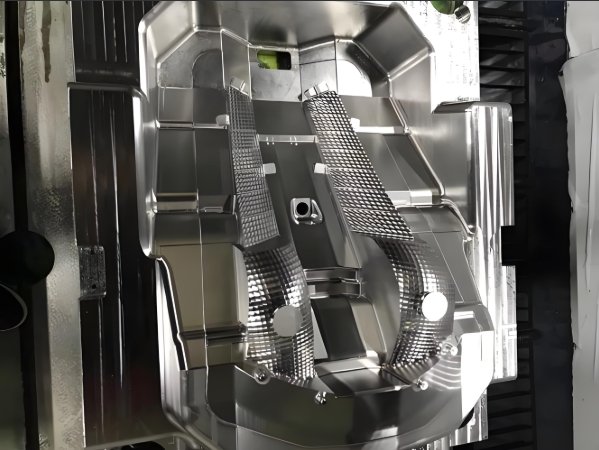

1. Mold Design

The process starts with detailed designs. Mold Makers create precise plans.

2. Material Selection

Plastics are chosen based on part requirements.

3. Injection Phase

Molten plastic is injected into the mold.

4. Cooling and Solidifying

The plastic cools inside the mold. This gives it the desired shape.

5. Trimming and Finishing

Excess material is removed. The final product is ready.

Advantages of Injection Molding for Engine Components

1. Exact Specifications

Injection molding ensures high accuracy. Parts fit perfectly into engine systems.

2. High Strength

Molded parts resist stress and wear.

3. Lightweight Design

Plastic parts reduce engine weight.

4. Cost Efficiency

Mass production reduces overall costs.

Challenges in Making Engine Molds

1. Complex Designs

Engine components are intricate. Molds must meet these complex designs.

2. Material Constraints

Not all plastics suit high temperatures. Careful selection is critical.

3. Maintenance Needs

Molds require regular upkeep. This prevents defects in parts.

Advances in Injection Molding

1. 3D Printing for Prototypes

3D printing speeds up mold development.

2. Automation

Robotic systems enhance accuracy and efficiency.

3. Sustainable Practices

Recycled materials reduce environmental impact.

Applications Beyond Engine Components

1. Exterior Parts

Injection molds create bumpers and grilles.

2. Interior Components

Dashboards and panels come from precision molds.

3. Lighting Systems

Headlight and taillight housings use injection molding.

4. Fuel System Parts

Fuel tanks and filters are molded with precision.

Sustainability in Engine Molding

1. Eco-Friendly Plastics

Bio-based materials are becoming popular.

2. Energy Efficiency

Modern machines consume less energy.

3. Waste Reduction

Injection molding produces minimal waste.

Future Trends in Automotive Injection Molds

1. Smart Manufacturing

Molds will integrate real-time data.

2. Advanced Materials

New materials will improve part performance.

3. Faster Production

Technology will further reduce production time.

Precision is key in engine manufacturing. Automotive Injection Molds provide this precision. Skilled Mold Makers ensure molds meet high standards. They deliver durability and efficiency. As technology advances, injection molds will remain essential. For precise, cost-effective engine parts, these molds are irreplaceable.